Glass-fiber reinforced molded plastic of heat-resistant environment-friendly phenolic resin

An environmentally friendly phenolic resin and reinforced mold technology, which is applied in the field of glass fiber reinforced molding plastics, can solve the problems of low labor efficiency and high energy consumption, and achieve the effects of clear proportioning, low heat distortion temperature, and huge economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

[0015] A heat-resistant environmental protection phenolic resin glass fiber reinforced molding compound, characterized in that it includes the following components,

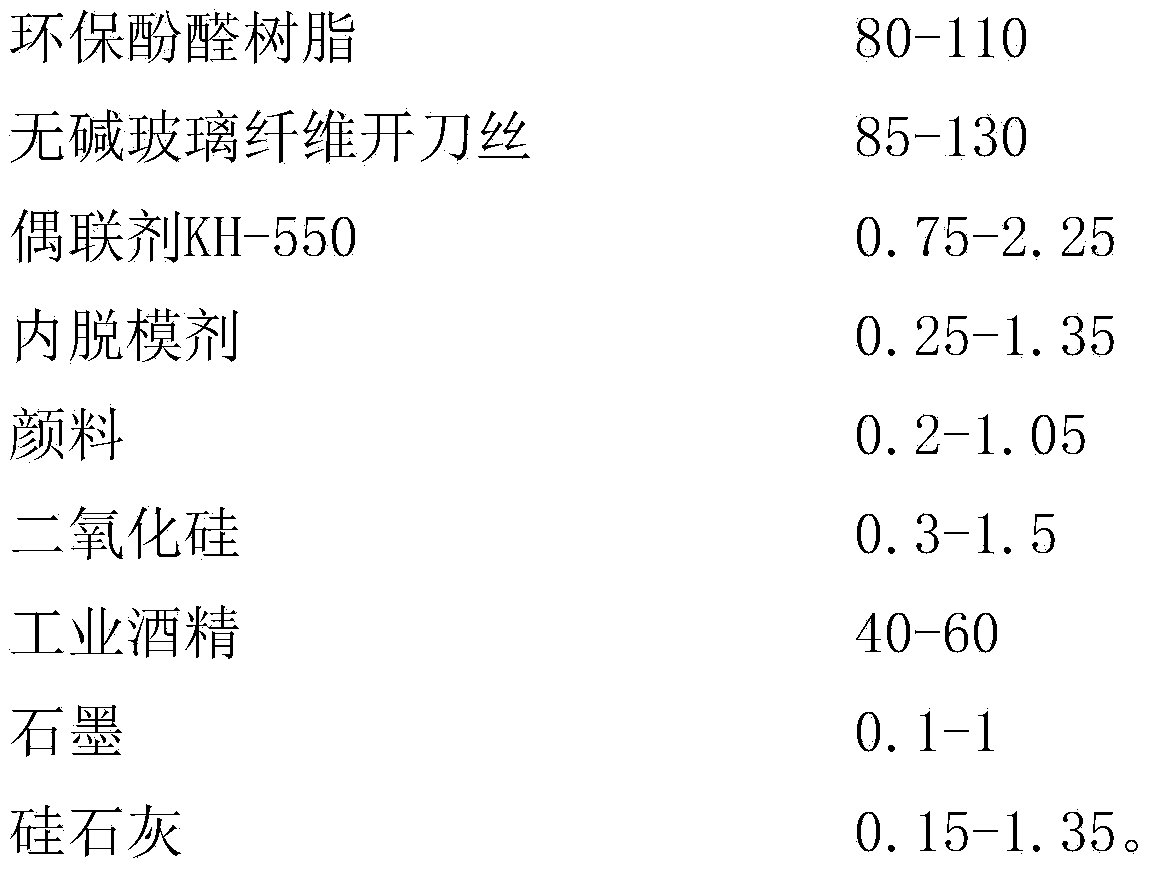

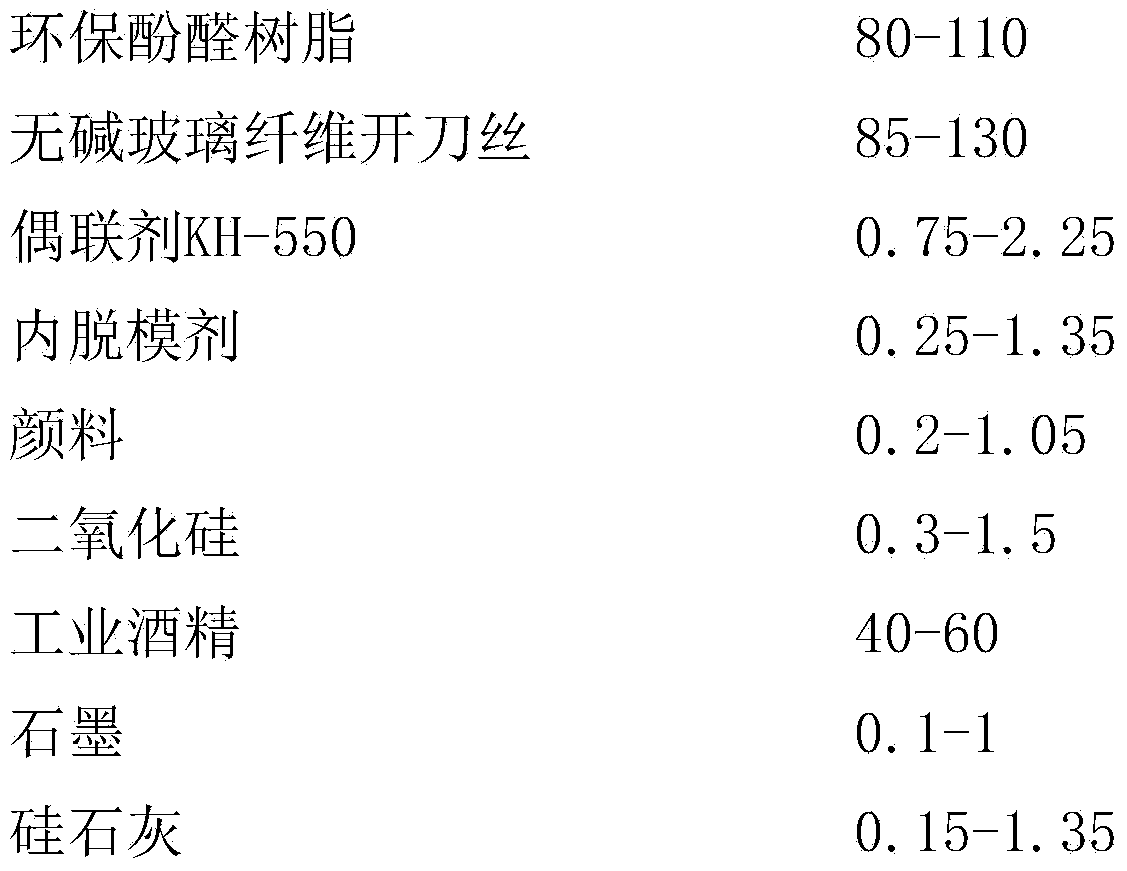

