Preparation method and application of magnetic aminated graphene oxide

A technology of amination and graphene, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve problems such as the influence of the adsorption process, achieve high adsorption efficiency, simple preparation process, and extensive sources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

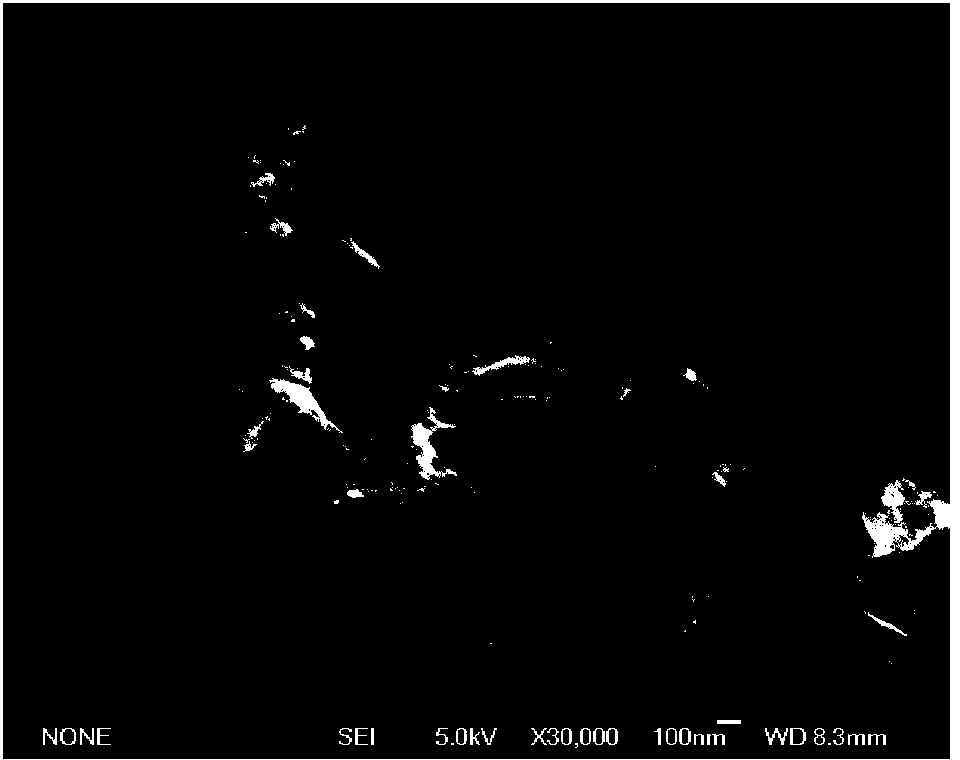

[0021] A preparation method of magnetic aminated graphene oxide of the present invention:

[0022] 6g graphite powder, 5g K 2 S 2 o 8 and 5g P 2 o 5 Add it to 24mL of concentrated sulfuric acid with a mass concentration of 98%, react at 80°C for 4.5 hours, add 1000mL of ultrapure water after cooling to room temperature, wash the obtained product to neutrality after standing for 12 hours, and then dry it at 60°C to obtain Pre-oxidized graphene; the obtained pre-oxidized graphite is added to 240mL mass concentration of 98% concentrated sulfuric acid, then add 5g NaNO 3 and 30g KMnO 4 , react at 0°C for 4 hours, heat up to 35°C for 2 hours, add 500mL of ultrapure water, react at 98°C for 1 hour, then add 1000mL of ultrapure water and 40mL of concentrated H at room temperature 2 o 2 , continue the reaction for 2 hours, wash the obtained product with a HCl solution with a mass concentration of 10%, wash with a large amount of water until neutral, add water to volume, and ult...

Embodiment 2

[0027] The magnetic aminated graphene oxide of the present invention is used to remove heavy metal ions in water, comprising the following steps:

