Environment-friendly ilmenite collecting agent and preparation method thereof

A collector, ilmenite technology, applied in the direction of solid separation, flotation, etc., can solve the adverse effects of economic, ecological and social benefits of concentrators, the impact of operating environment and ecological environment, and the discharge of wastewater from flotation plants. The impact of meeting the standard and other issues, to achieve the effect of enhancing ore loading, reducing brittleness, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

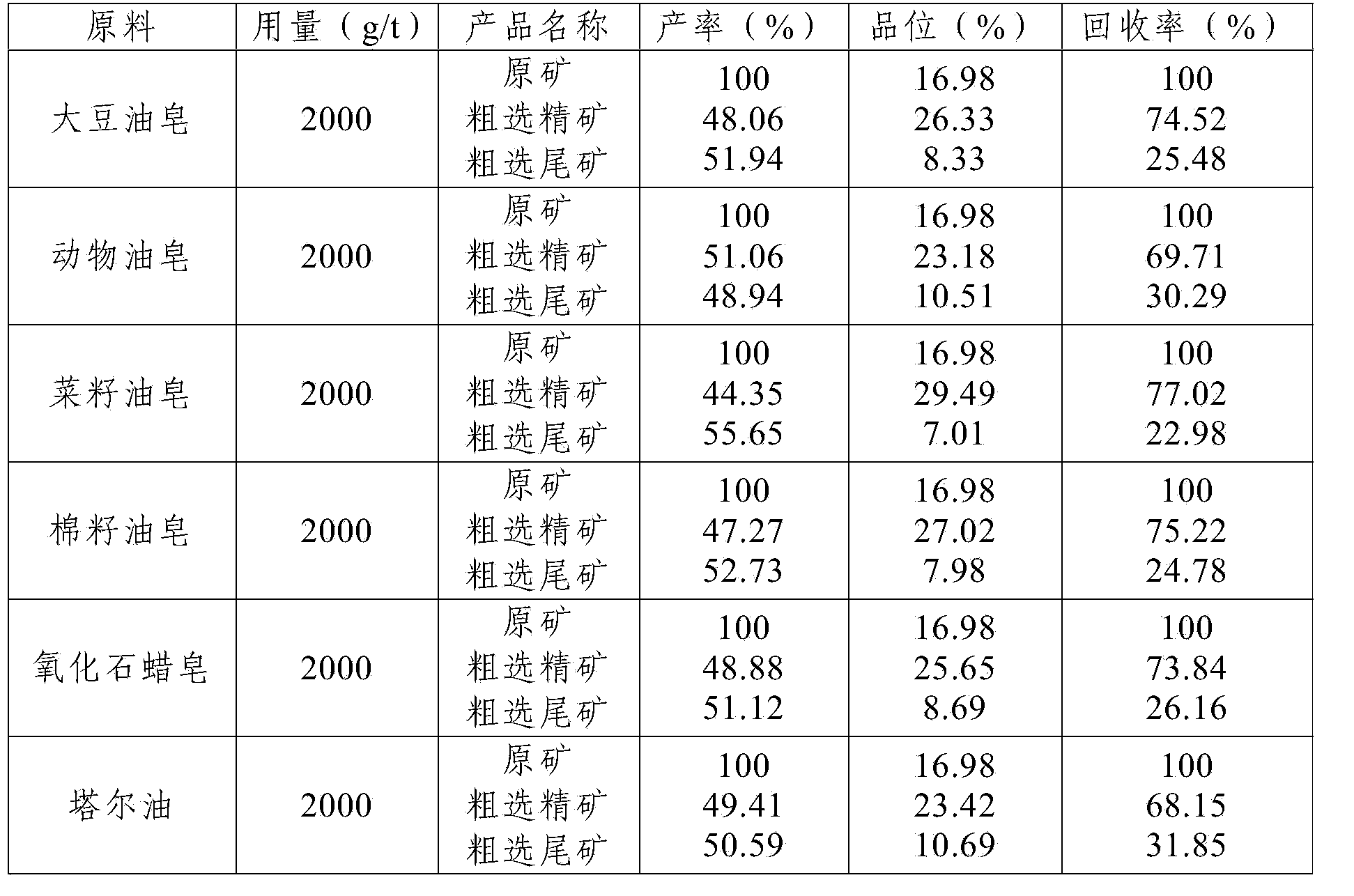

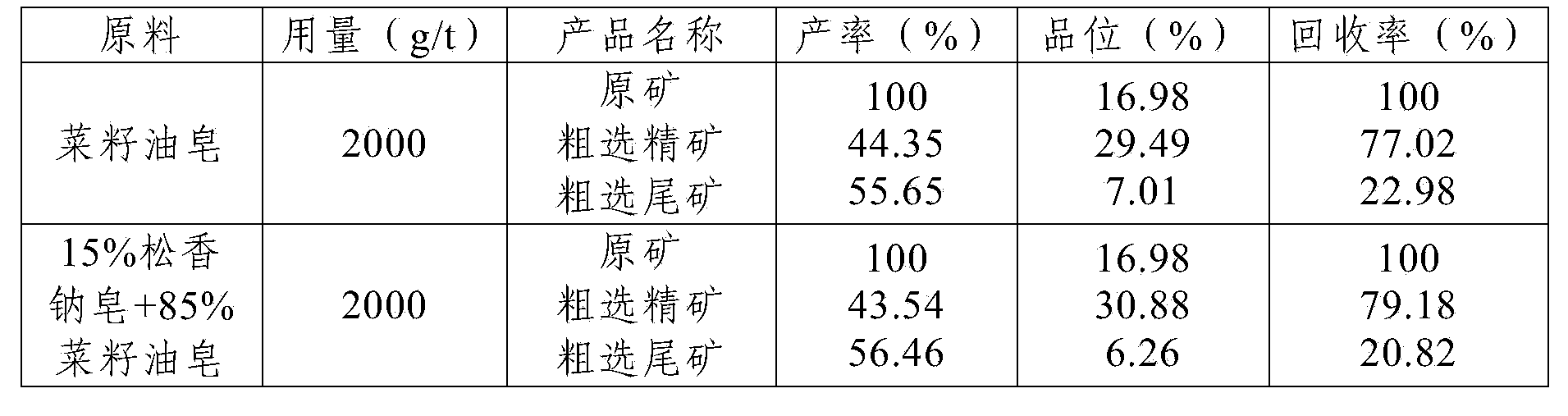

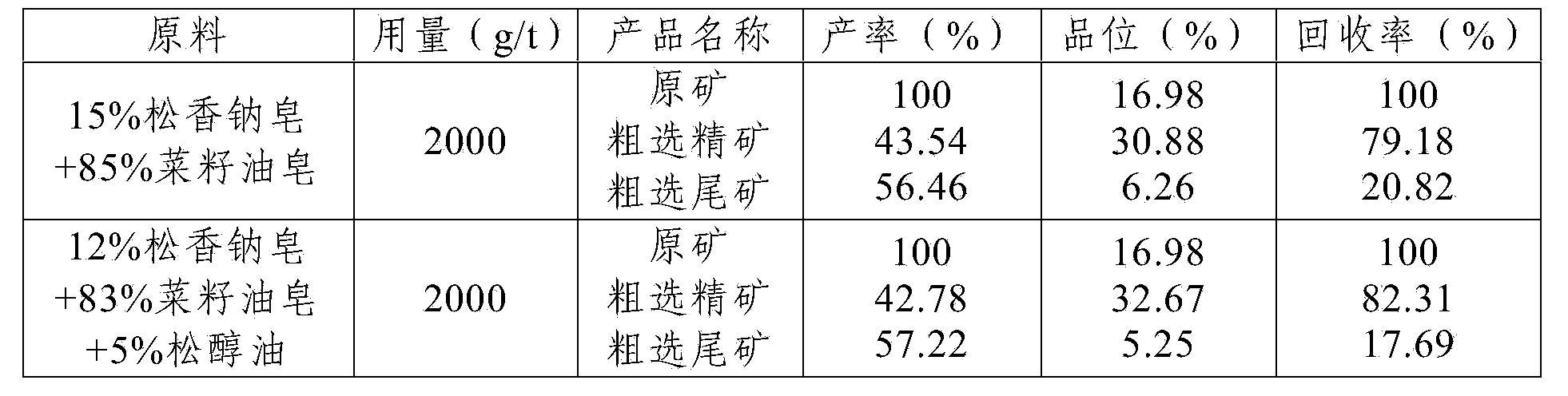

Method used

Image

Examples

Embodiment 1

[0023] The collector of the present embodiment is made of the following raw materials in mass percentage: rapeseed oil soap 60%, rosin sodium soap 15%, pine alcohol oil 5%, fatty alcohol polyoxyethylene ether sodium sulfate 3%, coconut oil fatty acid Diethanolamide 2%, the balance is water; the rapeseed oil soap is an industrial soap bar or soap grain produced by a conventional method using rapeseed oil soapstock; the pH value of the collector is about 10.

[0024] The preparation method of the collector of the present embodiment is: 600kg rapeseed oil soap, 150kg rosin sodium soap, 50kg terpineol oil, 30kg fatty alcohol polyoxyethylene ether sodium sulfate, 20kg coconut oil fatty acid diethanolamide and 150kg water are mixed After heating to 60°C, stir for 1.5h.

Embodiment 2

