Preparation method for p-type Bi0.5Sb1.5Te3-based nano-porous thermoelectric composite material

A bi0.5sb1.5te3, nano-porous technology, applied in the field of thermoelectric composite material preparation, can solve the problems of high cost, low efficiency, and low conversion efficiency of thermoelectric materials, and achieve the effect of low cost, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

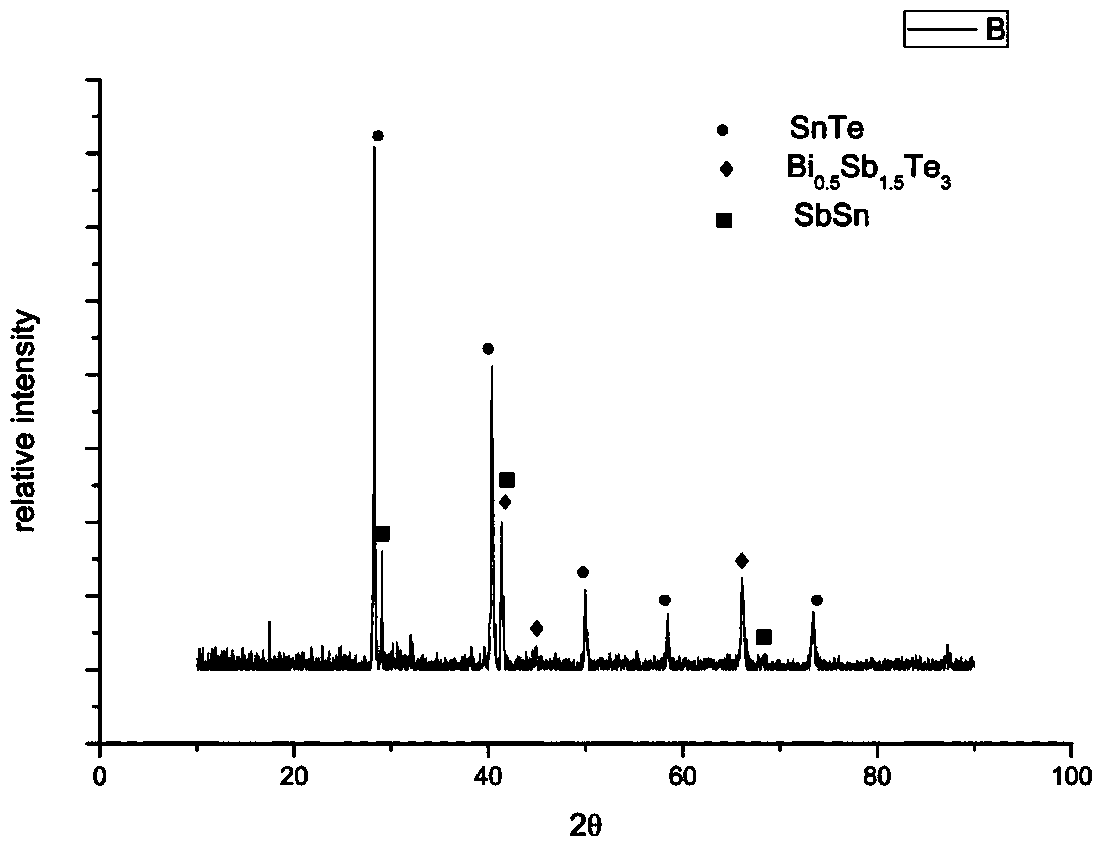

[0016] The p-type Bi of the present invention 0.5 Sb 1.5 Te 3 The preparation method of base nanoporous thermoelectric composite material comprises the following steps:

[0017] 1) Spread 3-5μm Sn solder paste on the p-type thermoelectric material Bi 0.5 Sb 1.5 Te 3 Put it on the heating platform, and carry out the liquid phase wetting reaction in the protective atmosphere of Ar gas at 260°C, the reaction time is 5-10min, so as to form a layer of Sn solder paste and the product SnTe-SbSn Uniform mixed layer; react under Ar gas atmosphere to prevent tin oxidation, the thickness of the mixed layer reaction product SnTe-SbSn and the microstructure of the product can be adjusted through the reaction time and temperature;

[0018] 2), the thermoelectric material Bi after the reaction in step 1) 0.5 Sb 1.5 Te 3 The reaction pair composed of Sn solder paste was placed in a beaker filled with a 10% nitric acid solution, and then ultrasonically oscillated in a water bath enviro...

Embodiment 1

[0021] 1. Spread the 3-5μm Sn solder paste on the p-type thermoelectric material Bi with a size of 5×5×1mm 0.5 Sb 1.5 Te 3 above, and put it on the heating platform, at 260 ℃, carry out the liquid phase wetting reaction, the reaction time is 5min, so as to form a layer of uniform mixed layer of Sn material and product SnTe-SbSn, such as figure 1 shown.

[0022] 2. The fully reacted thermoelectric material Bi in step 1 0.5 Sb 1.5 Te 3 For the reaction with solder Sn, place it in a beaker filled with 10% nitric acid solution, and perform ultrasonic vibration, where the solution temperature is 80°C, and the pickling time is 30min. Among them, the solder Sn and the Sn included in the formation will be corroded by acid, so as to form uniformly distributed pores with a size of 200-500nm.

[0023] 3. Wash repeatedly with distilled water to obtain p-type Bi in step 2 0.5 Sb 1.5 Te 3 / Porous SnTe-SbSn composite thermoelectric material, because the Sn material reacts in the li...

Embodiment 2

[0025]1. Spread the 3-5μm Sn solder paste on the p-type thermoelectric material Bi with a size of 5×5×1mm 0.5 Sb 1.5 Te 3 Above, put it on the heating platform, and carry out the liquid phase wetting reaction at 260 °C, the reaction time is 5min, so as to form a uniform mixed layer of Sn material and product SnTe-SbSn, such as image 3 shown.

[0026] 2. The fully reacted thermoelectric material Bi in step 1 0.5 Sb 1.5 Te 3 For the reaction with Sn solder paste, place it in a beaker filled with 10% nitric acid solution, and perform ultrasonic vibration, wherein the solution temperature is 80°C, and the pickling time is 30min. Among them, the solder Sn and the Sn included in the formation will be corroded by acid, so as to form uniformly distributed pores with a size of 200-500 μm.

[0027] 3. Wash repeatedly with distilled water to obtain p-type Bi in step 2 0.5 Sb 1.5 Te 3 / Porous SnTe-SbSn composite thermoelectric material, because the Sn material reacts in the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com