Biological deodorant and preparation method thereof

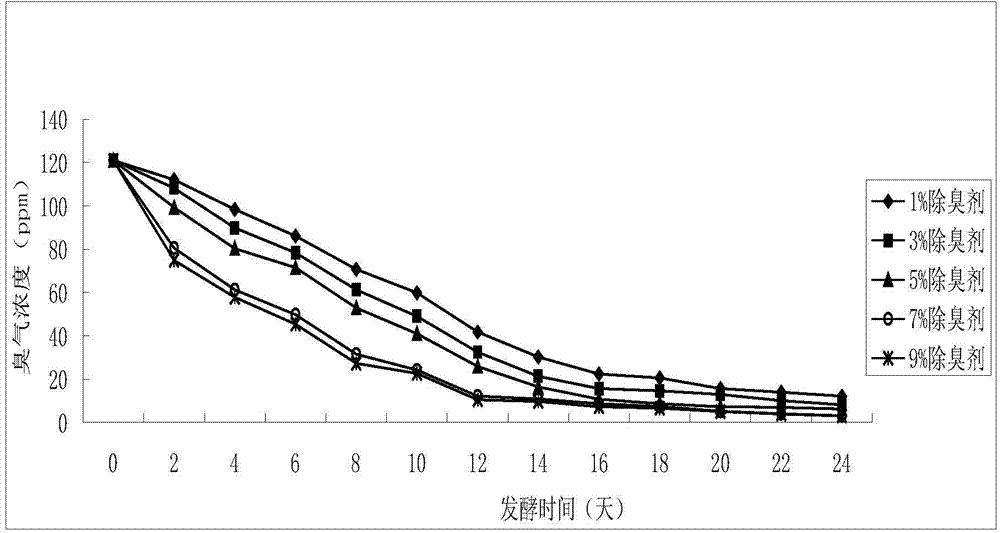

A biological deodorant and microorganism technology, applied in the fields of deodorization, organic fertilizer preparation, biological organic part treatment, etc., can solve the problem that the generation of odorous gas cannot be reduced, the odorous odor cannot be effectively removed, and the composting process cannot be accelerated. and other problems, to achieve the effect of improving the effect, accelerating the decay and stabilizing, and achieving high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of biological deodorant is characterized in that, is made up of the raw material of following percentage by weight:

[0027] 20% microbial compound bacteria agent, 40% organic acid, 40% superphosphate;

[0028] Described microbial composite bacterial agent comprises Saccharomyces cerevisiae, Bacillus subtilis, Lactobacillus delbrueckii, Nitrifying bacteria, Thiobacillus oxidans, Acetobacter oxidans and bentonite, the weight ratio of each component is:

[0029] Brewer's yeast: Bacillus subtilis: Lactobacillus delbrueckii: Nitrifying bacteria: Thiobacillus oxidans: Acetobacter oxidans: Bentonite=1:1:1:1:1:1:10.

[0030] Described organic acid comprises 10% oleic acid, 10% linoleic acid, 10% linolenic acid, 10% arachidonic acid, 10% tartaric acid, 10% oxalic acid, 10% malic acid, 10% amino acid, 10% sulfonic acid and 10% sulfinic acid.

[0031] A preparation method of biological deodorant, comprising the following steps:

[0032] 1) Preparation of microbial compo...

Embodiment 2

[0035] A kind of biological deodorant is characterized in that, is made up of the raw material of following percentage by weight:

[0036] 30% microbial compound bacteria agent, 40% organic acid, 30% superphosphate;

[0037] Said microbial compound bacterial agent comprises Saccharomyces cerevisiae, Bacillus subtilis, Lactobacillus delbrueckii, Nitrifying bacteria, Thiobacillus oxidans, Acetobacter oxidans and Attapulgite, and the weight ratio of each component is:

[0038] Brewer's yeast: Bacillus subtilis: Lactobacillus delbrueckii: Nitrifying bacteria: Thiobacillus oxidans: Acetobacter oxidans: Attapulgite=1:3:3:1:3:1:15;

[0039] The organic acids include 30% oleic acid, 20% linoleic acid, 20% linolenic acid, 10% arachidonic acid, 10% citric acid and 10% amino acid.

[0040] A preparation method of biological deodorant, comprising the following steps:

[0041] 1) Preparation of microbial compound bacteria agent: Saccharomyces cerevisiae, Bacillus subtilis, Lactobacillus ...

Embodiment 3

[0044] A kind of biological deodorant is characterized in that, is made up of the raw material of following percentage by weight:

[0045] 20% microbial compound bacteria agent, 50% organic acid, 30% superphosphate;

[0046] Described microbial compound bacterial agent comprises Saccharomyces cerevisiae, Bacillus subtilis, Lactobacillus delbrueckii, Nitrifying bacteria, Thiobacillus oxidans, Acetobacter oxidans and zeolite, the weight ratio of each component is:

[0047] Brewer's yeast: Bacillus subtilis: Lactobacillus delbrueckii: Nitrifying bacteria: Thiobacillus oxidans: Acetobacter oxidans: Zeolite = 1:1:3:1:3:1:12;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com