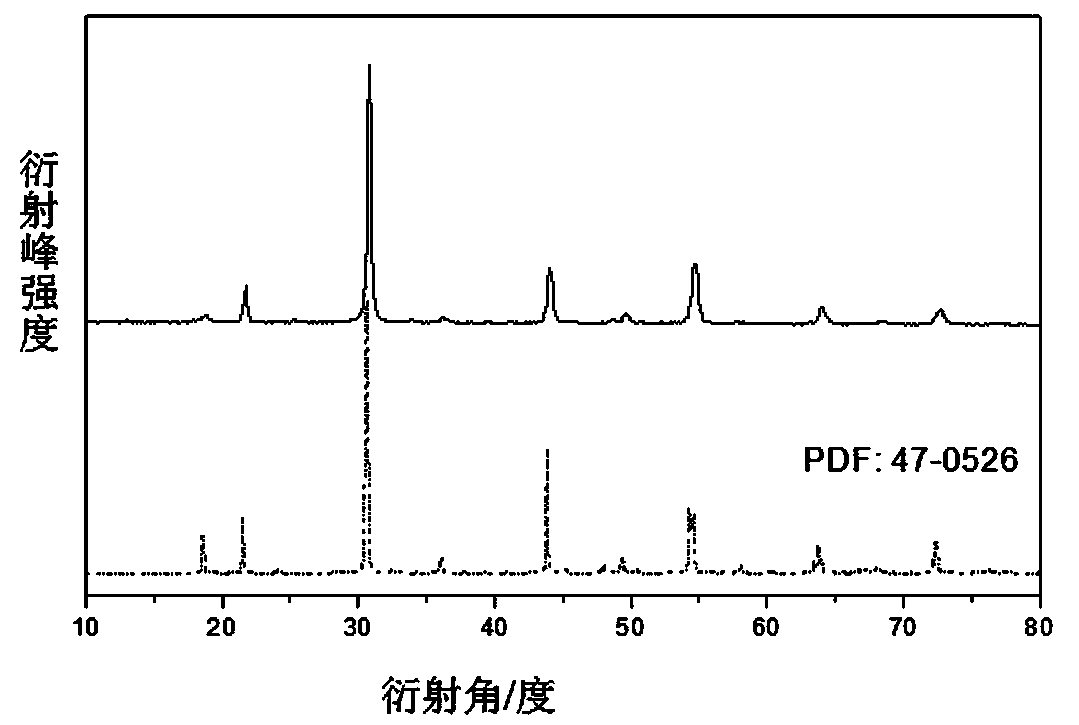

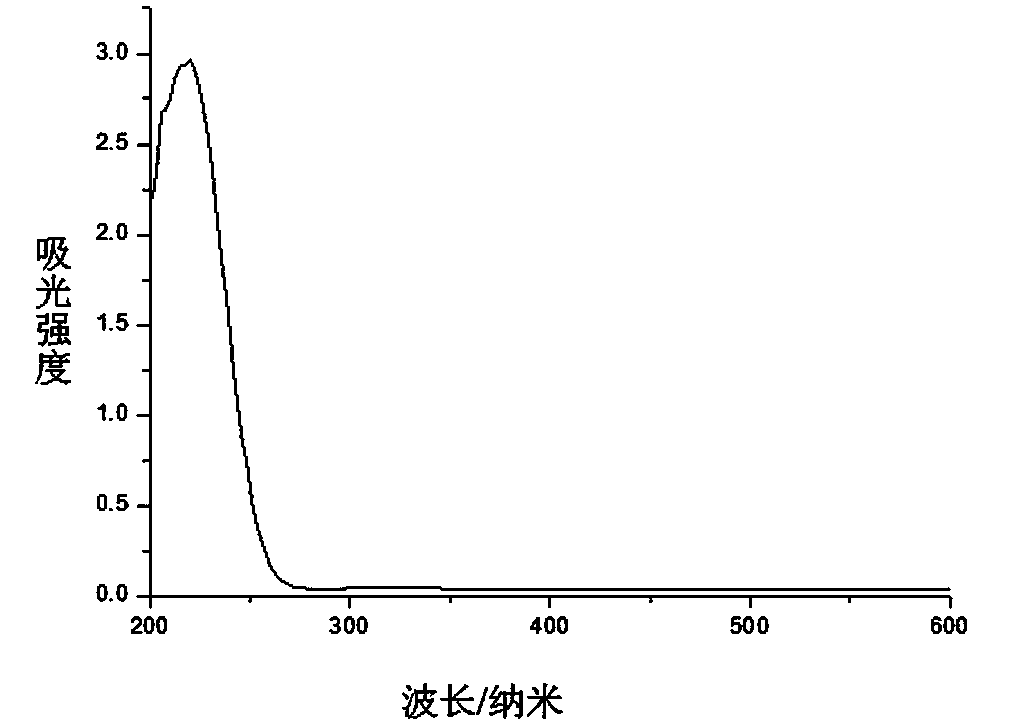

Burning method for preparing Sr2YTaO6 powder

A technology of strontium tantalate and combustion method, which is applied in chemical instruments and methods, tantalum compounds, inorganic chemistry, etc., can solve the problems of long time consumption, and achieve the effect of low preparation cost, low impurity content and meeting requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

