Method for preparing C10-C18 long chain naphthenic hydrocarbon by utilizing furfural compound

A technology of C10-C18 and chain cycloalkanes, which is applied in the preparation of liquid hydrocarbon mixtures, hydrocarbons, hydrocarbons, etc., can solve the problem of serious equipment corrosion, and achieve low cost, high volumetric energy density, and simple steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

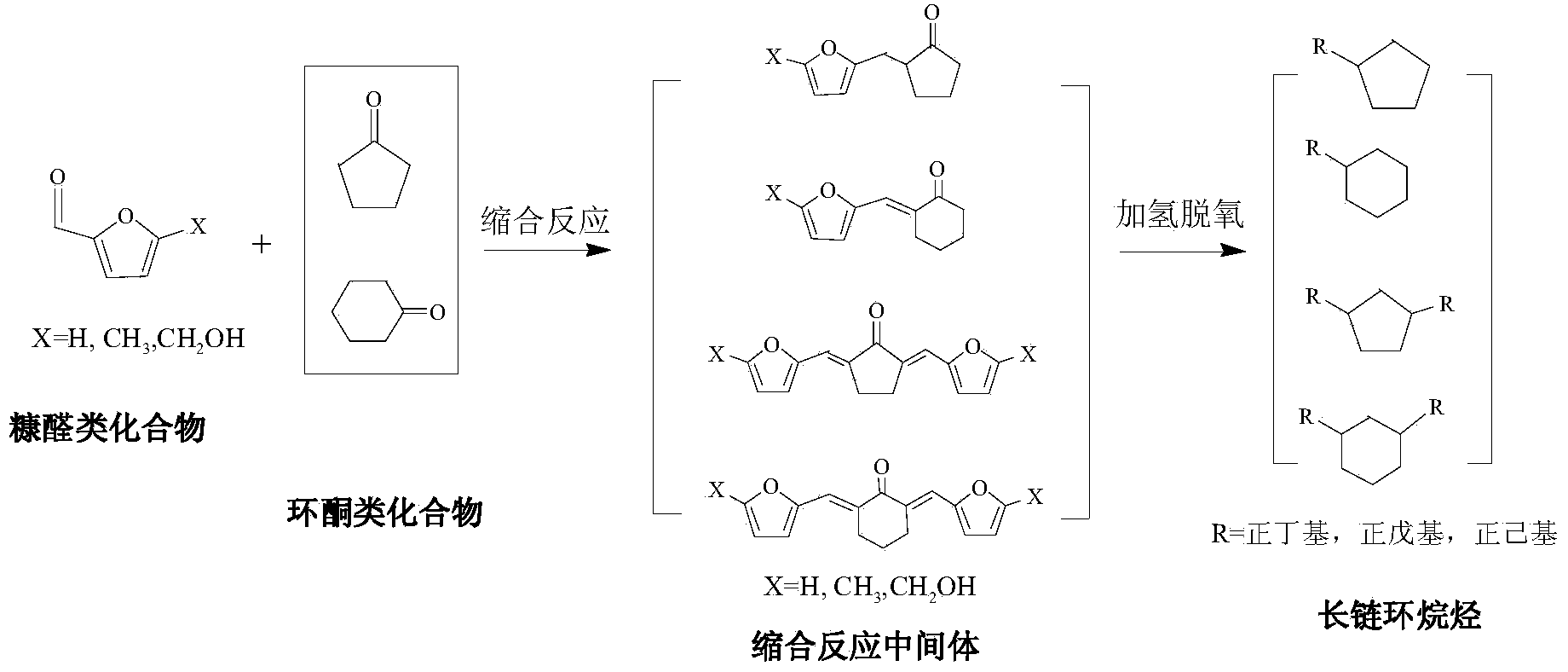

[0022] Such as figure 1 Shown is a synthetic reaction scheme for preparing long-chain naphthenes by using biomass-based furfural derivatives and cyclic ketones in the present invention.

[0023] Table 1 lists the Knoevenagel condensation reactions between different furfural compounds and cyclic ketones, and the yields of condensation products under different catalysts and reaction conditions.

[0024] Table 1 The results of Knoevenagel condensation reaction between furfural compounds and cyclic ketones under different conditions

[0025]

[0026] Table 2 lists the impact of hydrodeoxygenation reaction on the yield of long-chain naphthenes under different catalysts and reaction conditions; the reaction is carried out in a 100ml reactor, and 20ml of water is used as the reaction solvent; the product obtained by Knoevenagel condensation is selected as the reaction raw material , the concentration of the raw material is 10% by mass percentage; the loading amount of the active ...

