A silver/titanium oxide nanotube antifouling agent interfacially modified by polydopamine and a preparing method thereof

A technology of titanium oxide nanotubes and polydopamine is applied in the field of composite nanomaterials and their preparation, and can solve the problems of restricting the development of environment-friendly and high-efficiency composite nanomaterials, complicated operation process of chemical etching method, uncontrollable etching morphology, etc. Achieve the effects of high popularization and application value, significant long-term bacteriostasis, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] a. Preparation of titanium oxide powder

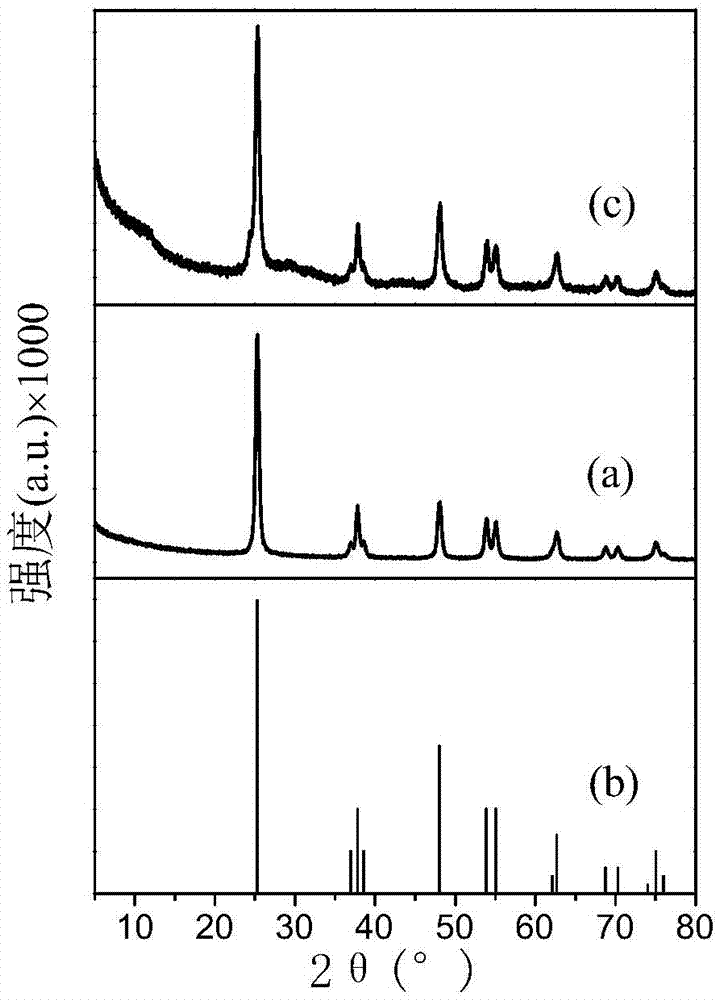

[0034] Add 30ml of tetrabutyl titanate to 105ml of absolute ethanol, stir for 25min, and mark the solution as solution A. Add 3ml of glacial acetic acid and 10ml of water to 105ml of absolute ethanol, mix well, and mark the solution as B solution. Slowly add liquid B to liquid A to prepare a transparent titanium oxide sol. The sol was left to stand for a period of time to obtain a gel. The prepared gel was placed in a constant temperature drying oven and dried at 80° C. for 12 hours to obtain a pale yellow xerogel. Finally, the dry gel was placed in a muffle furnace and calcined at 500°C for 4 hours, and the product was cooled to room temperature with the furnace. The XRD spectrum of the obtained titanium oxide powder is shown in figure 1 -a. As can be seen from the figure, each XRD diffraction spectrum peak of titanium oxide powder all corresponds to each diffraction spectrum peak of anatase type titanium oxide standard po...

