Beneficiation method for copper-nickel sulfide ore containing layered silicate gangue easy to float

A technology of copper-nickel sulfide ore and beneficiation method, applied in flotation, solid separation, etc., can solve the problems of good natural buoyancy, high content of fine particle size, and large difference in buoyancy, so as to reduce the difficulty of flotation separation , improve quality and recovery rate, and have high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

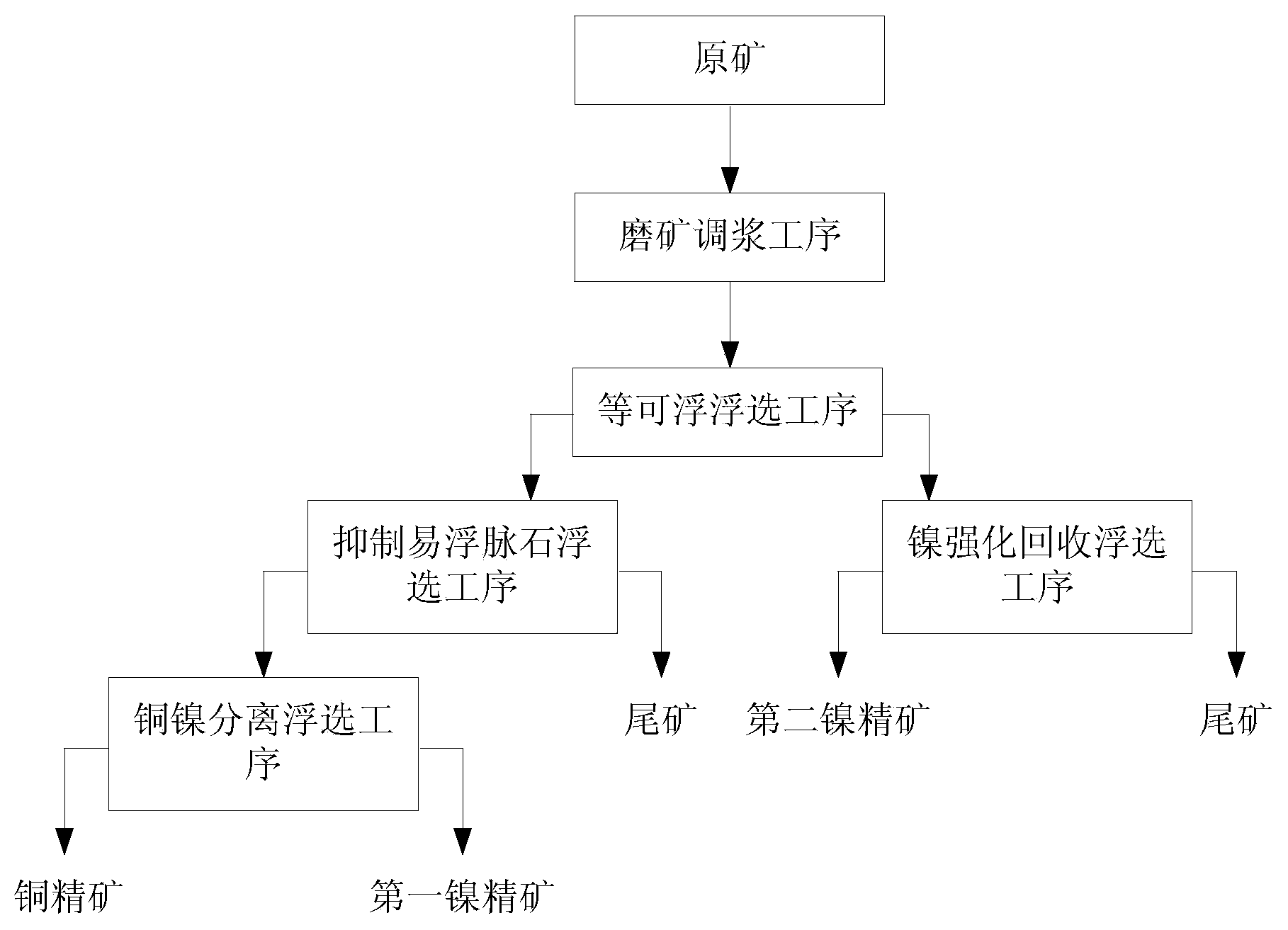

Method used

Image

Examples

Embodiment 1

[0051] In the raw ore of a deposit in Qinghai, the nickel content is 0.78% and the copper content is 0.16% by weight percentage. The metal minerals in the raw ore are mainly pyrrhotite; the copper minerals are mainly chalcopyrite and a small amount of chalcopyrite, chalcopyrite and copper blue; the nickel minerals are mainly pentlandite and a small amount of purple sulfur nickel ore; iron minerals are mainly magnetite and a small amount of limonite and siderite; other small amounts of sulfur are pyrite, and occasionally arsenite. The non-metallic minerals in the ore are mainly pyroxene and serpentine, followed by tremolite and chlorite, and a small amount of talc, olivine, albite, phlogopite and quartz.

[0052] Adopt the copper sulfide-nickel ore beneficiation method of the embodiment of the present invention one to carry out ore dressing to this raw ore, its concrete procedure is as follows:

[0053] (1) Grinding the raw ore until the ore with a particle size not greater th...

Embodiment 2

[0062] In the raw ore of a certain deposit in Xinjiang, the nickel content is 0.80% and the copper content is 0.20% by weight percentage. The metal minerals in the raw ore are mainly pyrrhotite; the copper minerals are mainly chalcopyrite and a small amount of chalcopyrite, chalcopyrite and copper blue; the nickel minerals are mainly pentlandite and a small amount of purple sulfur nickel ore, arsenic-nickel ore, arsenic-nickelite, cobalt-containing arsenic-nickelite, etc.; iron minerals are mainly magnetite and a small amount of limonite and siderite. The non-metallic minerals in the raw ore are mainly tremolite, talc and pyroxene, followed by serpentine, olivine, diopside, chlorite, actinolite, actinolite asbestos and serpentine asbestos, and There are a small amount of phlogopite, albite, quartz and calcite.

[0063] Adopt the copper-nickel sulfide ore beneficiation method of the embodiment of the present invention two to carry out ore dressing to this raw ore, and its conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com