Embodiment 2

[0030] Using furfural and cyclopentanone as raw materials, the preparation of C 10 -C 18 Long-chain naphthenes:

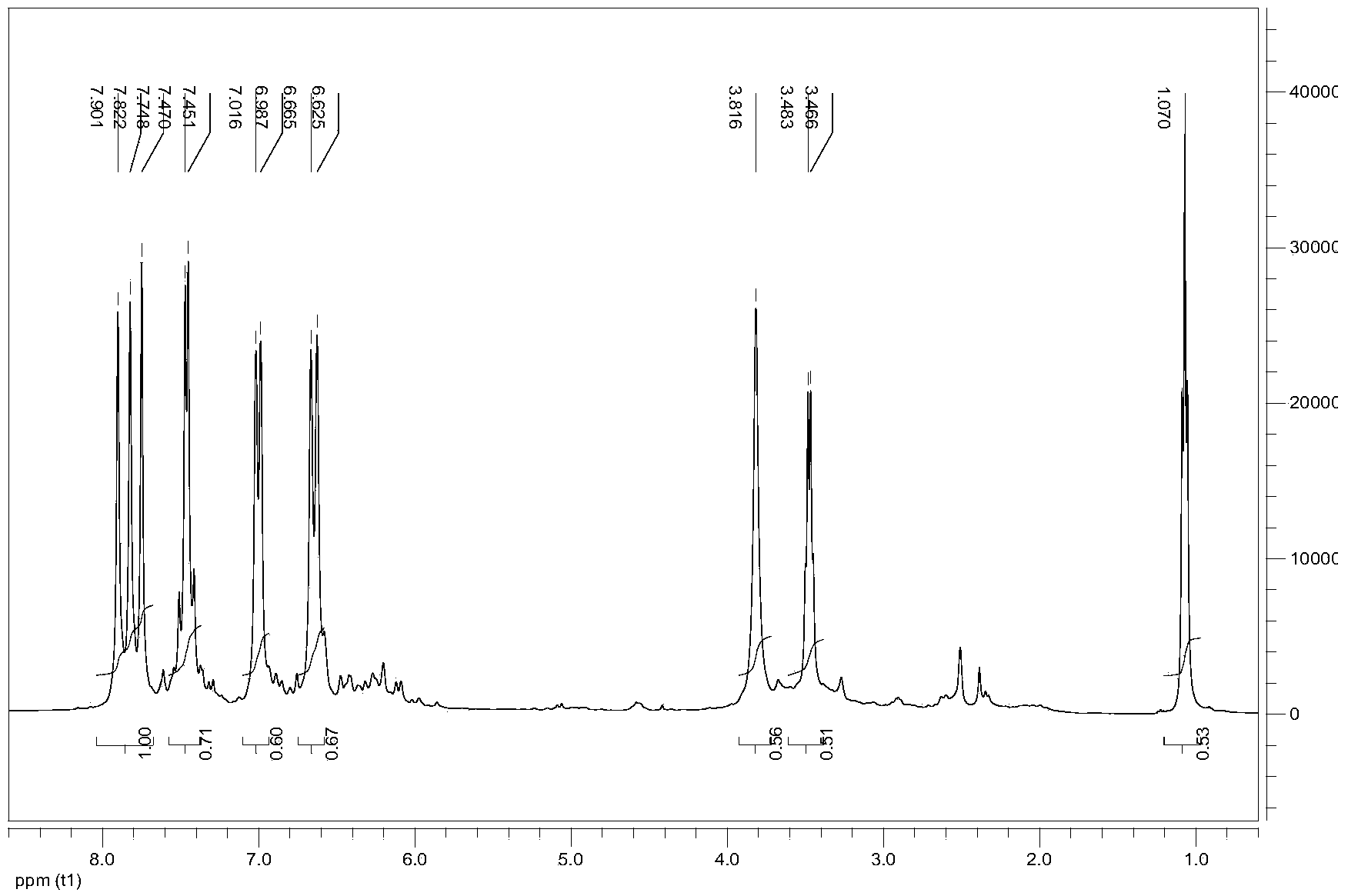

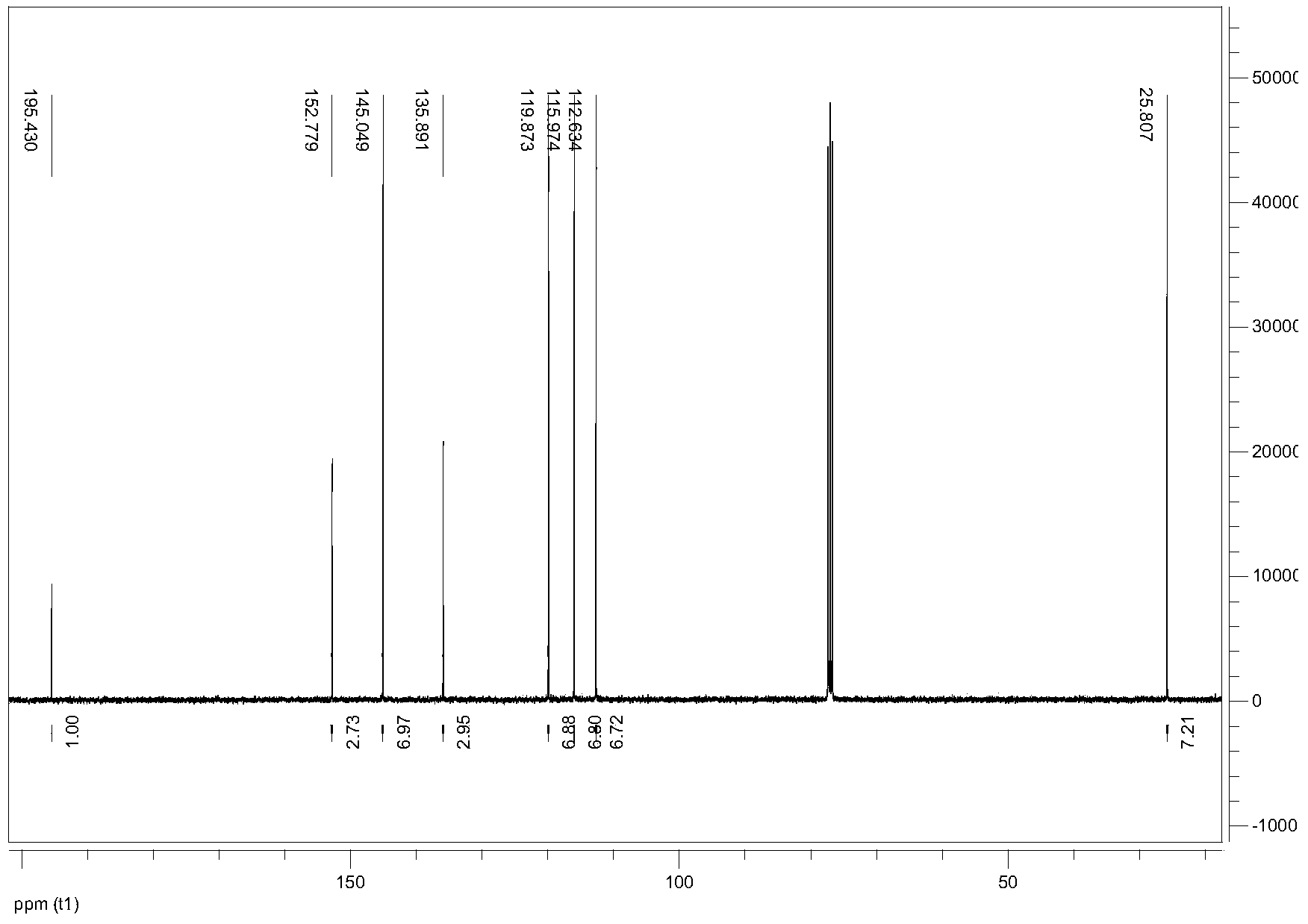

[0031] (1) Knoevenagel condensation reaction: at room temperature, weigh 19.2g furfural and 8.4g cyclopentanone (the molar ratio of furfural to cyclopentanone is 2:1), put them in a 250ml three-necked flask, mix them uniformly, and then Slowly add 10ml of 1mol / L NaOH aqueous solution dropwise under the state, the reaction occurs rapidly and a large amount of yellow solid is generated, filter and wash the solid product with 5% ethanol aqueous solution, dry it in an oven at 50°C, and weigh to obtain 25.2g product. The NMR spectrum of the product is shown in the appendix figure 2 with 3 , the confirmed product is the condensation product of furfural and cyclopentanone 2,5-Bis-furan-2-ylmethylene-cyclopentanone, the structural formula is

[0032](2) Preparation of metal / solid acid catalyst: Weigh 2g of solid zirconium phosphate and add it to 10ml of 5% palladium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com