Embodiment 2

[0042] a. Preparation of titanium oxide powder

[0043] Add 30ml of tetrabutyl titanate to 105ml of absolute ethanol, stir for 25min, and mark the solution as A solution. Add 3ml of glacial acetic acid and 10ml of water to 105ml of absolute ethanol, mix well, and mark the solution as B solution. Slowly add liquid B dropwise into liquid A to obtain a translucent titanium oxide sol. The sol was left to stand for a period of time to obtain a gel. The prepared gel was placed in a constant temperature drying oven and dried at 80° C. for 12 hours to obtain a pale yellow xerogel. Finally, the dry gel was placed in a muffle furnace and calcined at 500°C for 4 hours, and the product was cooled to room temperature with the furnace.

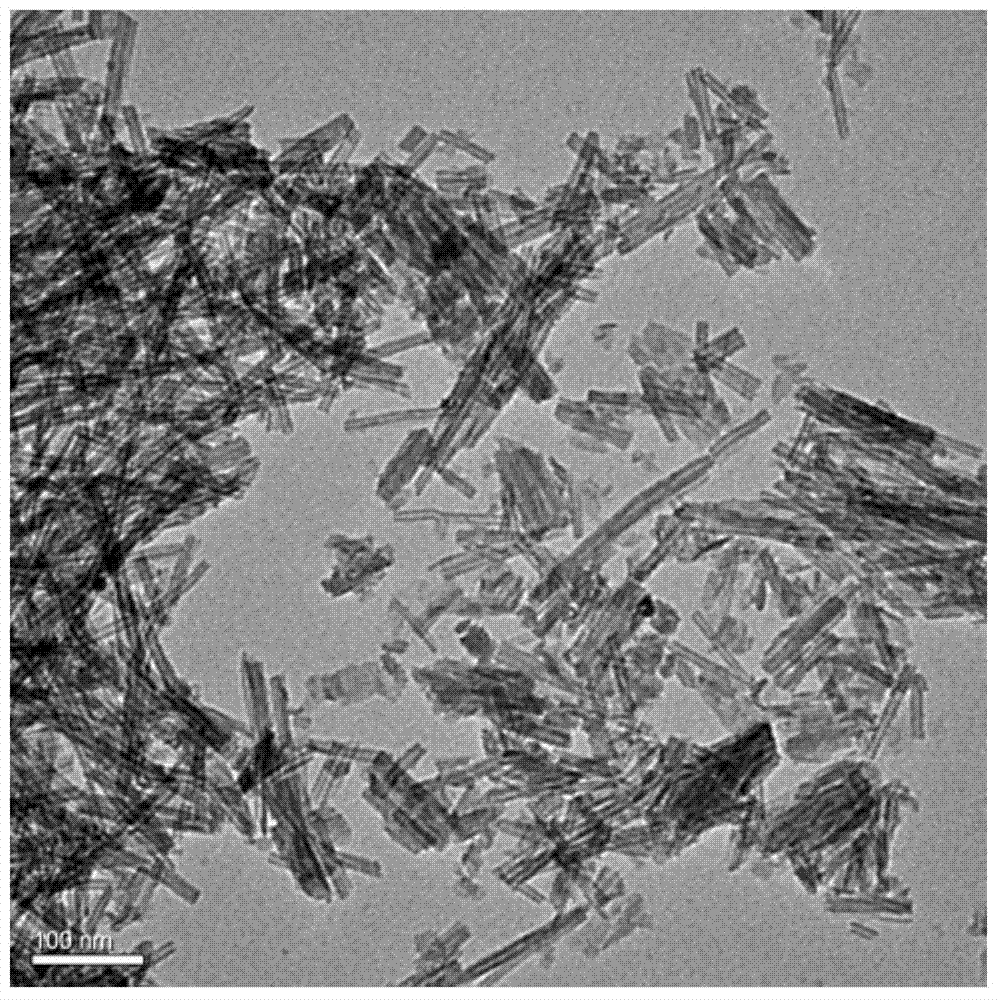

[0044] b. Preparation of titania nanotubes

[0045] Prepare 130ml of 10mol / L sodium hydroxide solution, add 0.5g of titanium oxide powder and mix evenly, move it into the lining of a hydrothermal kettle, seal it, place it in a constant temperature dryin...

