A kind of method utilizing screw machine to prepare biodiesel

A biodiesel, screw machine technology, applied in biofuel, petroleum industry, fatty acid production and other directions, can solve the problems of easy aging of catalysts, low space velocity reaction, high reaction temperature, improve aging resistance, reduce reaction temperature, and improve reaction The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

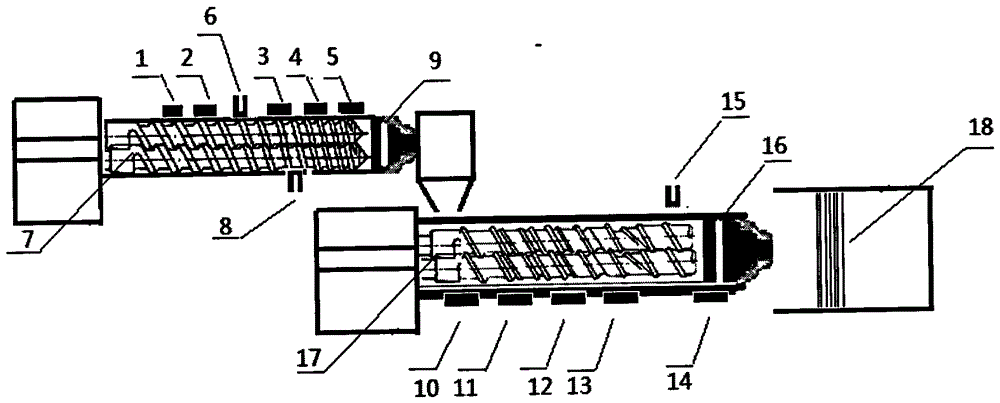

Method used

Image

Examples

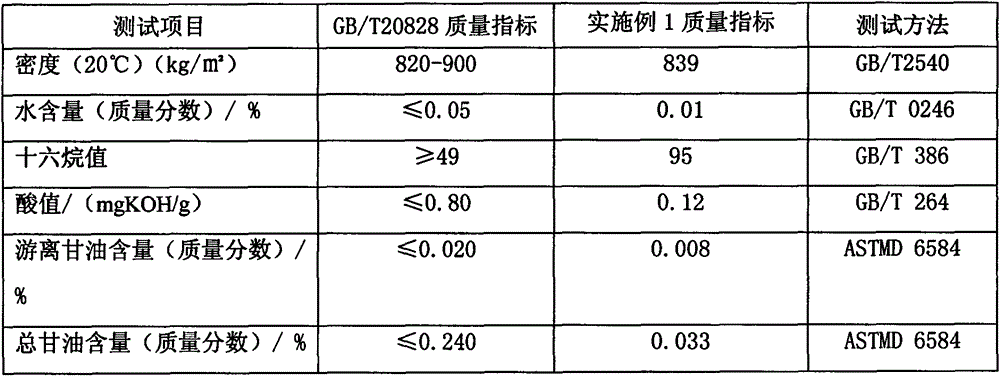

Embodiment 1

[0044] 1) Inject rapeseed oil into the preheated two-stage twin-screw machine with the first stage co-meshing, the screw length-to-diameter ratio is 30, the screw diameter is 35mm, and the temperature settings of each reaction section are 80-100°C, 100- 120°C, 100-110°C, 100-90°C, 90-80°C, the first-stage screw head pressure is 1MPa, the host speed is 200 rpm, and vacuum devolatilization is set between the second and third stage heating to exclude The water in the grease, the hydrogen pump is installed in the third and fourth stage heating, and the hydrogen is pumped in. The head is equipped with a porous plate made of tungsten oxide loaded on bauxite and sintered by bauxite. Through the dispersion and constant pressure of the first stage screw machine, the Grease and hydrogen form a homogeneous reaction interface, and quickly catalyze hydrogenation;

[0045] 2) After catalytic hydrogenation of the first-stage screw, it enters the second-stage co-meshing of the two-stage screw...

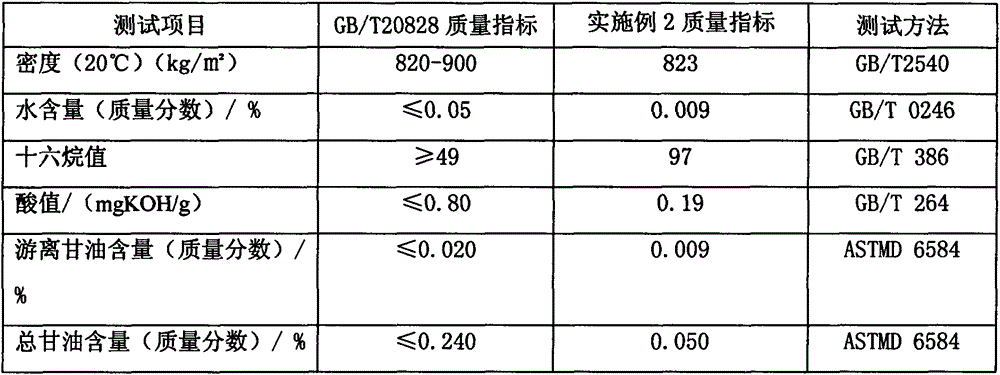

Embodiment 2

[0050] 1) Inject soybean oil into the first stage of the preheated two-stage twin-screw machine, the screw length-to-diameter ratio is 25, the screw diameter is 40mm, and the temperature settings of each reaction section are 80-100°C, 100-120°C ℃, 100-110℃, 100-90℃, 90-80℃, the pressure of the first-stage screw head is 2MPa, the speed of the main engine is 28 rpm, and vacuum devolatilization is set between the second and third heating stages to remove grease The moisture in the medium is installed in the third and fourth stage heating room, and the hydrogen is pumped in. The head is equipped with a porous plate made of nickel phosphide loaded on bauxite and sintered by bauxite. Through the dispersion and constant pressure of the first stage screw machine, the Grease and hydrogen form a homogeneous reaction interface, and quickly catalyze hydrogenation;

[0051] 2) After the catalytic hydrogenation of the first-stage screw, it enters the second-stage counter-meshing of the doub...

Embodiment 3

[0056]1) Inject the grease recovered from the kitchen into the first-stage counter-meshing of the preheated two-stage twin-screw machine. The length-to-diameter ratio of the screw is 40, and the diameter of the screw is 45mm. The temperature settings of each reaction section are 80-100°C, 100°C -120°C, 100-110°C, 100-90°C, 90-80°C, the first-stage screw head pressure is 2MPa, the host speed is 300 rpm, vacuum devolatilization is set between the second and third stage heating, Remove the moisture in the grease, install a hydrogen pump between the third and fourth stage heating, pump in the hydrogen, and set the porous plate made of copper oxide loaded on the bauxite sintered in the head, through the dispersion and constant pressure of the first stage screw machine, Make oil and hydrogen form a homogeneous reaction interface, and quickly catalyze hydrogenation;

[0057] 2) After the catalytic hydrogenation of the first-stage screw, it enters the second-stage co-meshing of the do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com