Organic electroluminescent device light-emitting layer, manufacturing method of organic electroluminescent device light-emitting layer and application of organic electroluminescent device light-emitting layer

A technology of electroluminescent devices and light-emitting layers, which is applied in the fields of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve problems such as ligand dissociation and unfavorable device performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Synthesis of host material Czpzpy

[0085]

[0086] (1) Synthesis of intermediate Brpzpy: Dissolve pyrazole (20mmol, 1.36g) in 1,4-dioxane (60mL), add potassium tert-butoxide (22mmol, 2.47g) and 2,6-dioxane in sequence Bromopyridine (20mmol, 4.74g). The reaction mixture was stirred at reflux for 48 hours and then quenched with 10 mL of water. After spin-drying the organic solvent, 300 mL of water was added to the reaction mixture and extracted several times with dichloromethane. The organic phases were combined, washed several times with saturated brine and dried over anhydrous sodium sulfate. The solvent was spin-dried and passed through the column to obtain a white solid Brpzpy (3.8 g, yield: 85%). Utilize nuclear magnetic resonance spectrometer to carry out analysis, the result is as follows: 1 H NMR (400MHz, CDCl 3 ): δ8.54(d, J=2.6Hz, 1H), 7.93(d, J=8.1Hz, 1H), 7.74(s, 1H), 7.66(t, J=7.9Hz, 1H), 7.36(d , J=7.7Hz, 1H), 6.47(s, 1H).

[0087] (2) Synthesis of...

