Treatment technique of manganese-containing wastewater in wet electrolytic manganese production process

A production process and treatment process technology, applied in the field of manganese-containing wastewater treatment process, can solve the problems of complex water quality, difficult operation and use, etc., achieve the effect of no secondary pollution, realize circular economy, and eliminate environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

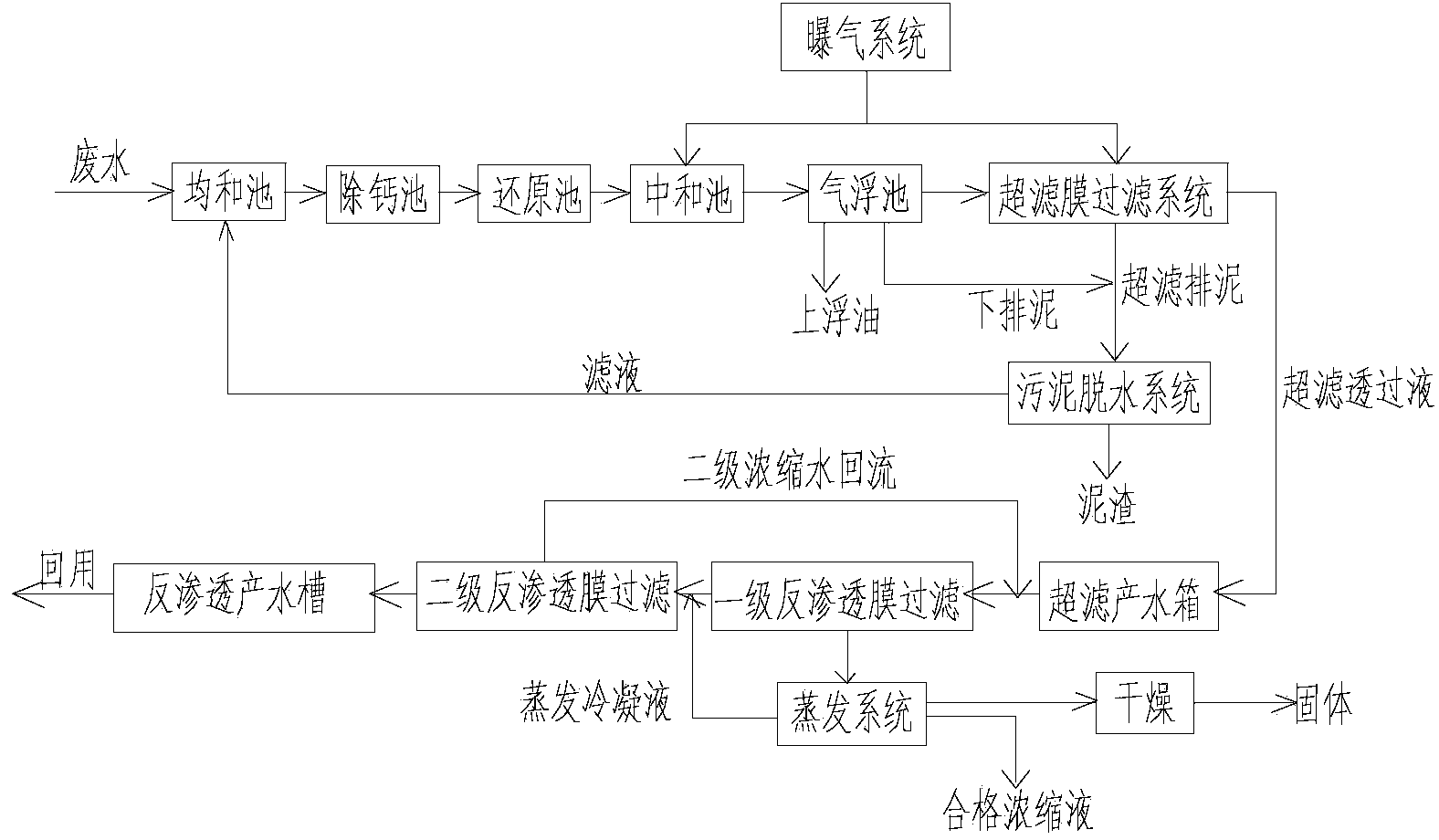

[0080] The ammonium- and manganese-containing waste water in the electrolytic manganese production process is taken as the raw water to be treated. The quality of the raw water is shown in Table 1. The system process is as follows: figure 1 shown.

[0081] Table 1

[0082] project

unit

value

pH

4~5

NH 4 +

mg / L

1400

mn 2+

mg / L

1500

Ca 2+

mg / L

650

Cr 6+

mg / L

4.5

TDS

mg / L

14000

oil

mg / L

0.5

SS

mg / L

65

[0083] project

unit

value

TOC

mg / L

<15

[0084] The raw water of wastewater enters the equalization tank first, and the water quality and quantity are balanced, and the wastewater flow rate is controlled to 100m 3 / h, residence time 8h.

