A superhydrophobic surface with hydrophobic vapor function and preparation method thereof

A super-hydrophobic surface, water vapor technology, applied in coatings, epoxy coatings, polyester coatings, etc., can solve problems such as being unsuitable for large-area treatment and application, cumbersome preparation process, and limitations in the use of substrates, to avoid Ink drop splash, simple preparation process, and the effect of improving the insecticidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

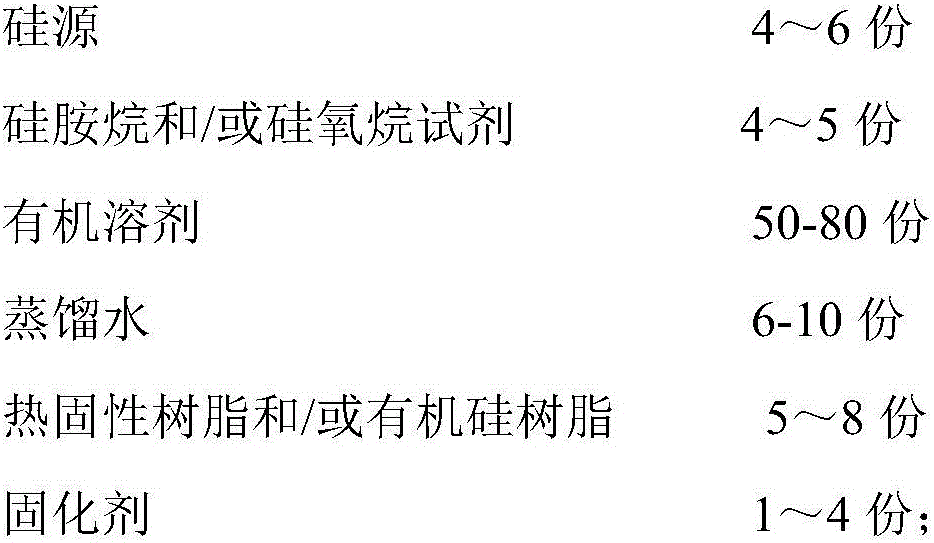

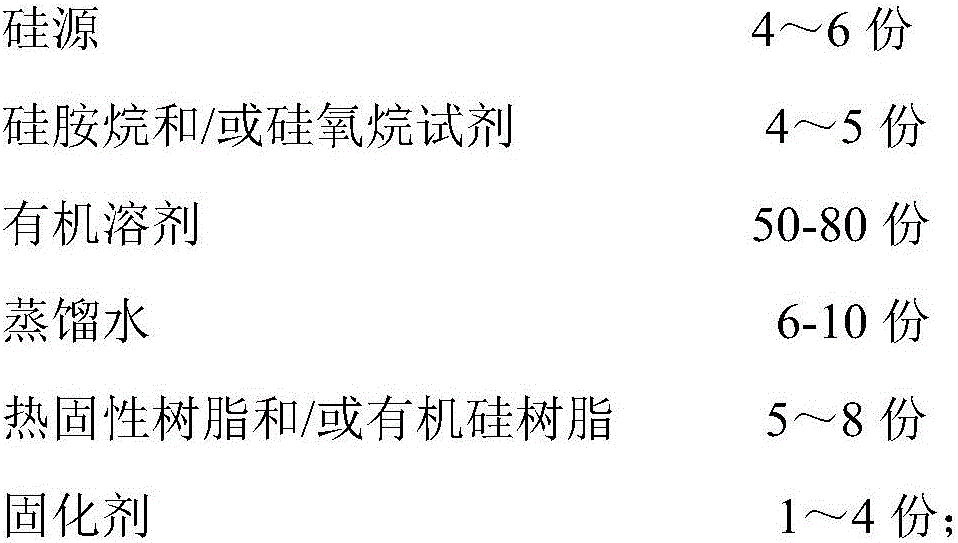

Method used

Image

Examples

Embodiment 1

[0037] (1) 5.0g of ethyl orthosilicate was added to 68.0g of propanol, and after stirring for 30min at a rotating speed of 400r / min, 6.0g of distilled water, 1.0g of ammonia water, and 4.0g of methyltrimethoxysilane were added. Stir at 400r / min for 140min to obtain a silica sol solution;

[0038] (2) Add 8.0g of phenolic resin resin to the above prepared silica sol solution, stir at a rotating speed of 200r / min, the heating temperature is 60°C, after complete dissolution, add 1.1g of hexamethylenetetramine, at 200r / min Continue stirring at a rotating speed of / min to obtain a composite resin mixed solution, which is left to stand for use;

[0039] (3) The surface of the glass slide is pretreated and dried, and it is ready for use. The composite resin mixed solution prepared in (2) is coated on the treated glass slide with a size of 76mm*26mm, the surface is dried at room temperature, and then dried at 70 ° C for 2 hours, to obtain a hydrophobic vapor function. superhydrophob...

Embodiment 2

[0042] (1) Add 5.4g of tetraethyl orthosilicate to 75.0 g of ethanol, stir at 400r / min for 30min, add 8.2g of distilled water, 4.2g of hexamethyldisilazane, and continue at 400r / min Stir for 120min to obtain the silica sol solution;

[0043] (2) Add 6.8g of epoxy resin (E44) to the above-prepared silica sol, stir at 200r / min, and heat at 55°C. After it is completely dissolved, add 1.5g of polyamide and 1.0 ethylene glycol Amine, continue to stir under the rotating speed of 200r / min, obtain the composite resin mixed solution, leave standstill for use;

[0044] (3) Dried after the surface pretreatment of the copper sheet, ready for use. Coat the composite resin mixed solution prepared in (2) on the treated copper sheet (5mm*3mm), dry the surface at room temperature, and then bake at 100°C for 2 hours to obtain a superhydrophobic surface;

[0045] (4) The superhydrophobic surface obtained in step (3) is tested for hydrophobicity and water vapor performance, and the surface is ...

Embodiment 3

[0047] (1) Add 4.6g of tetraethyl orthosilicate to 60.0g of isopropanol, after stirring for 30min at a speed of 400r / min, add 7.8g of distilled water, 0.5g of ammonia water, 4.6g of trimethylchlorosilane, and continue to Stir at a speed of 400r / min for 120min to obtain a silica sol solution;

[0048] (2) Add 5.5g of epoxy resin (E44) and amino-terminated polydimethylsiloxane with a mass ratio of 2:1 to the above prepared silica sol, stir at a speed of 200r / min, and heat The temperature is 60°C. After it is completely dissolved, add 1.8g of hexamethylenediaminetriethylenetetramine and continue stirring to obtain a composite resin mixed solution, which is left to stand for use;

[0049] (3) Dry the surface of the plastic sheet after pretreatment, and set aside. Apply the composite resin mixed solution prepared in (2) on the surface of the treated plastic sheet (10mm*5mm), dry it at room temperature, and then bake it at 85°C for 2 hours to obtain a superhydrophobic surface with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com