Embodiment 2

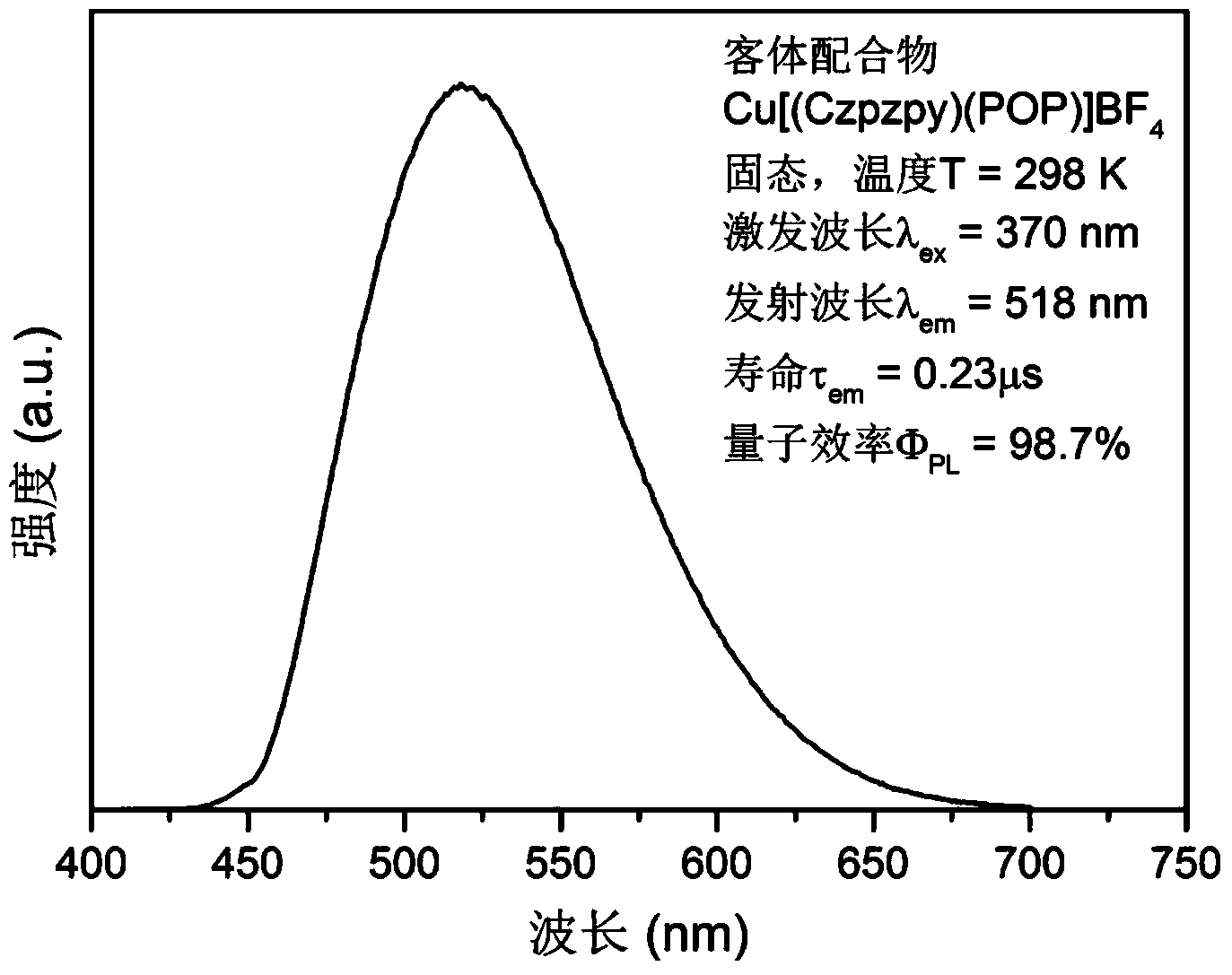

[0090] Guest complex [Cu(Czpzpy)(POP)]BF 4

[0091]

[0092] Preparation: Under nitrogen atmosphere, [Cu(CH 3 EN) 4 ] BF 4 (0.314g, 1mmol) and bis(2-diphenylphosphinophenyl) ether (POP, 0.538g, 1mmol) were added to 10mL of dichloromethane, and after stirring at room temperature for half an hour, the ligand Czpzpy (0.145g, 1mmol ) was added to the solution and stirring was continued for 1 hour. After filtering, the solvent was spin-dried and recrystallized with dichloromethane / ether to obtain light yellow transparent crystals. Utilize nuclear magnetic resonance spectrometer and elemental analyzer to analyze gained complex, the result is as follows:

[0093] 1 H NMR (400MHz, CDCl 3 ):δ8.94(s,1H),8.44(s,1H),8.28(s,1H),8.09(d,J=7.9Hz,2H),7.67–7.27(m,9H),7.25–6.97( m, 11H), 6.91(t, J=7.5Hz, 3H), 6.71–6.18(m, 14H). 31 P NMR: -11.99 (s). Anal. Calcd for C 56 h 42 BCuF 4 N 4 OP 2 : C, 67.31; H, 4.24; N, 5.61. Found: C, 67.04; H, 4.24; N, 5.54.

