Preparation method of graphene-based composite membrane

A graphene composite and graphene technology, applied in the field of continuous preparation of composite membranes, can solve the problems of difficulty in large-scale preparation and application of graphene composite membranes, complex preparation methods, poor controllability of membrane structures, etc., and achieve low cost , Wide range of raw material sources and many types of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

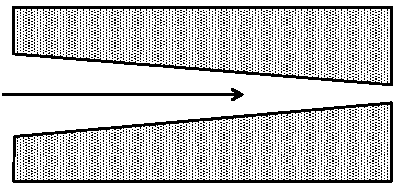

Method used

Image

Examples

Embodiment 1

[0032] (1) 1 part by weight of graphene oxide, 1 part by weight of sodium alginate, and 20 parts by weight of deionized water were ultrasonically treated at 75° C. for 6 hours at 30 KHz to obtain a graphene oxide / sodium alginate mixture.

[0033] (2) Extrude the graphene oxide / sodium alginate mixture at an extrusion speed of 10 mL / h in a preparation device with a straight die, and put it in an aqueous solution of potassium chloride and sodium chloride at 20°C ( The mass fractions of sodium chloride and potassium chloride are both 2.5%) and stay for 20s to solidify to form a film, and a graphene oxide / sodium alginate composite film is obtained.

[0034] (2) The graphene oxide / sodium alginate membrane obtained in step (1) was placed in hydrazine hydrate with a mass fraction of 20% for reduction for 2 hours, washed and dried to obtain a graphene / sodium alginate composite membrane.

[0035] Through the above steps, a graphene / sodium alginate composite film with a width of 150 mm a...

Embodiment 2

[0038] (1) 1 part by weight of graphene, 0.1 part by weight of polyethersulfone, and 20 parts by weight of N-methylpyrrolidone were ultrasonically treated at 100° C. for 3 hours at 50 KHz to obtain a graphene / polyethersulfone mixture.

[0039] (2) Extrude the graphene / polyethersulfone mixture at a speed of 100 mL / h in a preparation device with a straight die, and put it in a methanol solution of sodium hydroxide (10% by mass fraction) at 20°C ) for 20s to solidify into a film, and a graphene / polyethersulfone composite film was obtained after drying.

[0040] Through the above steps, a graphene / polyethersulfone composite membrane with a width of 200 mm and a thickness of 200 microns was prepared. The prepared composite film not only has the conductivity of graphene (10000S / m), but also has the elasticity of polyethersulfone polymer, and the elongation at break reaches 10%, which can be used as an antistatic film. At the same time, this composite film bubble has no obvious defo...

Embodiment 3

[0042] (1) 1 part by weight of graphene oxide, 0.01 part by weight of polystyrene, and 50 parts by weight of tetrahydrofuran were ultrasonically treated at 30° C. for 1 hour at 20 KHz to obtain a graphene oxide / polystyrene mixture.

[0043] (2) Extrude the graphene oxide / polystyrene mixture at an extrusion speed of 30 mL / h in a preparation device with a straight die, and put it in an aqueous solution of calcium chloride and sodium chloride (chloride) at 20 °C. The mass fractions of calcium chloride and sodium chloride are both 5%) to solidify into a film for 10 seconds, and a graphene oxide / polystyrene composite film is obtained after drying.

[0044] (3) Put the graphene oxide / polystyrene composite film in 20% sodium thiosulfate aqueous solution for reduction for 2 hours, wash and dry to obtain the graphene / polystyrene composite film.

[0045] After the above steps, a graphene / polystyrene composite film with a width of 300 mm and a thickness of 50 microns is prepared. The str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com