LED epitaxial wafer grown on Si substrate and preparation method thereof

An LED epitaxial wafer and substrate technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as epitaxial wafer cracking, reducing LED luminous efficiency, affecting GaN growth quality, etc. The effect of smooth transition of transition and prevention of AlN quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

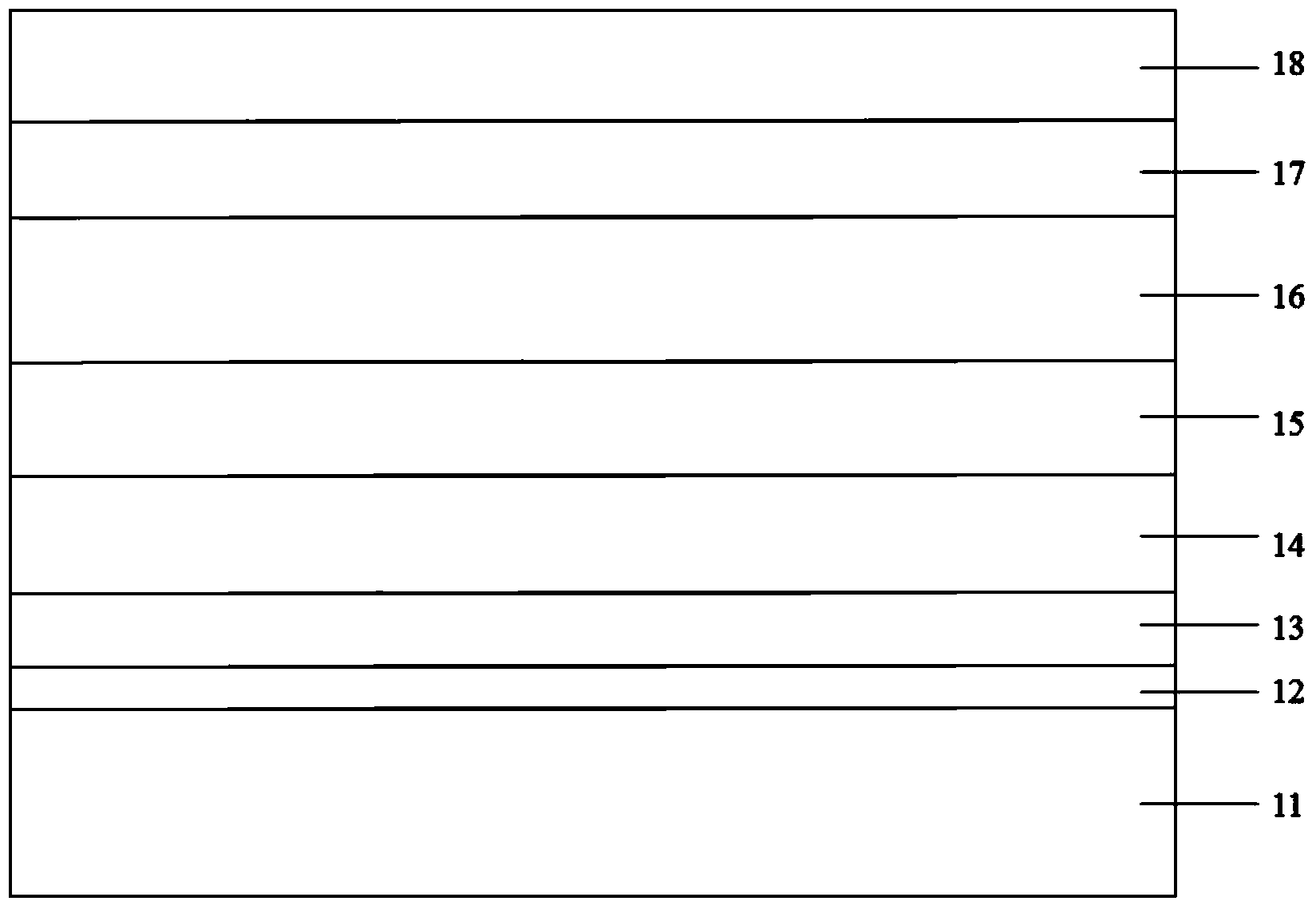

[0037] Please refer to figure 1, the LED epitaxial wafer grown on the Si substrate of the present invention comprises a Si substrate 11, a first AlN buffer layer 12, a second AlN buffer layer 13, an AlGaN step buffer layer 14, a u-GaN layer 15, an n-GaN Layer 16, InGaN / GaN quantum well layer 17 and p-GaN layer 18;

[0038] The above-mentioned LED epitaxial wafer grown on the Si substrate is obtained by the following method:

[0039] (1) Selection of the substrate and its crystal orientation: a Si substrate is used, and the crystal orientation of the (111) plane offset by 0.5° to the (100) direction is selected.

[0040] (2) The first AlN buffer layer is grown by pulsed laser deposition process. The process conditions are as follows: substrate temperature is 650°C, reaction chamber pressure is 1mTorr, V / III ratio is 30, growth rate is 0.5ML / s, and the first AlN The thickness of the buffer layer was 20 nm.

