Hydrotalcite/cuprous oxide nanocomposite material and application thereof

A nano-composite material and cuprous oxide technology, applied in the field of water treatment, can solve the problems of increased cost, secondary pollution, complicated operation process, etc., and achieve the effects of low cost, convenient operation and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 Preparation of hydrotalcite / cuprous oxide nanocomposite

[0043] Take 20mL 0.2mol / L copper acetate in a conical flask according to the molar ratio of copper acetate and sodium thiosulfate as 1:1.5, slowly add 15mL 0.4mol / L sodium thiosulfate solution, add 0.57g hydrotalcite and stir After 20 minutes, add 0.11g of glucose and stir, slowly add 15mL of 0.4mol / L sodium hydroxide solution under ultrasonic conditions, the temperature is 30-50°C, ultrasonic for 20min, centrifuge, wash, and dry at 50°C to obtain hydrotalcite / suboxide copper nanocomposites.

Embodiment 2

[0045] Take 100mL 0.225mol / L copper acetate in a conical flask according to the molar ratio of copper acetate and sodium thiosulfate as 1:1.75, slowly add 88mL 0.45mol / L sodium thiosulfate solution, add 4.0g hydrotalcite and stir After 25 minutes, add 0.77g of glucose and stir, slowly add 87mL of 0.45mol / L sodium hydroxide solution under ultrasonic conditions, the temperature is 30-50°C, ultrasonic for 25min, centrifuge, wash, and dry at 55°C to obtain hydrotalcite / suboxide copper nanocomposites.

Embodiment 3

[0047] Take 200mL 0.25mol / L copper acetate in a Erlenmeyer flask according to the molar ratio of copper acetate and sodium thiosulfate as 1:2, slowly add 200mL 0.5mol / L sodium thiosulfate solution, add 10.0g hydrotalcite and stir 30min, then add 2g of glucose and stir, slowly add 200mL of 0.5mol / L sodium hydroxide solution under ultrasonic conditions, the temperature is 30-50°C, ultrasonic for 30min, centrifuge, wash, and dry at 55°C to obtain hydrotalcite / cuprous oxide nanocomposites.

