Manufacturing method of high-strength aluminum alloy welding connector

A welding joint and welding method technology, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve problems such as difficulty in meeting high strength, loss of strength of welded joints, and high sensitivity to thermal cracks. Effect of visible defects, well formed welds, high strength and joint coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: For 2mm thick Al-7.83Zn-2.87Mg-0.67Cu-0.50Mn-0.23Zr-

[0025] The 0.14Er hot-rolled and T6 state plates are fully automatic TIG wire-filled welding.

[0026] (1) Cut the plate into a size of about 105mm×100mm, and carry out chemical cleaning (70°C 8-10% NaOH solution → rinse with water → 30-40% HNO 3 solution → rinse with water → air dry), use a stainless steel wire brush to polish the butt joints of the plates before welding.

[0027] (2) The welding adopts a fully automatic TIG welding machine, the welding direction is perpendicular to the rolling direction of the base metal, the current type is sine wave AC, the diameter of the welding wire is 1.6mm, the diameter of the tungsten pole is 3mm, the distance between the tungsten pole and the base metal is 3mm, and the welding current is 125A , The welding speed is 27cm / min, the wire feeding speed is 40cm / min, the shielding gas is Ar, and the front and back gas flow rates are 20L / min and 10L / min respectively. ...

Embodiment 2

[0029] Embodiment 2: The metallographic structure analysis and mechanical performance test of the welded joint obtained in Example 1 were carried out.

