Method for treating glyphosate waste water by using calcium hypochlorite waste water

A glyphosate wastewater and wastewater treatment technology, applied in the chemical industry, can solve the problems of high cost and complicated process, and achieve the effect of low cost, good treatment effect and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

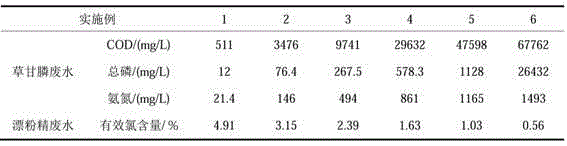

Embodiment 1

[0020] Add 5 parts of bleaching powder wastewater to a reactor containing 100 parts of glyphosate waste water in 0.2h under stirring at 25°C, continue to stir for 1h to make the two evenly mixed; then adjust the reaction temperature in the reactor Increase to 50°C and continue to stir and react for 6 hours to obtain a pretreatment liquid; add 0.14 parts of NaOH to the reactor containing the pretreatment liquid, cool and filter to obtain a colorless and transparent liquid with pH=8; then add 3.5 parts of anhydrous carbonic acid Sodium was added to the obtained filtrate under stirring at room temperature, and white calcium carbonate precipitate and colorless filtrate were obtained after filtration. The pH of the filtrate was adjusted to 7-9 with hydrochloric acid, and the filtrate was distilled to crystallize sodium chloride. The final liquid COD, TP, ammonia nitrogen and salt content were not detected.

Embodiment 2

[0022] Add 35 parts of bleaching powder wastewater to a reactor containing 100 parts of glyphosate wastewater in batches within 3 hours under stirring at 25°C, continue to stir for 1 hour to mix the two uniformly; then increase the reaction temperature in the reactor Continue to stir and react at 70°C for 4 hours to obtain a pretreatment liquid. Combine 0.8 parts of NaOH and Ca(OH) 2 The mixture is added to the reactor containing the pretreatment liquid, in which NaOH and Ca(OH) 2 The mass ratio is 2:1. After cooling and filtering, a colorless and transparent liquid with pH=9 is obtained; then 5.2 parts of anhydrous sodium carbonate are added to the filtrate under stirring at room temperature, and a white calcium carbonate precipitate and a colorless filtrate are obtained after filtration. , Adjust the pH value of the filtrate to 7-9 with hydrochloric acid, and distill the filtrate to crystallize sodium chloride. The final liquid COD, TP, ammonia nitrogen and salt content were ...

Embodiment 3

[0024] Add 105 parts of bleaching powder wastewater into a reactor containing 100 parts of glyphosate wastewater by continuous dripping within 4 hours under stirring at 50°C to mix the two evenly, and then continue to stir and react for 5 hours at a constant temperature to obtain Pretreatment liquid. 2.42 parts Ca(OH) 2 Add to the reactor equipped with pretreatment liquid, cool and filter to obtain a colorless and transparent liquid with pH=9; then add 8.6 parts of anhydrous sodium carbonate to the filtrate obtained under stirring at room temperature, and obtain white calcium carbonate precipitate and Colorless filtrate, adjust the pH value of the filtrate to 7-9 with hydrochloric acid, and distill the filtrate to crystallize sodium chloride. The final liquid COD, TP, ammonia nitrogen and salt content were not detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com