[0041] (3) The second AlN buffer layer was grown by the metal-organi...

Embodiment 2

[0049] The characteristics of this embodiment are:

[0050] The LED epitaxial wafer grown on the Si substrate is obtained by the following method:

[0051] (1) Selection of the substrate and its crystal orientation: a Si substrate is used, and the crystal orientation of the (111) plane offset by 1° to the (100) direction is selected.

[0052] (2) The first AlN buffer layer is grown by the pulsed laser deposition process. The process conditions are as follows: the substrate temperature is 850°C, the reaction chamber pressure is 10mTorr, the V / III ratio is 45, the growth rate is 0.6ML / s, and the first AlN The thickness of the buffer layer was 10 nm.

[0053] (3) The second AlN buffer layer was grown by the metal-organic chemical vapor deposition process. The process conditions were as follows: the substrate temperature was 960 ° C, the reaction chamber pressure was 100 Torr, the V / III ratio was 2500, and the growth rate was 0.1 μm / h. The thickness of the second AlN buffer laye...

Embodiment 3

[0061] This embodiment is modified on the basis of embodiment 1, the difference is that: before growing the AlN buffer layer, the substrate is subjected to surface cleaning and annealing steps in sequence, the specific method is as follows:

[0062] Surface cleaning treatment: ultrasonically clean the Si substrate in acetone solution first, then ultrasonically clean in deionized water; then ultrasonically clean in isopropanone solution; then ultrasonically clean in hydrofluoric acid solution, and then Soak in water; then soak the Si substrate in a mixed solution of sulfuric acid and hydrogen peroxide; finally soak the Si substrate in hydrofluoric acid, rinse with deionized water, and blow dry with nitrogen.

[0063] Annealing treatment: bake the substrate at a high temperature of 900-1000° C. for 3-5 hours.