[0085] Use the lift pump to transport the effluent from the homogenization tank to the decalcification tank, add decalcifier oxalic acid, let the calc...

Embodiment 2

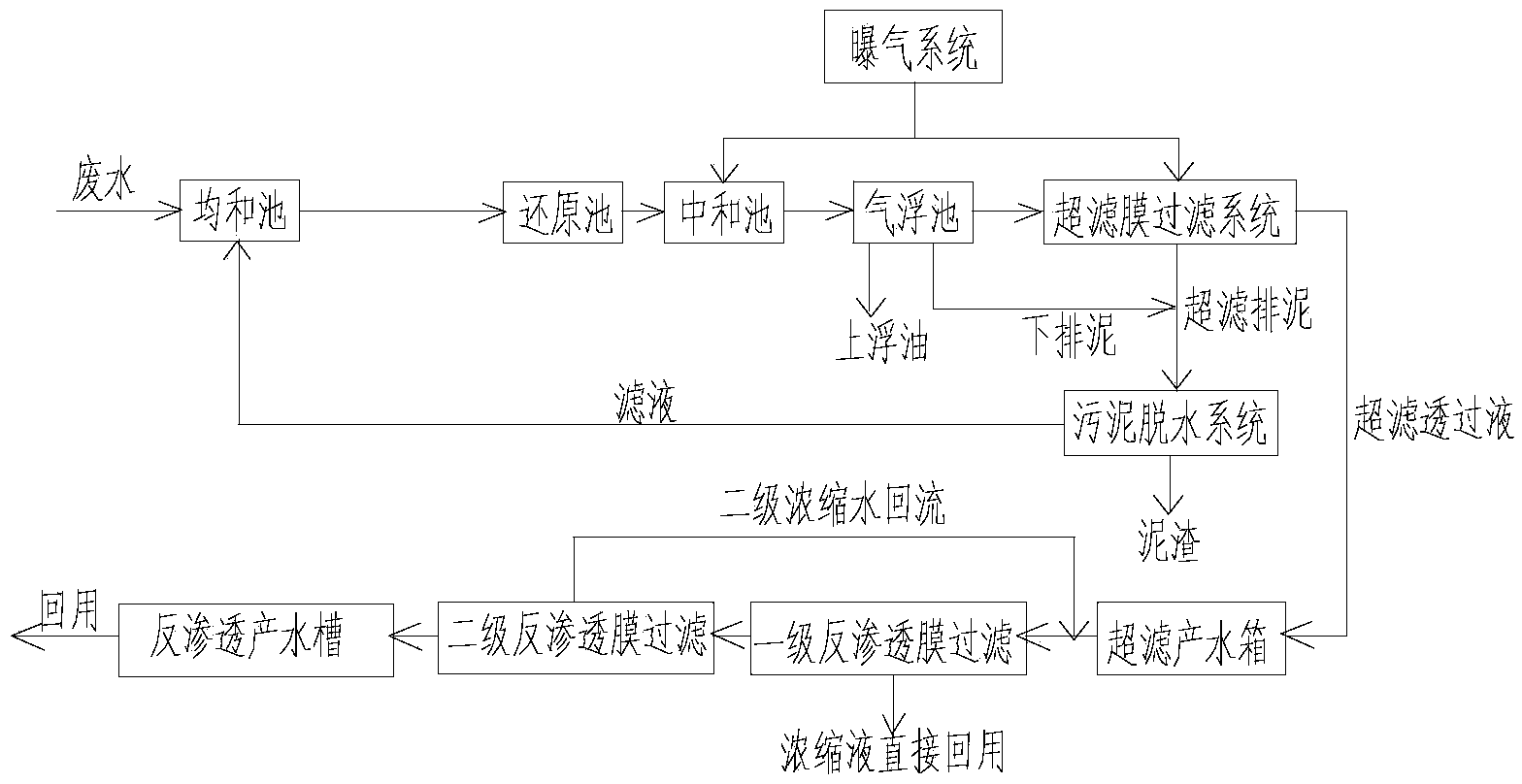

[0097] The specifications of raw water to be treated are shown in Table 3, and the process flow is as follows figure 2 Shown, main steps are the same as embodiment 1, just reduced decalcification step. In addition, the RO concentrate is recycled to the electrolysis production process.

[0098] table 3

[0099] project

unit

value

pH

6.5

NH 4 +

mg / L

1900

mn 2+

mg / L

1800

Ca 2+

mg / L

150

Cr 6+

mg / L

1.5

TDS

mg / L

18000

oil

mg / L

0.5

SS

mg / L

80

TOC

mg / L

<15

[0100] The raw water of wastewater enters the equalization tank first, and the water quality and quantity are balanced, and the wastewater flow rate is controlled to 100m 3 / h, residence time 8h.