Embodiment 3

[0051] a. Preparation of titanium oxide powder

[0052] Add 30ml of tetrabutyl titanate to 105ml of absolute ethanol, stir for 25min, and mark the solution as A solution. Add 3ml of glacial acetic acid and 10ml of water to 105ml of absolute ethanol, mix well, and mark the solution as B solution. Slowly add liquid B dropwise into liquid A to obtain a translucent titanium oxide sol. The sol was left to stand for a period of time to obtain a gel. The prepared gel was placed in a constant temperature drying oven and dried at 80° C. for 12 hours to obtain a pale yellow xerogel. Finally, the dry gel was placed in a muffle furnace and calcined at 500°C for 4 hours, and the product was cooled to room temperature with the furnace.

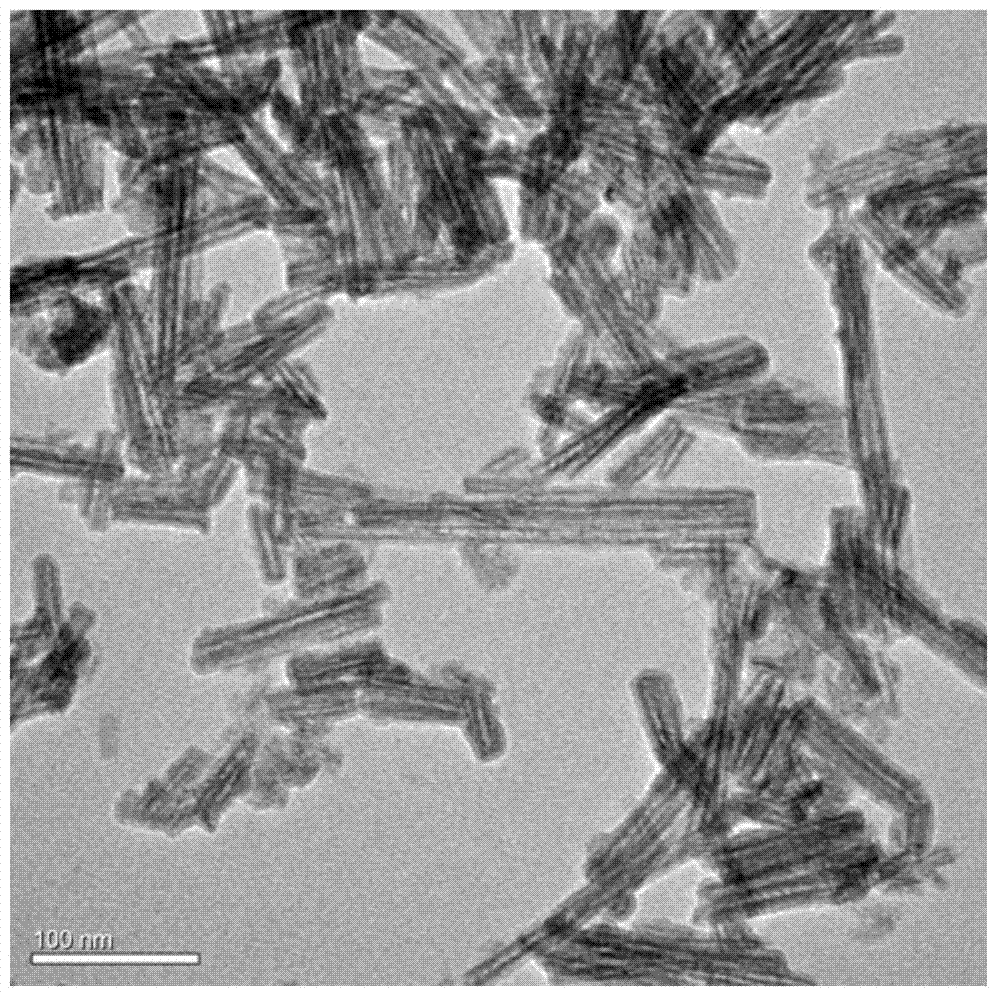

[0053] b. Preparation of titania nanotubes

[0054] Prepare 130ml of 10mol / L sodium hydroxide solution, add 0.5g of titanium oxide powder and mix evenly, move it into the lining of a hydrothermal kettle, seal it, place it in a constant temperature dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com