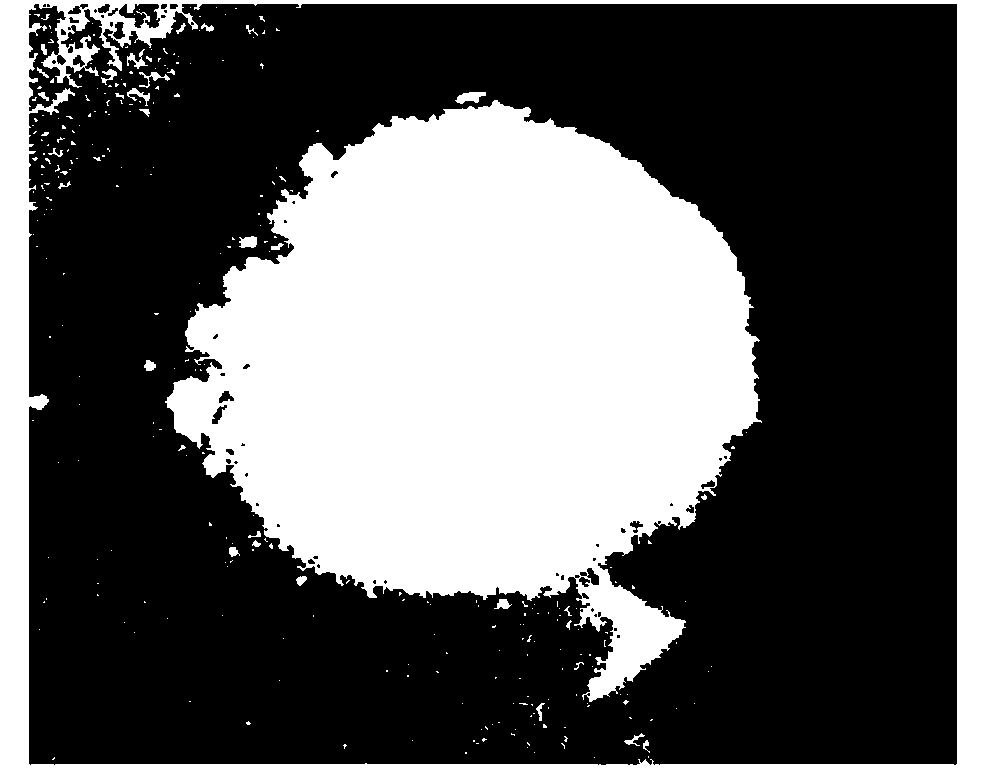

Embodiment 1

[0029] Accurately weigh strontium nitrate, yttrium nitrate, tantalum pentachloride and urea according to the molar ratio of 2:1:1:10, put them into methanol aqueous solution (alcohol-water volume ratio 1:1) and stir to dissolve for more than 30 minutes . Put the above-mentioned mixture into a large crucible and put it directly into a muffle furnace. The heating rate of the programmed temperature rise is 10 °C / min, the high temperature setting temperature is 800 °C, and the holding time of the high temperature stage is 10 h. After natural cooling, That is to get strontium yttrium tantalate powder, the product purity is not less than 99.86%, impurity content: carbon is less than 0.06%; chlorine is less than 0.01%.

Embodiment 2

[0031] Accurately weigh strontium nitrate, yttrium nitrate, tantalum pentachloride and urea according to the molar ratio of 2:1:1:20, put them into methanol aqueous solution (volume ratio of alcohol to water: 2:1) and stir to dissolve for more than 30 minutes . Put the above-mentioned mixture into a large crucible and put it directly into a muffle furnace. The heating rate of the programmed temperature rise is 10 °C / min, the high temperature setting temperature is 900 °C, and the holding time of the high temperature stage is 10 h. After natural cooling, That is to get strontium yttrium tantalate powder, the product purity is not less than 99.85%, impurity content: carbon is less than 0.07%; chlorine is less than 0.01%.

Embodiment 3

[0033] Accurately weigh strontium nitrate, yttrium nitrate, tantalum pentachloride and citric acid in a molar ratio of 2:1:1:20 and put them into methanol water solution (volume ratio of alcohol to water: 1:1) to stir and dissolve for more than 30 minutes. minute. Put the above-mentioned mixture into a large crucible and put it directly into a muffle furnace. The heating rate of the programmed temperature rise is 10 °C / min, the high temperature setting temperature is 800 °C, and the holding time of the high temperature stage is 10 h. After natural cooling, That is to get strontium yttrium tantalate powder, the product purity is not less than 99.82%, impurity content: carbon is less than 0.09%; chlorine is less than 0.01%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com