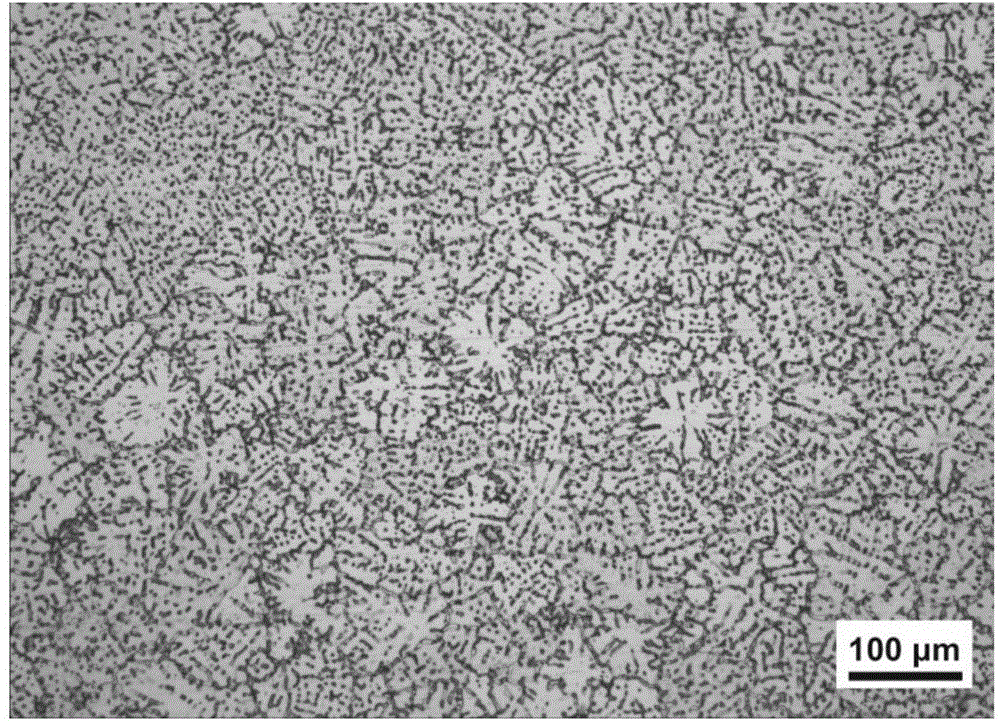

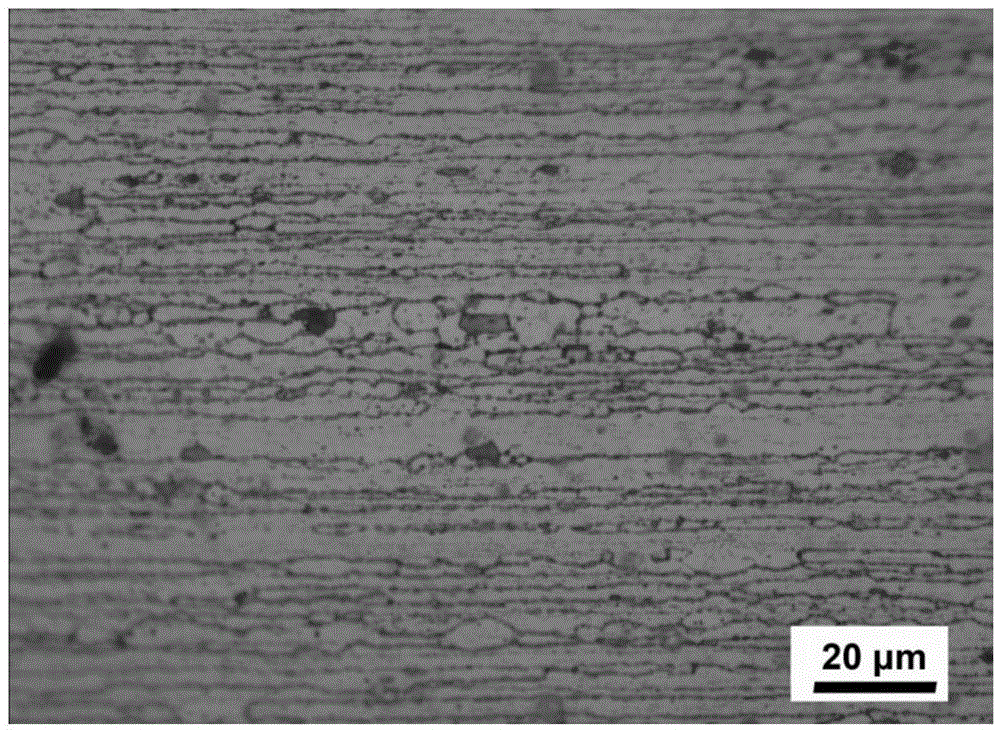

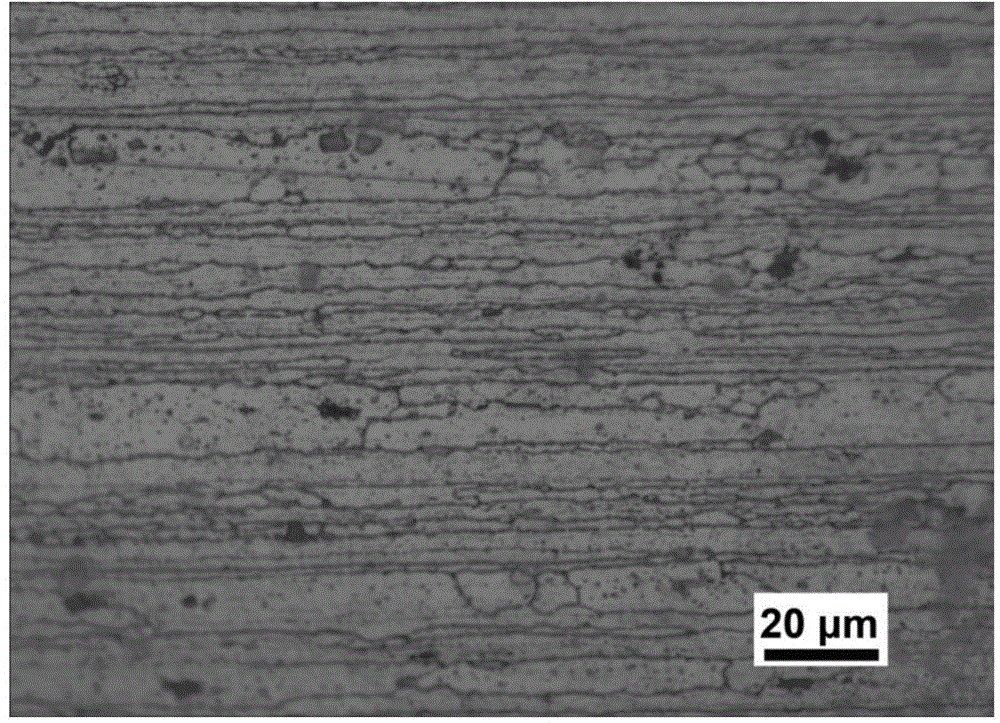

[0030] (1) For the welded joint of the T6 state base metal, the metallographic sample is taken perpendicular to the weld, and after mechanical grinding and polishing, the Keller reagent (1mlHF+1.5mlHCL+2.5mlHNO3+95mlH 2 O) and electrochemical corrosion method (electrolyte is 40mlH 3 PO 4 +38mlC 2 h 5 OH+20mlH 2 O) corrode the joint, and then observe the metallographic structure of each area of the joint under the OLYMPUS-BX51M metallographic microscope, figure 1 It is the metallographic structure of the weld area, and its shape is a small equiaxed dendrite with a grain size of about 40 μm. figure 2 , 3They are the grain morphology of the heat-affected zone and the base metal, respectively, both of which are elongated by rolling and partially recrystallized. The grain size is uneven, but there is no obvious grain growt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com