High-heat-stability charring agent and preparation method thereof

A high thermal stability, carbon-forming agent technology, applied in the field of char-forming agents, can solve the problems of harsh reaction conditions, complicated purification process, and low thermal stability of products, and achieve low cost, high yield, and simple and easy preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048]The present invention also provides a preparation method of a high thermal stability char-forming agent, comprising the following steps:

[0049] (a), mix the cyanuric chloride, the acid-binding agent and the organic solvent accounting for 60-75% of the total volume together, drop the mixed solution formed by ethylenediamine and the remaining organic solvent, and keep the temperature of the reaction system at the same time 0-20℃;

[0050] (b) After adding the ethylenediamine dropwise, add the nitrogen-containing compound and react for 2-4 hours, raise the temperature of the reaction system to 40-70°C for 3-8 hours;

[0051] (c), then raising the temperature of the reaction system to 80-100° C. for 3-8 hours to obtain a reaction mixture;

[0052] (d) Suction-filtering the reaction mixture to obtain a solid, washing the solid with water until it is neutral, and then drying it.

[0053] The preparation method of the high thermal stability char forming agent provided by th...

Embodiment 1

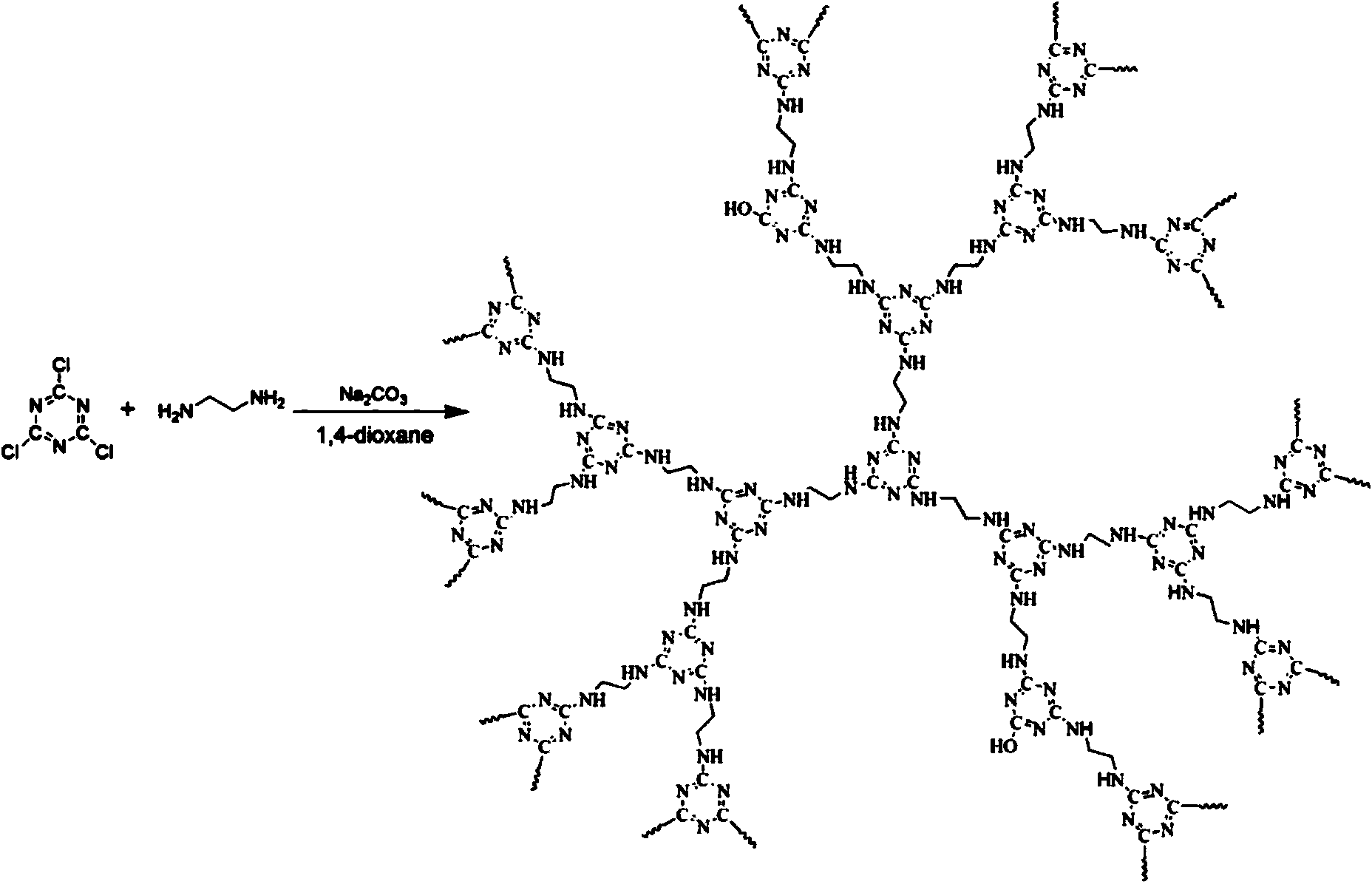

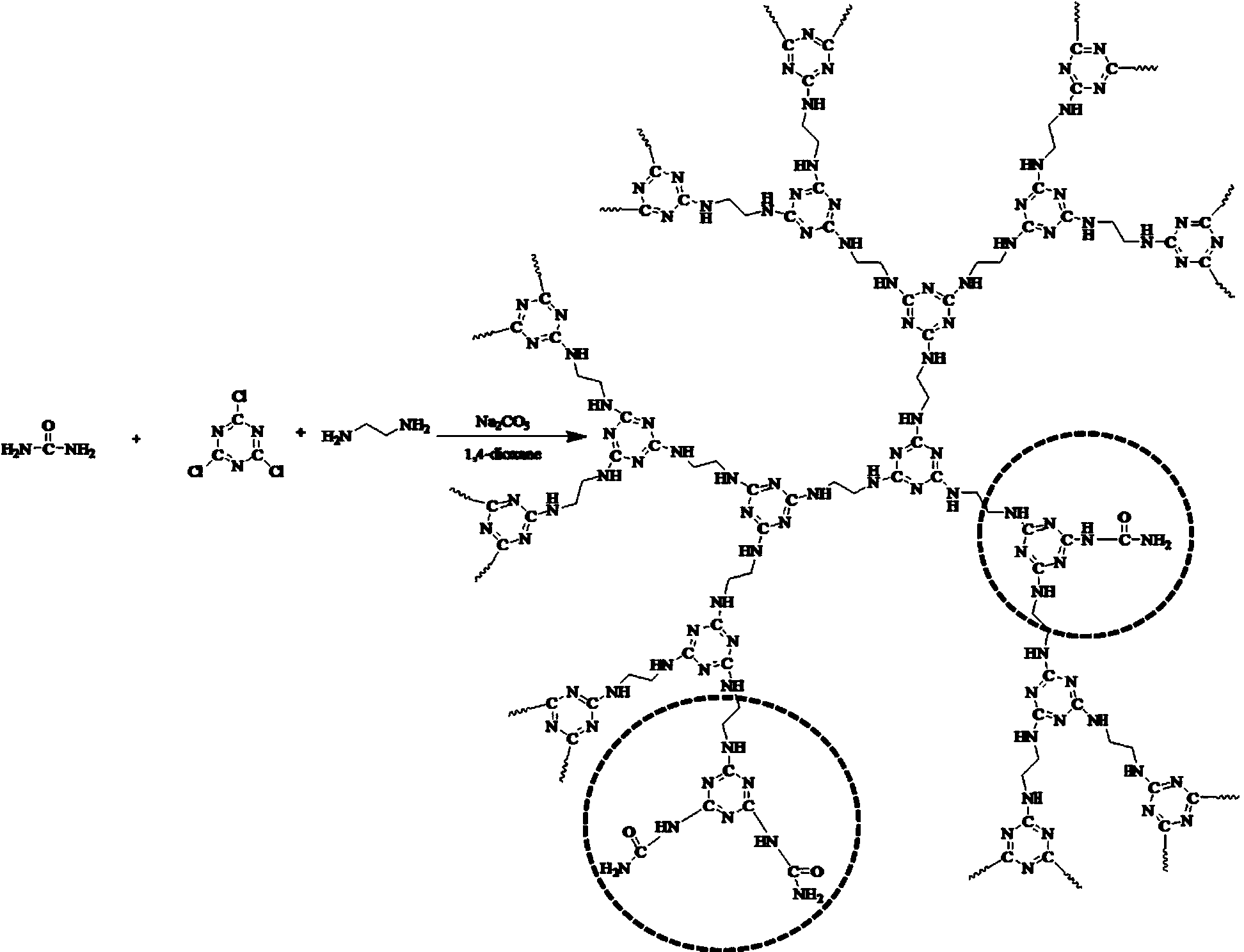

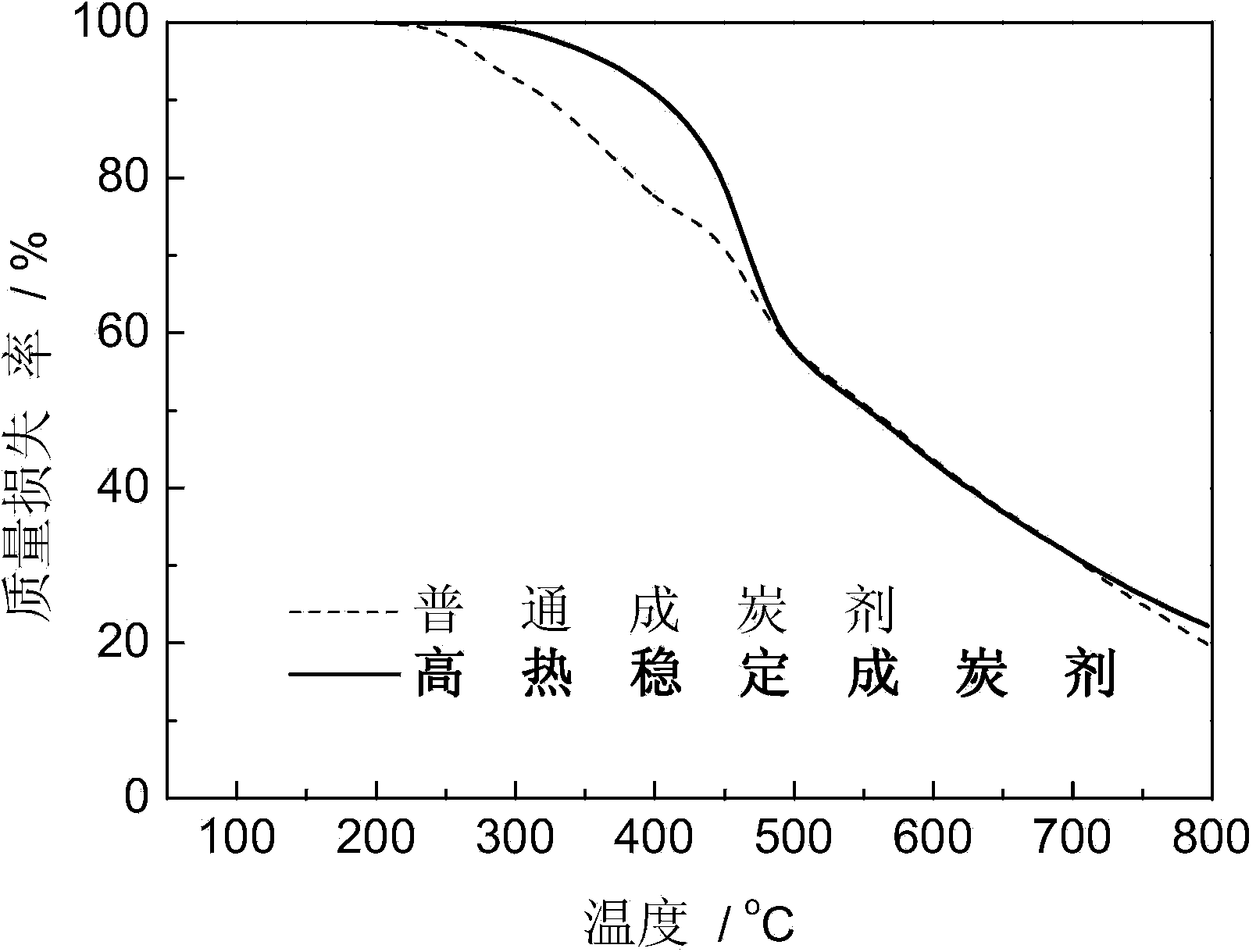

[0062] Add 55.92g of cyanuric chloride, 104.93g of anhydrous sodium carbonate and 450ml of dioxane in the three-necked flask, and after stirring evenly, add dropwise 150ml of dioxane solution of 22.72g of ethylenediamine in the reaction system at 0°C, After dripping, add 5.67g urea to react for 3h; raise the temperature of the reaction system to 50°C for 3h, then raise the temperature to 100°C for 3h; filter the reaction mixture, and wash the solid mixture in 100°C water until neutral. Then dry the product washed to neutral in an oven at 100°C to obtain the final product, the reaction formula is as follows figure 2 As shown, the yield is 99.9%, and the temperature at which the product decomposes 1% is 302°C. From figure 2 The structural formula and figure 1 It can be seen from the comparison of the structural formula (char-forming agent of the prior art) that the char-forming agent prepared by the present invention has significantly increased branch points and molecular ch...

Embodiment 2

[0064] Add 55.92g of cyanuric chloride, 119.11g of anhydrous sodium sulfite, and 364ml of acetonitrile into the three-necked flask, and after stirring evenly, add 24.14g of ethylenediamine in 242ml of acetonitrile solution dropwise to the reaction system at 7°C. After the dropwise addition, add 4.26g Urea was reacted for 2 hours; after the temperature of the reaction system was raised to 60°C for 4 hours, the temperature was raised to 80°C for 8 hours; The final product was dried in an oven at 120°C to obtain the final product with a yield of 99.8%, and the temperature at which the product decomposed 1% was 295°C. The structural formula of the char-forming agent prepared in this embodiment is consistent with the structural formula of the product in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com