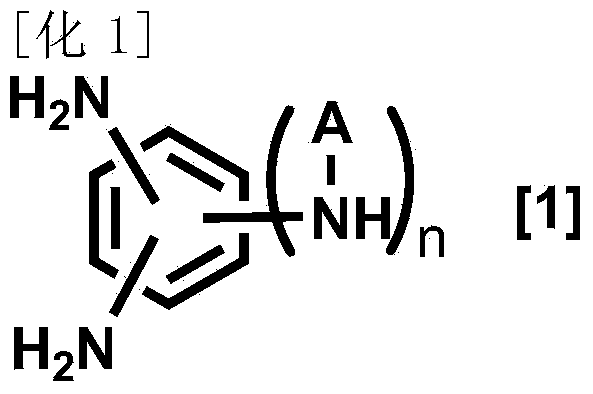

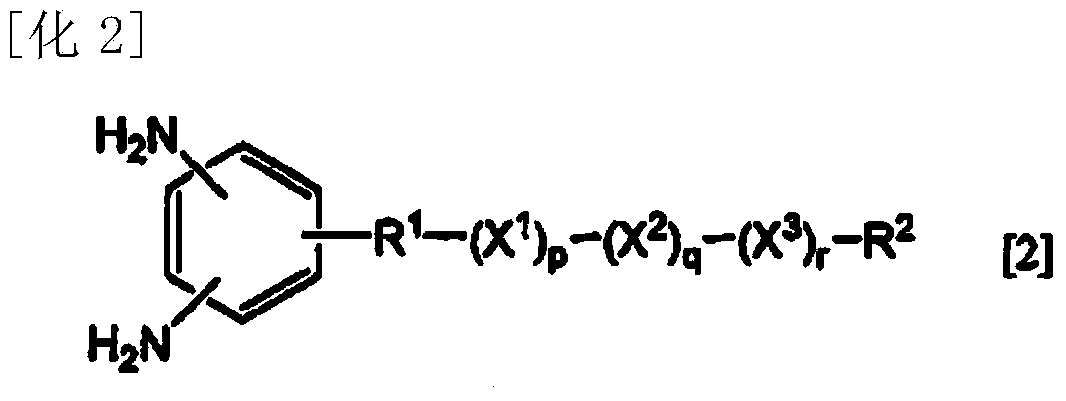

Novel diamine, polymer, liquid crystal alignment agent, and liquid crystal alignment film, and liquid crystal display element using same

A technology of liquid crystal alignment film and liquid crystal alignment agent, which is applied in the direction of instruments, optics, nonlinear optics, etc., can solve the problems of decreased liquid crystal orientation and easy accumulation of RDC, and achieve excellent abrasion resistance, good orientation of liquid crystal, Good solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

