Quickly-dried oily osmosis film forming type nano composite protective agent as well as preparation method and application thereof

A nano-composite, film-forming technology, applied in the direction of coating, can solve the problems of difficult drying, reduced production efficiency, small micro-interaction, etc., to avoid the erosion of strong acid or alkali, improve acid and alkali resistance, The effect of increased steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

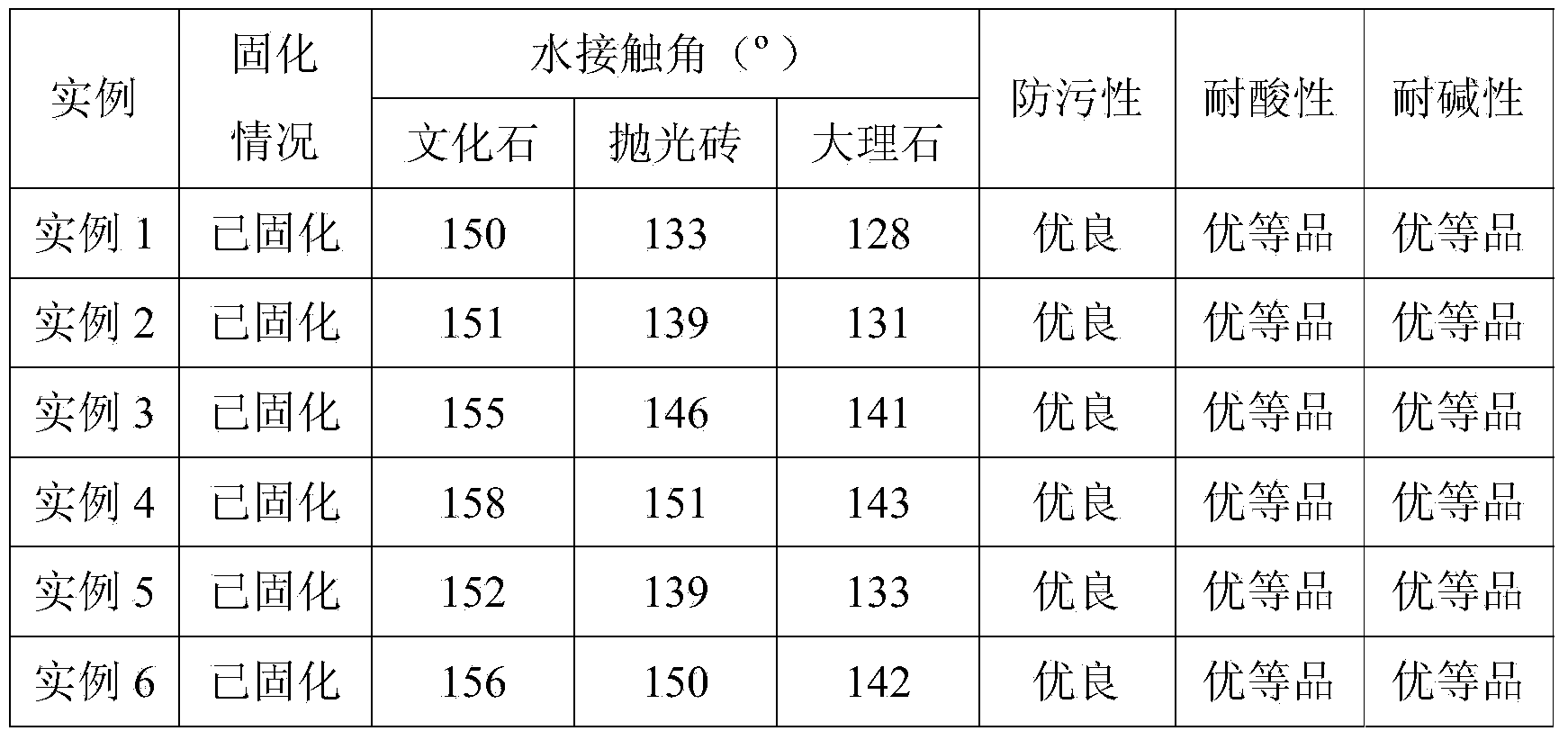

Examples

Embodiment 1

[0030] In a 250ml three-necked flask equipped with a reflux device, add 20g of high hydrogen-containing silicone oil (active hydrogen content (Si-H) is 1.5wt%), No. 120 solvent gasoline of 60g, and isooctyl acrylate of 36.8g, stir , add 0.30 g of platinum divinyltetramethyldisiloxane double head complex solution (Karsted catalyst) (the concentration of platinum is 1,000 ppm), heat to 70 ° C for 3 hours, cool, add 0.2 g No. 120 solvent gasoline solution of ethynyl cyclohexanol (the concentration of ethynyl cyclohexanol is 10wt%), the solvent is removed by natural volatilization, and the long-chain alkyl modified polymethylsiloxane PS1 containing active silicon-hydrogen bonds is obtained , wherein the remaining active hydrogen content is 0.5wt% of the raw material high hydrogen-containing silicone oil. Then take 110g of long-chain alkyl-modified polymethylsiloxane PS containing active silicon-hydrogen bonds, add 20g of No. 200 solvent gasoline, and add vinyl methyl MQ silicone r...

Embodiment 2

[0032]Add 20g of high hydrogen-containing silicone oil (active hydrogen content (Si-H) is 1.05wt%), 40g of No. 200 solvent naphtha, 48.6g of octadecyl acrylate successively in a 250ml three-necked flask equipped with a reflux device, stir , add 0.1 g of platinum divinyltetramethyldisiloxane double head complex solution (Karsted catalyst) (the concentration of platinum is 10,000 ppm), heat to 90 ° C for 3 hours, cool, add 1 g of acetylene No. 120 solvent gasoline solution of acetylcyclohexanol (the concentration of ethynylcyclohexanol is 10wt%), the natural volatilization removes solvent, makes the long-chain alkyl modified polymethylsiloxane PS2 containing active silicon-hydrogen bond, Wherein the remaining active hydrogen content is 0.25wt% of the raw material high hydrogen-containing silicone oil. Then take 210g of long-chain alkyl-modified polymethylsiloxane PS containing active silicon-hydrogen bonds, add 20g of No. 200 solvent gasoline, and add vinyl methyl MQ silicone re...

Embodiment 3

[0034] In a 250ml three-necked flask equipped with a reflux device, add 20g of high hydrogen-containing silicone oil (active hydrogen content (Si-H) is 1.05wt%), 40g of No. 200 solvent gasoline, 40g of dimethyl carbonate, 45.4g 1H,1H-perfluorooctyl acrylate (CH 2 =CHCOOCH 2 C 7 f 15 ), stirring, adding 0.3 g of platinum divinyltetramethyldisiloxane double head complex solution (Karsted catalyst) (the concentration of platinum is 1,500 ppm), heated to 70 ° C for 3 hours, cooled, Add 0.5g of ethynyl cyclohexanol No. 120 solvent gasoline solution (the concentration of ethynyl cyclohexanol is 10wt%), and naturally volatilize and remove the solvent to obtain a long-chain alkyl-modified polymethylsilane containing active silicon-hydrogen bonds Oxane PS3, wherein the remaining active hydrogen content is 0.45wt% of the raw material high hydrogen-containing silicone oil. Then take 310g of long-chain alkyl-modified polymethylsiloxane PS containing active silicon-hydrogen bonds, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com