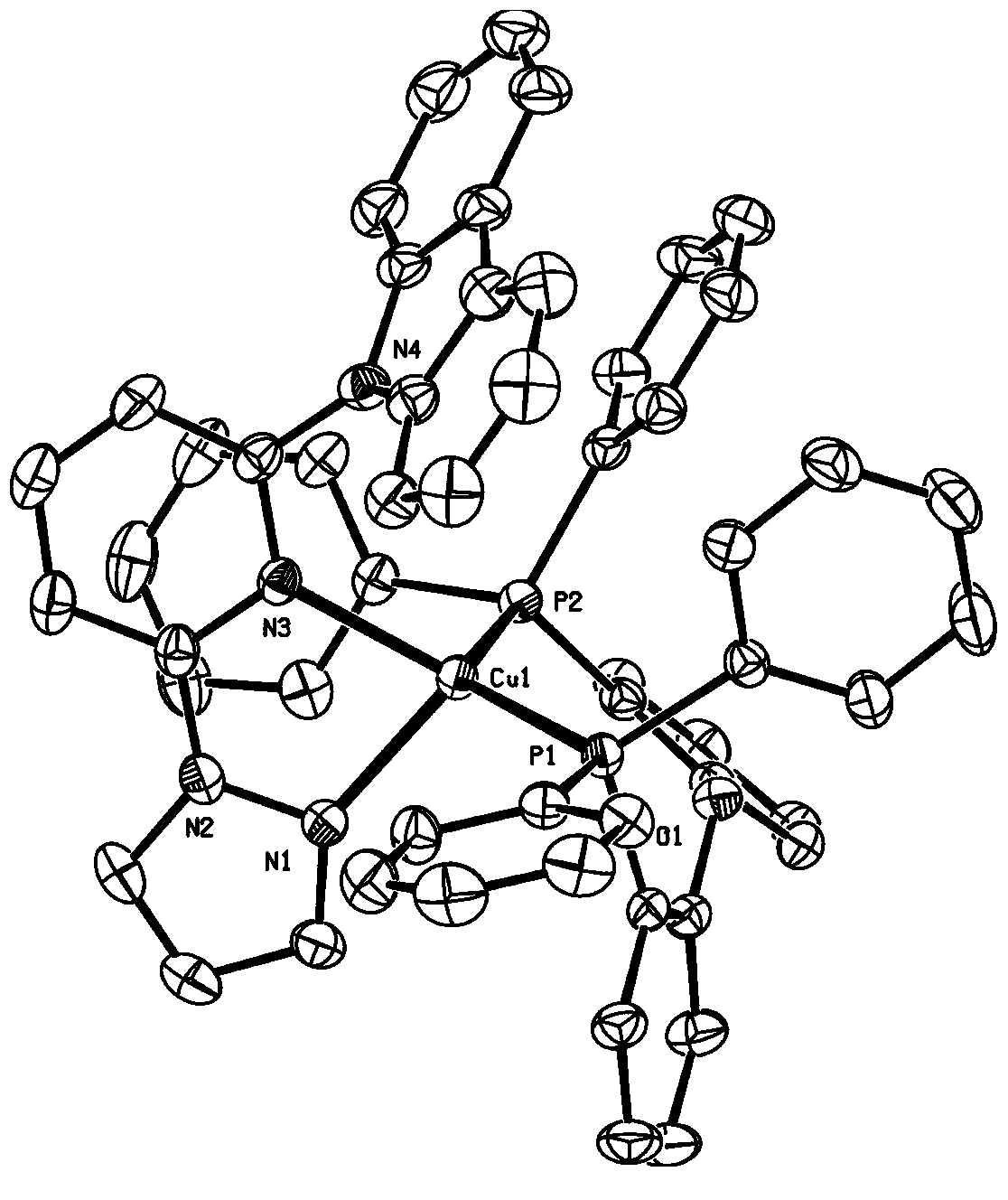

[0094] Crystal struc...

