Titanium alloy thin-wall blade laser-cladding low-stress local orientation cooling restoration method

A technology of laser cladding and directional cooling, which is applied in the field of laser cladding low-stress local directional cooling repair of titanium alloy thin-walled blades. Overheating, over-burning, loss of burn-through strength, and little effect, etc., to achieve uniform microstructure, improve the quality of repair molding, and reduce the effect of the affected area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

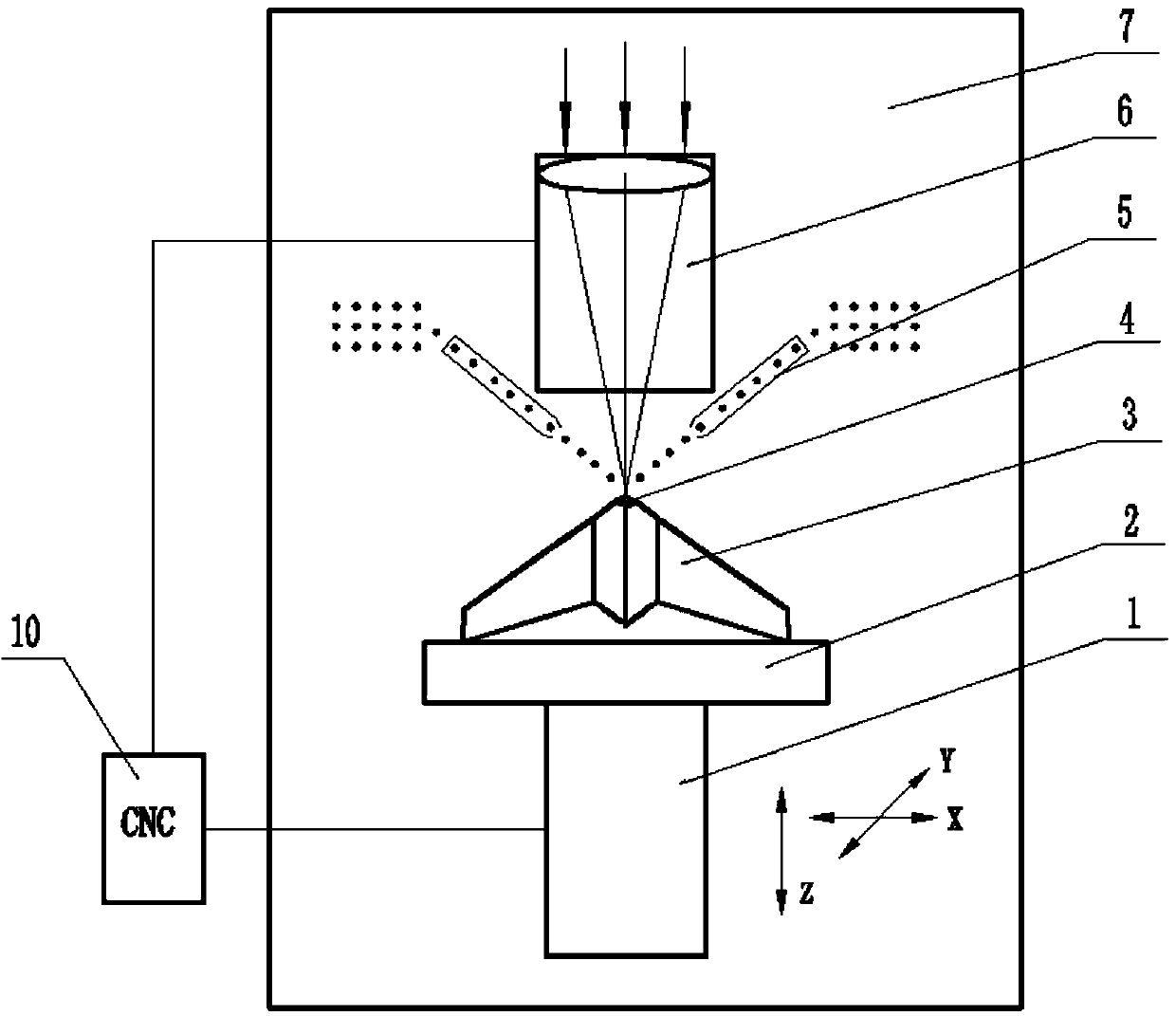

Embodiment 1

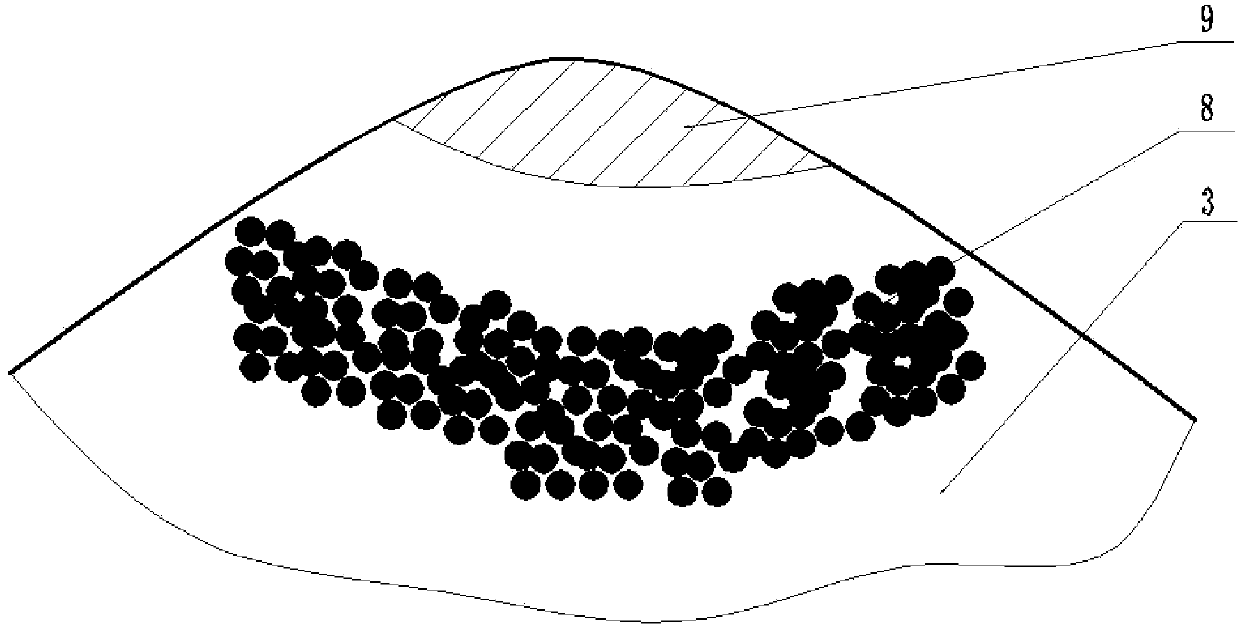

[0038] 1) Mix iron powder with a particle size of 50-100 μm and water glass evenly according to a mass ratio of 3:1 to obtain an iron powder mixture;

[0039] 2) Paste the iron powder mixture on the damaged titanium alloy thin-walled blade, wherein the diameter of the defect repair point is ≤10mm, and the iron powder mixture is pasted at a distance of 3mm from the defect repair point of the titanium alloy thin-walled blade, in a circular distribution, and the defect repair point The ratio of the area to the paste area of the iron powder mixture is 1:1;

[0040] 3) Put the titanium alloy thin-walled blade pasted with the iron powder mixture into a glove box filled with inert gas, and use a powder feeder to transport the titanium alloy powder for repair to the titanium alloy thin-walled blade at a speed of 30g / min. At the defect repair point, a laser with a power of 2000W is used to emit a laser with a spot diameter smaller than or equal to the diameter of the defect repair po...

Embodiment 2

[0043] 1) According to the mass ratio of 5:1, the iron powder with a particle size of 150-200 μm and the paraffin-based binder are uniformly mixed to obtain an iron powder mixture;

