Selenium-rich germinated rough rice/asparagus fermented vinegar and preparation method thereof

A technology of selenium-enriched germinated brown rice and fermented vinegar, which is applied in the preparation of vinegar, biochemical equipment and methods, and methods based on microorganisms, can solve the problems of single ingredients and general taste, and achieve more nutrients and soft and refreshing taste , the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

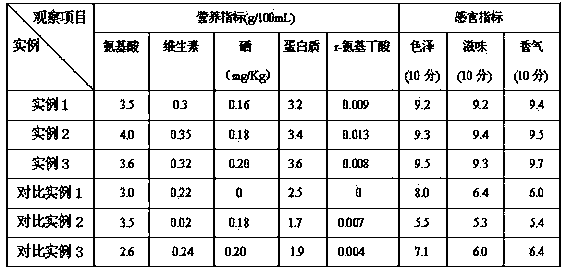

Examples

Embodiment 1

[0025] (1) Preparation of asparagus enzymatic hydrolysis solution: take 40kg of fresh and washed asparagus, cut into small pieces and refine it with a colloid mill, add 300kg of water to the slurry, mix and add according to the weight ratio (g / kg) of the raw material 0.70g / kg of pectinase with an enzyme activity of 6000U / g was enzymolyzed at 45°C for 14 hours to obtain an enzymatic hydrolyzate;

[0026] (2) Preparation of selenium-enriched spray solution: Take the pulverized selenium-enriched coal gangue with a diameter of 60 mesh, soak it in 20% (V / V) sulfurous acid solution for 20 hours, and use ultrasonic vibration to accelerate the dissolution of selenium; After soaking, add 5% (V / V) sodium phosphate solution to precipitate and filter the heavy metals in the selenium ore, add 8% (V / V) sodium hydroxide solution to the filtrate, and adjust the pH of the filtrate Adjusted to 6.5, the spray liquid is obtained;

[0027] (3) Preparation of selenium-enriched germinated brown ric...

Embodiment 2

[0033] (1) Preparation of asparagus enzymatic hydrolysis solution: Take 50kg of fresh and washed asparagus, cut into small pieces and use a colloid mill to refine the slurry, add 350kg of water to the slurry, mix and add according to the weight ratio (g / kg) of the raw materials 0.90 g / kg of pectinase with an enzyme activity of 6000 U / g was enzymolyzed at 50°C for 18 hours to obtain an enzymatic hydrolyzate;

[0034] (2) Preparation of selenium-enriched spray solution: Take the crushed selenium-enriched coal gangue with a diameter of 100 mesh, soak it in 30% (V / V) sulfurous acid solution for 50 hours, and use ultrasonic vibration to accelerate the dissolution of selenium; After soaking, add 10% (V / V) sodium phosphate solution to precipitate and filter the heavy metals in the selenium ore, add 13% (V / V) sodium hydroxide solution to the filtrate, and adjust the pH of the filtrate Adjusted to 8.5, the spray liquid is obtained;

[0035](3) Preparation of selenium-enriched germinat...

Embodiment 3

[0041] (1) Preparation of asparagus enzymatic hydrolysis solution: take 45kg of fresh and washed asparagus, cut it into small pieces and refine it with a colloid mill, add 325kg of water to the slurry, mix it and add it according to the weight ratio (g / kg) of the raw material 0.80g / kg of pectinase with an enzyme activity of 6000U / g was hydrolyzed at 47°C for 16 hours to obtain the hydrolyzate;

[0042] (2) Preparation of selenium-enriched spray solution: Take the crushed selenium-enriched coal gangue with a diameter of 80 mesh, soak it in 25% (V / V) sulfurous acid solution for 35 hours, and use ultrasonic vibration to accelerate the dissolution of selenium; After soaking, add 7% (V / V) sodium phosphate solution to precipitate and filter the heavy metals in the selenium ore, add 10% (V / V) sodium hydroxide solution to the filtrate, and adjust the pH of the filtrate Adjust to 7.5, that is, the spray liquid is prepared.

[0043] (3) Preparation of selenium-enriched germinated brown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com