Embodiment 3

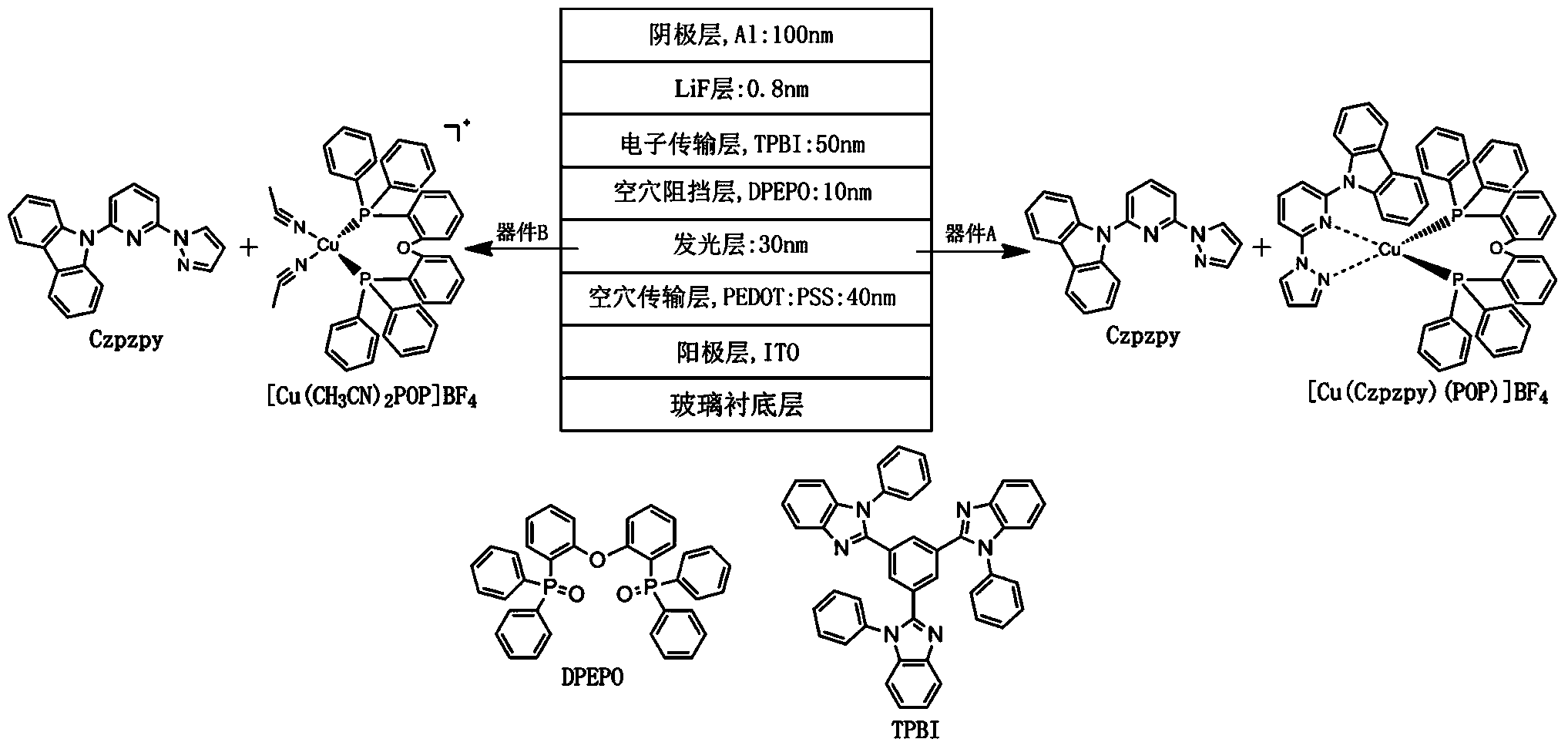

[0097] Utilize the host material described in Example 1 and the mixture of the guest complex described in Example 2 to spin-coat the OLED device (device A) that prepares light-emitting layer

[0098] The preparation method of OLED device A is as follows: spin-coat a layer of PEDOT:PSS (spin for 1 minute, thickness is 40nm) on the clean ITO glass surface under the condition of rotation speed of 3000 rpm, and then dry at 140°C for 20 minutes. 2mg of the guest complex [Cu(Czpzpy)(POP)]BF 4 and 8 mg of Czpzpy were dissolved in 1.8 mL of dichloromethane, and the mixture was spin-coated on the surface of a glass electrode modified by PEDOT:PSS under the condition of a rotating speed of 1500 rpm (rotating for 1 minute) and dried under high vacuum for 1 Hours later, a hole blocking layer (DPEPO) of 10 nm, an electron transport layer (TPBI) of 50 nm, a LiF layer of 0.8 nm and a metal aluminum layer of 100 nm were evaporated sequentially. Device performance is listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com