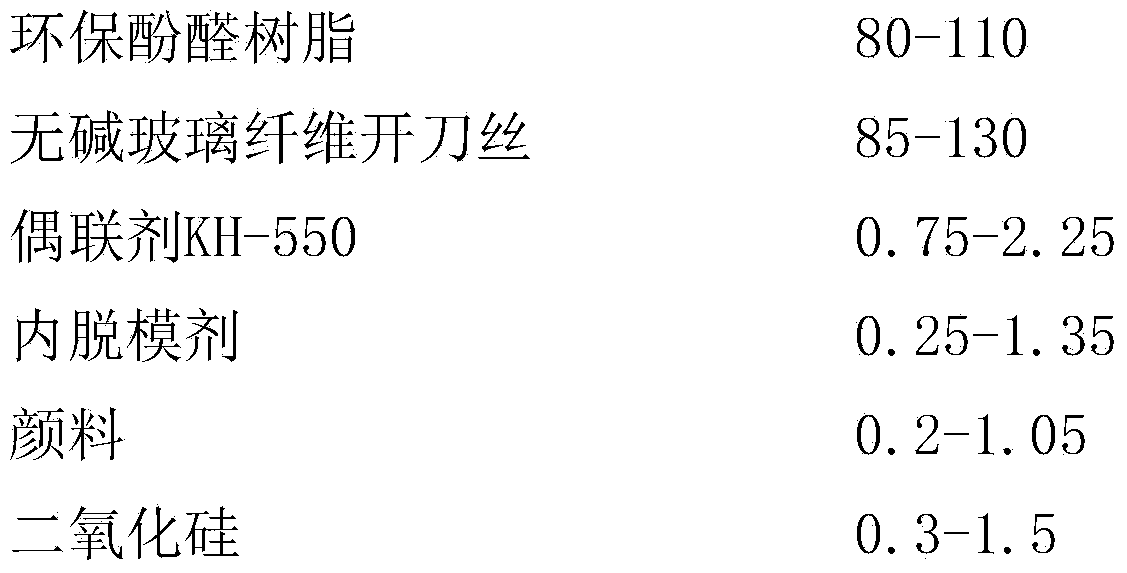

[0016] The distribution ratio of each group is as follows in weight fraction,

[0017]

[0018]

[0019] The internal release agent is oleic acid;

[0020] A method for preparing a heat-resistant environment-friendly phenolic resin glass fiber reinforced molding compound, comprising the following steps,

[0021] Step 1. Synthesis of environmentally friendly phenolic resin: phenol: aniline: solid formaldehyde = 1:0.1~0.2:1.2~1.8mol ratio, the operation steps are as follows: melt 80~120g of phenol, add 1~5g of magnesium oxide, and stir for 20min , then add 1-10g of aniline, and finally add 20-120g of solid forma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com