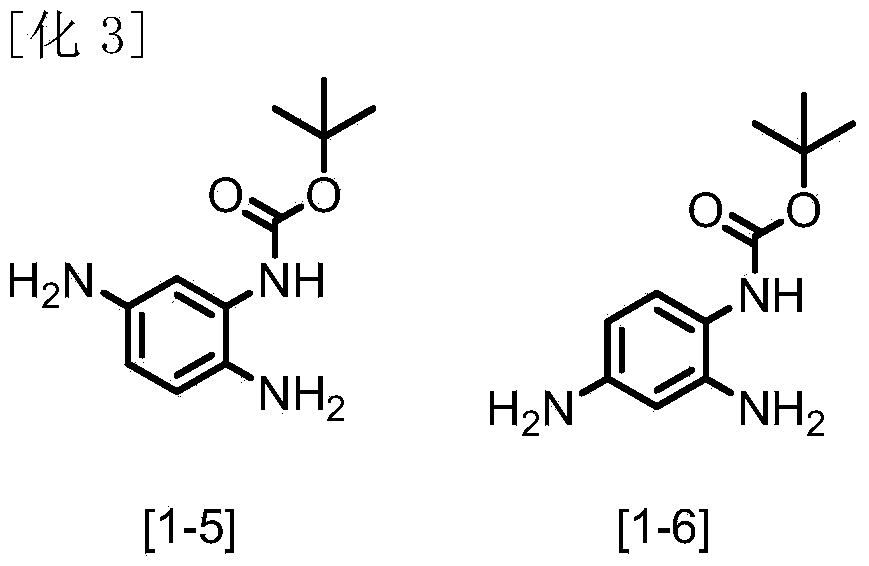

[0255] Synthesis of 2,5-diaminotert-butoxycarbonylaminobenzene[B-7]

[0256]

[0257] The first step of synthesis of 4-nitro 2-tert-butoxycarbonylaminoaniline

[0258] Measure 50.0g (326.5mmol) of 4-nitro-1,2-phenylenediamine in a 1L four-neck flask, add 500ml of THF and dissolve it, heat to about 60°C under a nitrogen atmosphere, use a drop 71.3 g (326.5 mmol) of tert-butyl dicarbonate was slowly dropped over a period of time through the funnel, and refluxed for 4 hours.

[0259] After the reaction, the reaction solution was concentrated with a rotary evaporator, and recrystallized in a mixed solvent of ethyl acetate:n-hexane (volume ratio 7:3) to obtain 62.0 g of an orange solid (yield 75%).

[0260] Synthesis of the second step [B-7]

[0261] In a four-necked flask of 1L, measure 60.0g (236.9mmol) of 2-tert-butoxycarbonylamino-5-nitroaniline, 6.0g of 10wt% palladium carbon, add 500ml of THF, and carry out decompression degassing and Hydrogen substitution, reaction at ...

Embodiment 2

[0265] Synthesis of 2,4-diamino-2-tert-butoxycarbonylaminobenzene[B-8]

[0266]

[0267] The first step of synthesis of 2,4-dinitro-tert-butoxycarbonylaminobenzene

[0268] Measure 22.8g (about 273.0mmol) of sodium hydride (purity: 50%) in a 1L four-necked flask, add 500ml of DMF, cool to about 0°C under a nitrogen atmosphere, and slowly drop 50.0g (273.0mmol) A DMF solution of 2,4-dinitroaniline was reacted for 1 hour, 59.6 g (273.0 mmol) of tert-butyl dicarbonate was slowly dropped over 1 hour using a dropping funnel, and reacted at room temperature for 2 hours.

[0269] After the reaction is over, add 500ml of ion-exchanged water and stir immediately to precipitate a solid. The solid is recovered by filtration, washed several times with methanol, and carried out in a mixed solvent of ethyl acetate and n-hexane (volume ratio 5:5). Recrystallization gave 60.3 g of a pale yellow solid (yield 78%).

[0270] Synthesis of the second step [B-8]

[0271] In a 1L four-necked fla...

Embodiment 3

[0275] Polymerization of polyamic acid [PAA-1:A-1 / B-7] and preparation of alignment agent [AL-1]

[0276] In a 50ml four-necked flask with a nitrogen inlet tube and a mechanical stirrer, measure 3.35g (15.00mmol) of B-7, add 34.8g of NMP and dissolve, cool to about 10°C under a nitrogen atmosphere, and gradually 2.85 g (14.60 mmol) of A-1 was added, and it returned to room temperature and was reacted for 6 hours to obtain a 15% by mass polyamic acid solution [PAA-1].

[0277] The number average molecular weight of the obtained PAA-1 was 11300, and the weight average molecular weight was 24500.

[0278] Measure 10.0 g of this polyamic acid solution in a 50 ml Erlenmeyer flask with a stirrer, add 7.5 g of NMP, 7.5 g of BCS, and stir at room temperature for 30 minutes to obtain 6.0 mass % of PAA-1 and 6.0 mass % of NMP. Alignment agent [AL-1] of 64 mass % and 30 mass % of BCS.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com