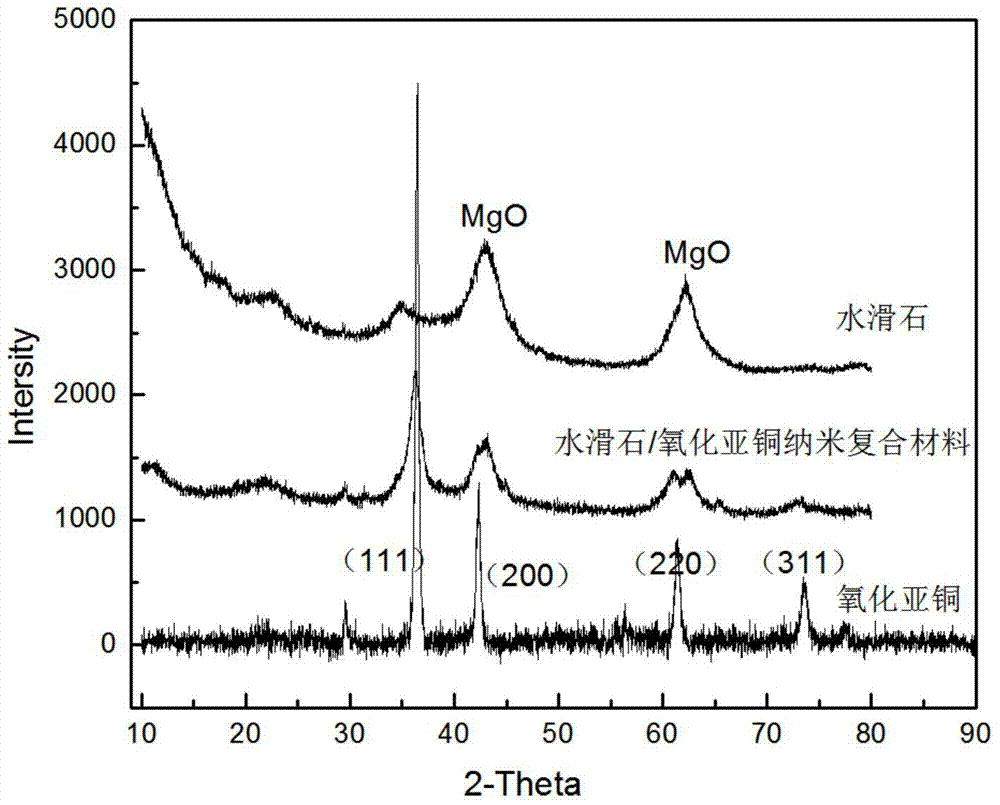

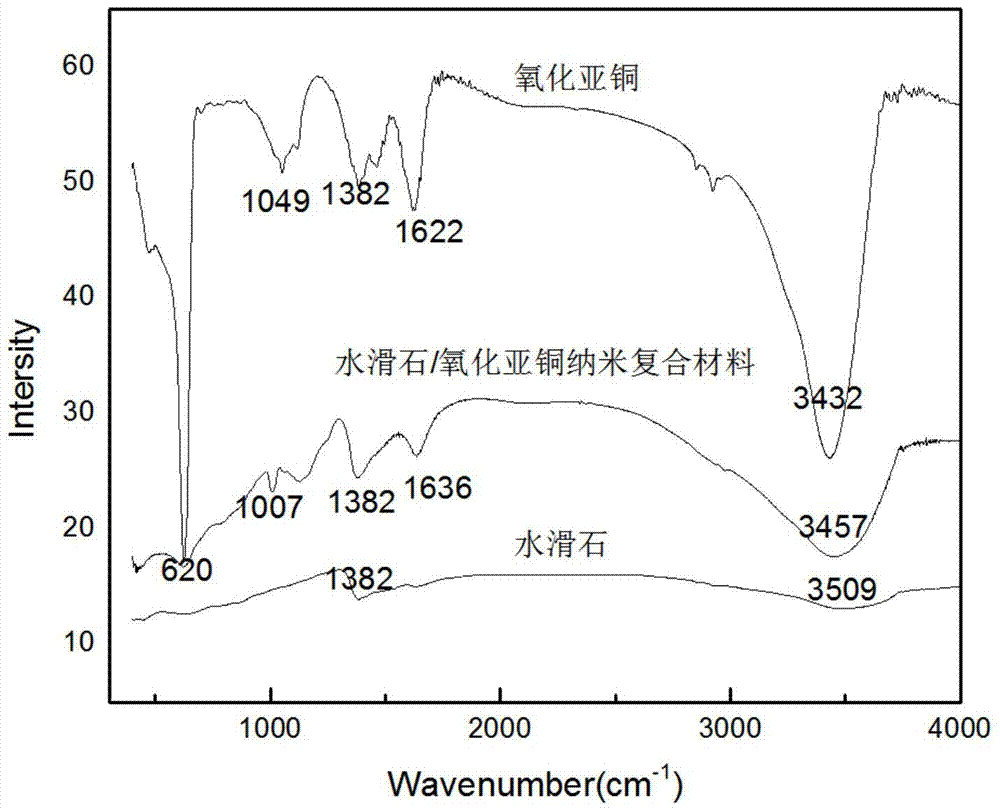

[0048] attached figure 1 , 2 Shown are the XRD pattern and FTIR pattern of the hydrotalcite / cuprous oxide nanocomposite material of this embodiment, respectively.

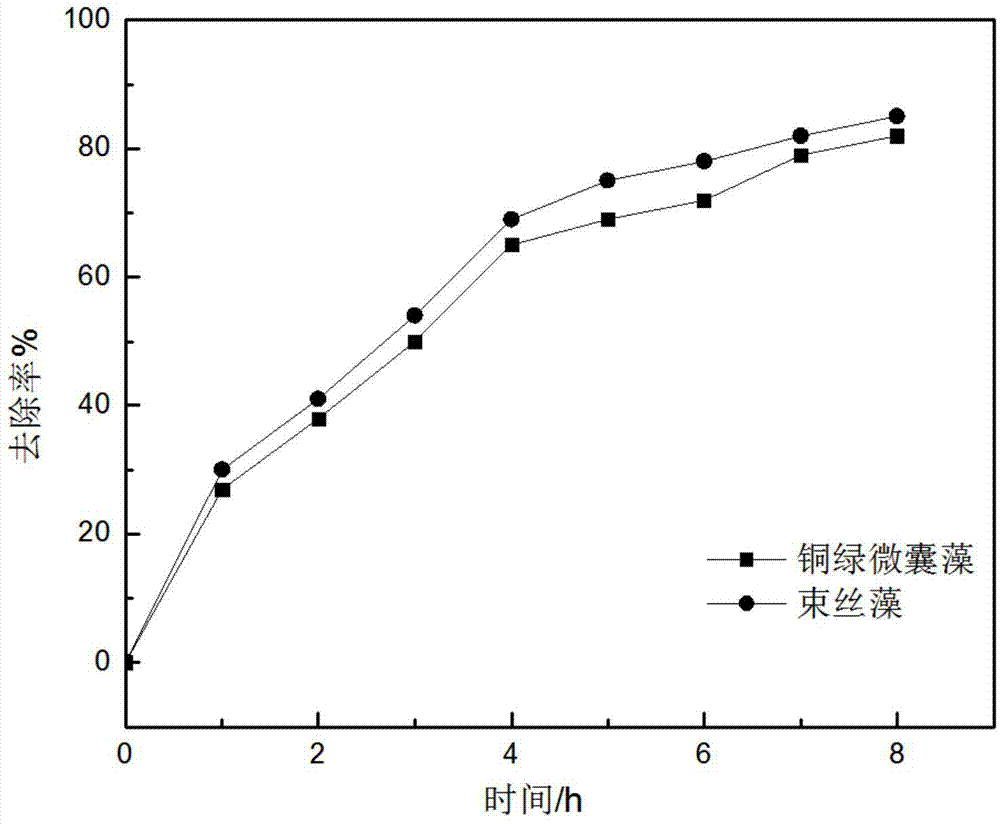

[0049]Dilute and mix the sterilized culture solution with the algae sample to prepare an algae suspension with a mass concentration of Microcystis aeruginosa of 1 mg / L (based on the mass concentration of chlorophyll a in algae cells), and place the algae suspension in a conical In the bottle, add hydrotalcite / cuprous oxide nanoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com