Ammonium carbonate salt-based cane sugar juice clarifying, decolouring and decontaminating method

An ammonium carbonate, decolorization and impurity removal technology, applied in the purification of sugar juice, sucrose production, sugar production and other directions, can solve problems such as failure to popularize and apply, high cost, strong technicality, etc., and achieve mature production technology and utilization rate. High and simple effect of clarifying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

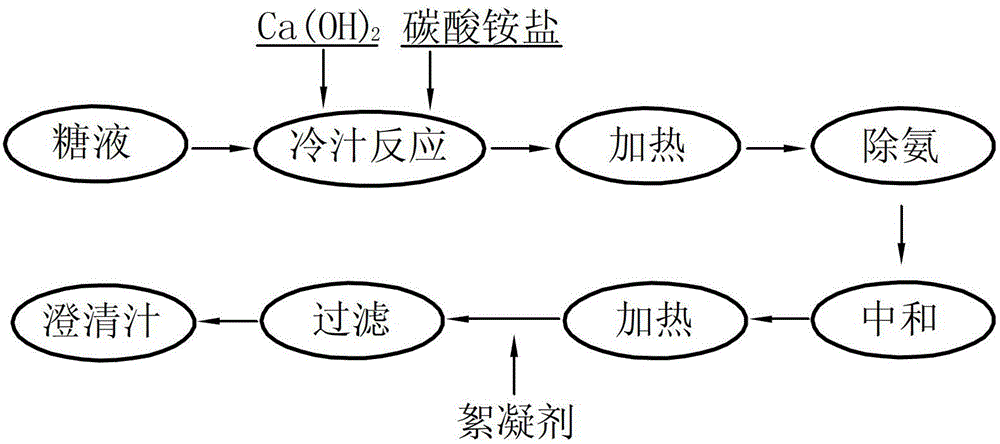

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: To the clarification, decolorization and impurity removal of brown granulated sugar back-dissolving solution.

[0023] Take 100mL of 15wt% brown sugar redissolution solution, add 9mL of calcium hydroxide emulsion with a mass concentration of 10% and 1.1 g of ammonium carbonate, fully mix and react for 15 minutes, and heat to 70°C for the first time to remove the ammonia generated by the reaction After degassing (the escaped ammonia can be absorbed by water), add an appropriate amount of phosphoric acid solution (the volume ratio of phosphoric acid to water is 1:1) to neutralize until the pH value reaches 7.0. Acrylamide flocculant 6ppm is used for flocculation and sedimentation. After the flocs are separated, sugar juice after clarification, decolorization and impurity removal is obtained, and the decolorization rate is 52.9%.

Embodiment 2

[0024] Example 2: Clarification, decolorization and impurity removal of sugarcane mixed juice.

[0025] Take 100mL of sugarcane mixed juice, add 10.33g of calcium oxide emulsion with a mass concentration of 10% and 1.1g of ammonium carbonate, mix and react for 20 minutes, then heat to 70°C to remove the ammonia gas generated by the reaction, then add an appropriate amount of phosphoric acid solution (phosphoric acid and The volume ratio of water is 1:1) to neutralize until the pH value reaches 7.0, and then raise the temperature to 100°C, add polyacrylamide flocculant 5ppm for flocculation and sedimentation, and after separating the flocs, the sugar juice after decolorization and impurity removal is obtained. The decolorization rate is 32.09%.

Embodiment 3

[0026] Embodiment 3: To the clarification, decolorization and impurity removal of brown granulated sugar back-dissolving solution.

[0027] Take 100mL of brown granulated sugar redissolution solution with a concentration of 15 wt%, add 7.15g of calcium oxide emulsion with a mass concentration of 10% and 0.8g of ammonium carbonate, mix and react for 15 minutes, heat to 70°C to remove the ammonia gas generated by the reaction , add an appropriate amount of phosphoric acid solution (the volume ratio of phosphoric acid to water is 1:1) to neutralize until the pH value reaches 7.0, continue to heat up to 100°C, add polyacrylamide flocculant 4ppm for flocculation and sedimentation, and separate the flocs to obtain clarification The sugar juice after decolorization and impurity removal has a decolorization rate of 49.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com