[0026] The collector of the present embodiment is made of the following raw materials in mass percentage: rapeseed oil soap 55%, rosin sodium soap 12%, pine alcohol oil 6%, fatty alcohol polyoxyethylene ether sodium sulfate 3.5%, coconut oil fatty acid Diethanolamide 2.5%, the balance is water; the rapeseed oil soap is an industrial soap block or soap grain produced by a conventional method using rapeseed oil soap stock; the pH value of the collector is about 8.

[0027] The preparation method of the collector of the present embodiment is: 550kg rapeseed oil soap, 120kg rosin sodium soap, 60kg terpineol oil, 35kg fatty alcohol polyoxyethylene ether sodium sulfate, 25kg coconut oil fatty acid diethanolamide and 210kg water are mixed Then heated to 80°C and stirred for 0.5h.

Embodiment 3

[0029] The collector of the present embodiment is made of the following raw materials in mass percent: rapeseed oil soap 50%, rosin sodium soap 10%, pine alcohol oil 7%, fatty alcohol polyoxyethylene ether sodium sulfate 4%, coconut oil fatty acid Diethanolamide 3%, the balance is water; the rapeseed oil soap is an industrial soap bar or soap grain produced by a conventional method using rapeseed oil soapstock; the pH value of the collector is about 8.

[0030] The preparation method of the collector of the present embodiment is: 500kg rapeseed oil soap, 100kg rosin sodium soap, 70kg terpineol oil, 40kg fatty alcohol polyoxyethylene ether sodium sulfate, 30kg coconut oil fatty acid diethanolamide and 260kg water are mixed Then heated to 70°C and stirred for 1h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com