[0101] Pump the effluent from the equalization tank into the reduction tank, add sulfuric acid to adjust the pH of the wastewater to 4, then add the reducing agent ...

Embodiment 3

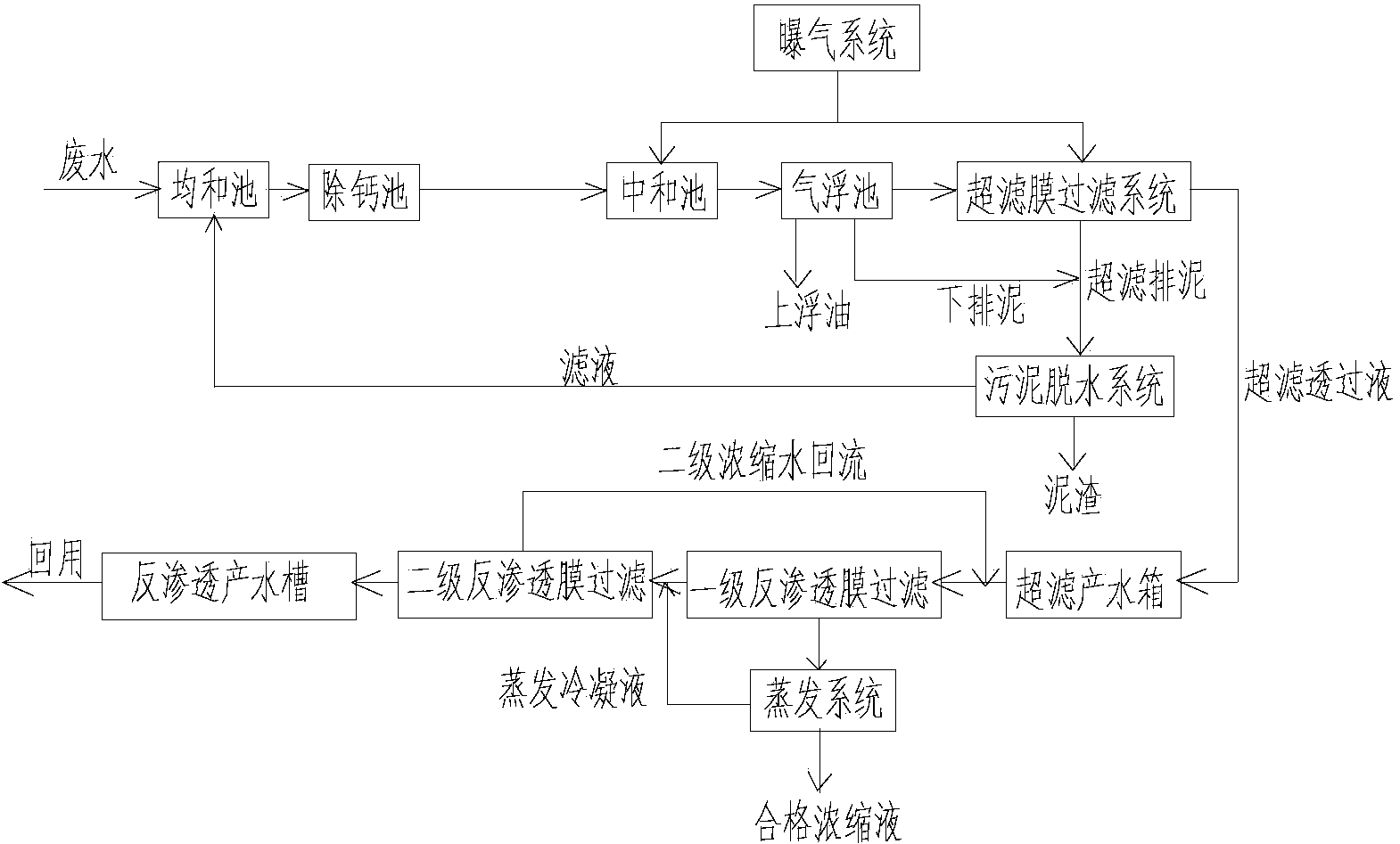

[0112] The specifications of raw water are shown in Table 5, and the process flow is as follows image 3 As shown, the main steps are the same as in Example 1, and the reduction steps are reduced because the water body does not contain chromium.

[0113] table 5

[0114] project

unit

value

pH

6.5

NH 4 +

mg / L

1700

mn 2+

mg / L

1900

Ca 2+

mg / L

450

TDS

mg / L

17000

oil

mg / L

0.3

SS

mg / L

65

TOC

mg / l

<15

[0115] The raw waste water first enters the equalization tank to balance the water quality and quantity, and control the waste water flow to 50m 3 / h, residence time 8h.

[0116] Use a lift pump to transport the effluent from the homogenization tank to the decalcification tank, add decalcifier oxalic acid, let the calcium ions in the wastewater react with oxalic acid to form calcium oxalate solids, and keep the calcium ion concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com