[0044] 2) Paste the iron powder mixture on the damaged titanium alloy thin-walled blade, wherein the diameter of the defect repair point is ≤10mm, and the iron powder mixture is pasted at a distance of 8mm from the defect repair point of the titanium alloy thin-walled blade, in a circular distribution, and the defect repair point The ratio of the area to the paste area of the iron powder mixture is 1:2;

[0045] 3) Put the titanium alloy thin-walled blade pasted with the iron powder mixture into a glove box filled with inert gas, and use a powder feeder to transport the titanium alloy powder for repair to the titanium alloy thin-walled blade at a speed of 120g / min. At the defect repair point, a laser with a power of 2000W is used to emit a laser with a spot diameter smaller than or equal to the ...

Embodiment 3

[0048] 1) According to the mass ratio of 4:1, the iron powder with a particle size of 100-150 μm and the polymer binder are uniformly mixed to obtain an iron powder mixture;

[0049] 2) Paste the iron powder mixture on the damaged titanium alloy thin-walled blade, wherein the diameter of the defect repair point is ≤10mm, and the iron powder mixture is pasted at a distance of 5mm from the defect repair point of the titanium alloy thin-walled blade, in a circular distribution, and the defect repair point The ratio of the area to the sticking area of the iron powder mixture is 1:1.5;

[0050] 3) Put the titanium alloy thin-walled blade pasted with the iron powder mixture into a glove box filled with inert gas, and use a powder feeder to transport the titanium alloy powder for repair to the titanium alloy thin-walled blade at a speed of 80g / min. On the defect repair point, a laser with a power of 2000W is used to emit a laser with a spot diameter smaller than or equal to the dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com