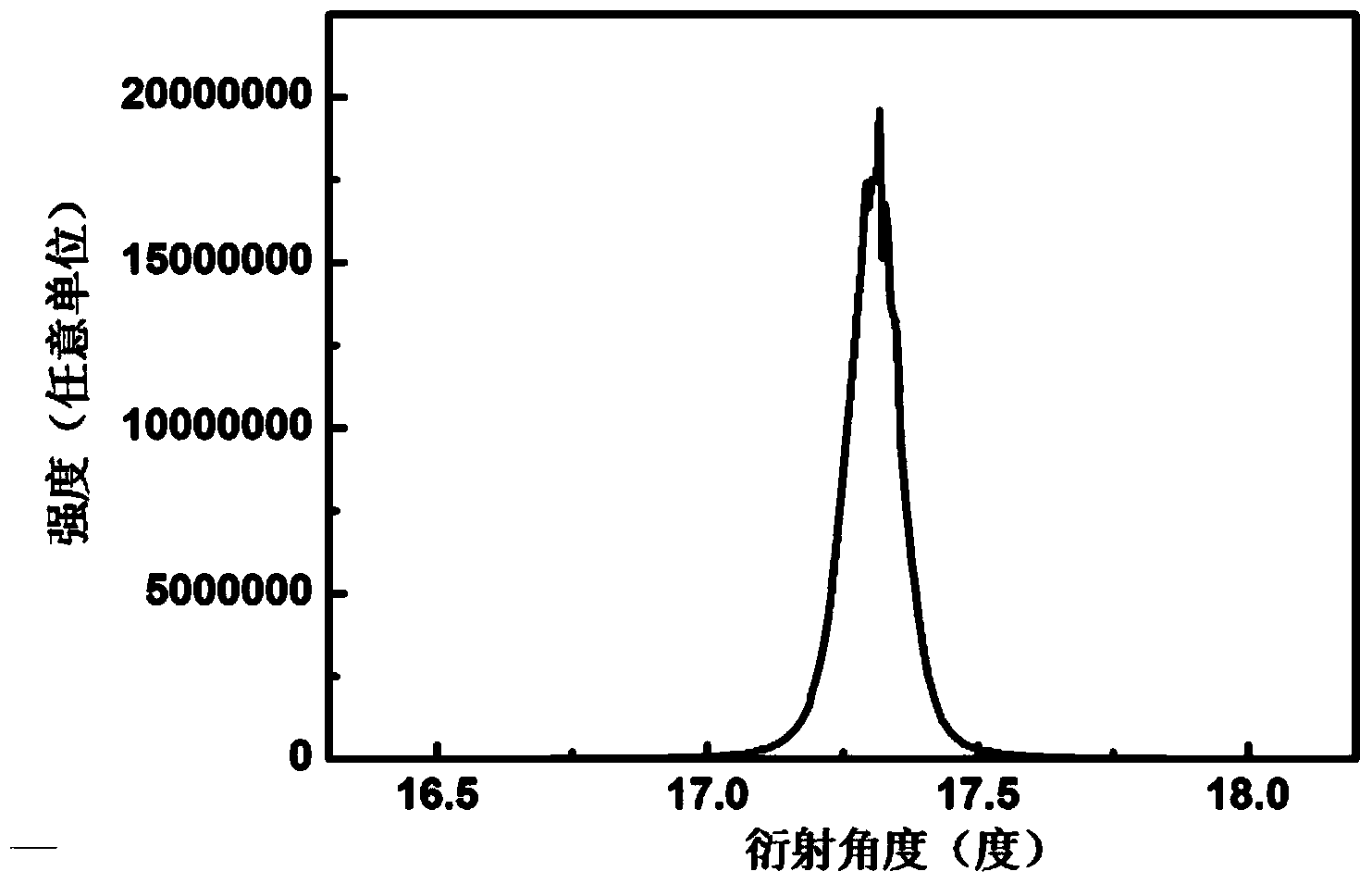

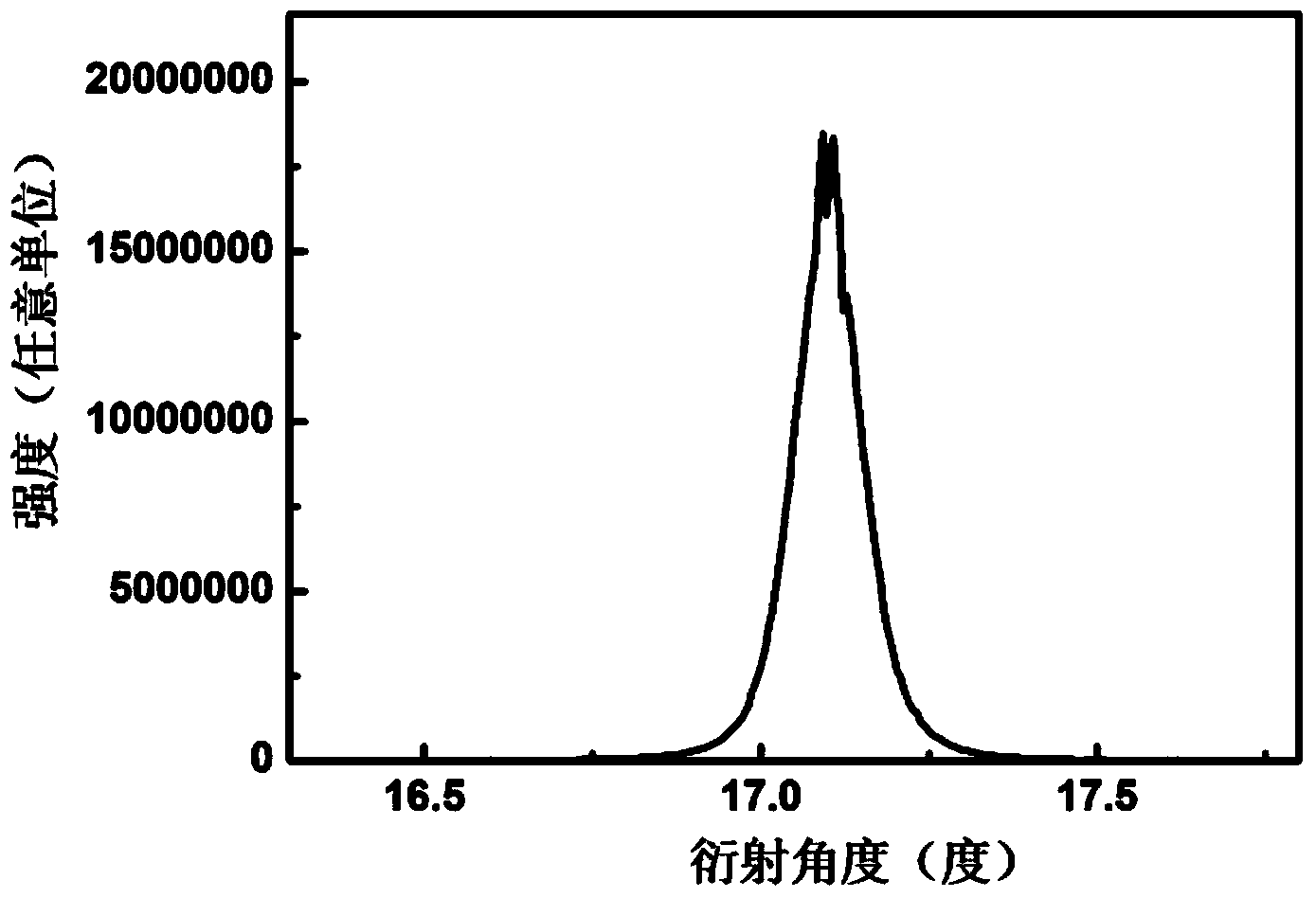

[0064] Please refer to Figure 4 , it can be seen from the X-ray pendulum curve that the half-maximum width (FWHM) value of GaN(002) in the LED epitaxial wafer is 375arc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com