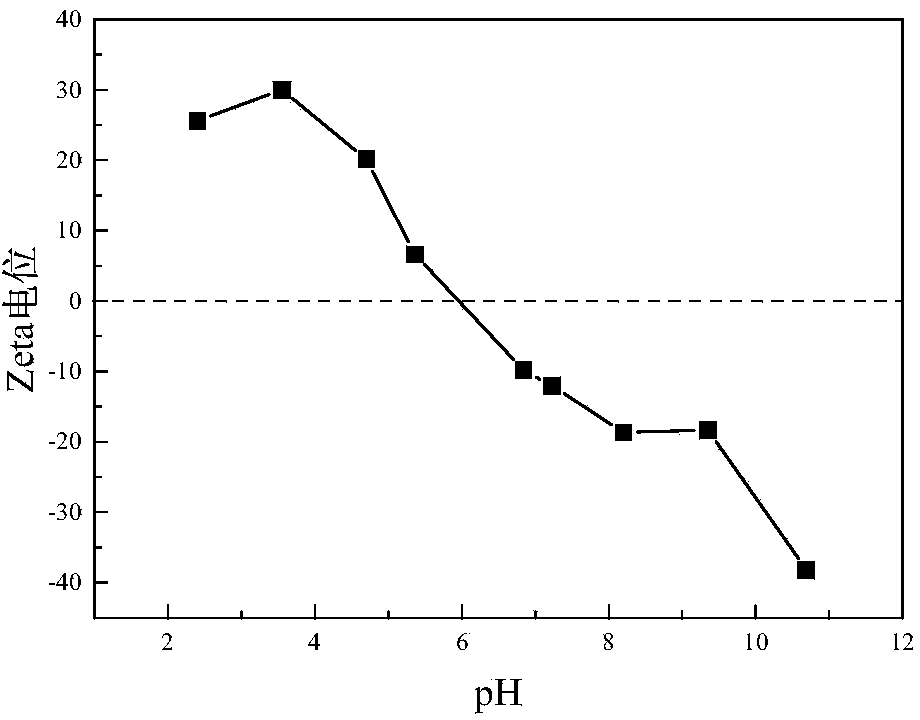

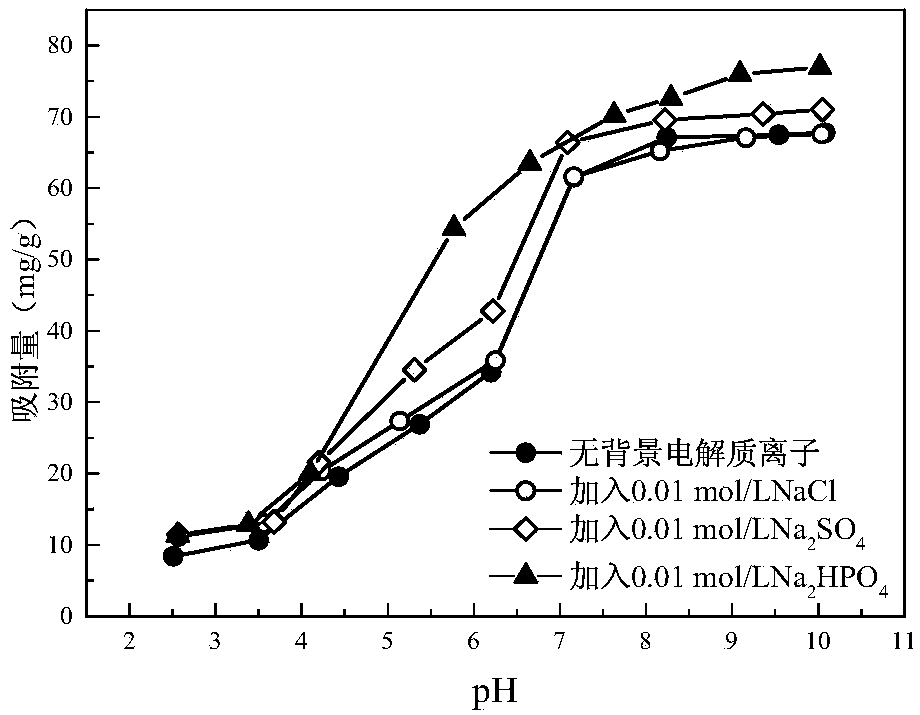

[0028] Take nine volumes of 50mL and an initial concentration of 10mg / L copper wastewater samples to be treated, adjust the pH value with nitric acid or sodium hydroxide in the range of 2 to 11, add the magnetic aminated graphene oxide prepared in Example 1 To the wastewater sample, the amount added per liter of wastewater is 96 mg based on the weight of magnetic aminated graphene oxide. The reactor is placed in a constant temperature water bath shaking box with a rotation speed of 150 rpm, and the temperature is kept at 30 ° C. After shaking for 24 hours, the The magnetic aminated graphene oxide is separated from the solution to complete the treatment of divalent copper wastewater. The concentration of the remaining divalent copper ions in the solution is measured by flame atomic absorption spectrophotometry, and the calculated ad...

Embodiment 3

[0031] The magnetic aminated graphene oxide of the present invention is used to remove heavy metal ions in water, comprising the following steps:

[0032] Take nine volumes of 50 mL and an initial concentration of 10 mg / L copper wastewater samples to be treated, then add a background electrolyte NaCl with a molar concentration of 0.01 mol / L, adjust the pH value with nitric acid or sodium hydroxide within the range of 2 to 11, The magnetic aminated graphene oxide prepared in Example 1 is added to the waste water sample, the amount added per liter of waste water is 96 mg based on the weight of the magnetic aminated graphene oxide, and the reactor is placed in a constant temperature water bath with a rotation speed of 150 rpm to vibrate In the box, the temperature is kept at 30°C, and the magnetic aminated graphene oxide is separated from the solution after oscillating for 24 hours to complete the treatment of divalent copper wastewater. The concentration of the remaining divalen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com