Higher-heat-stability amylase mutant, and preparation method and application thereof

A technology of thermal stability and amylase, applied in the field of enzyme engineering, can solve problems such as poor stability, and achieve the effects of improved thermal stability, efficient degradation and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

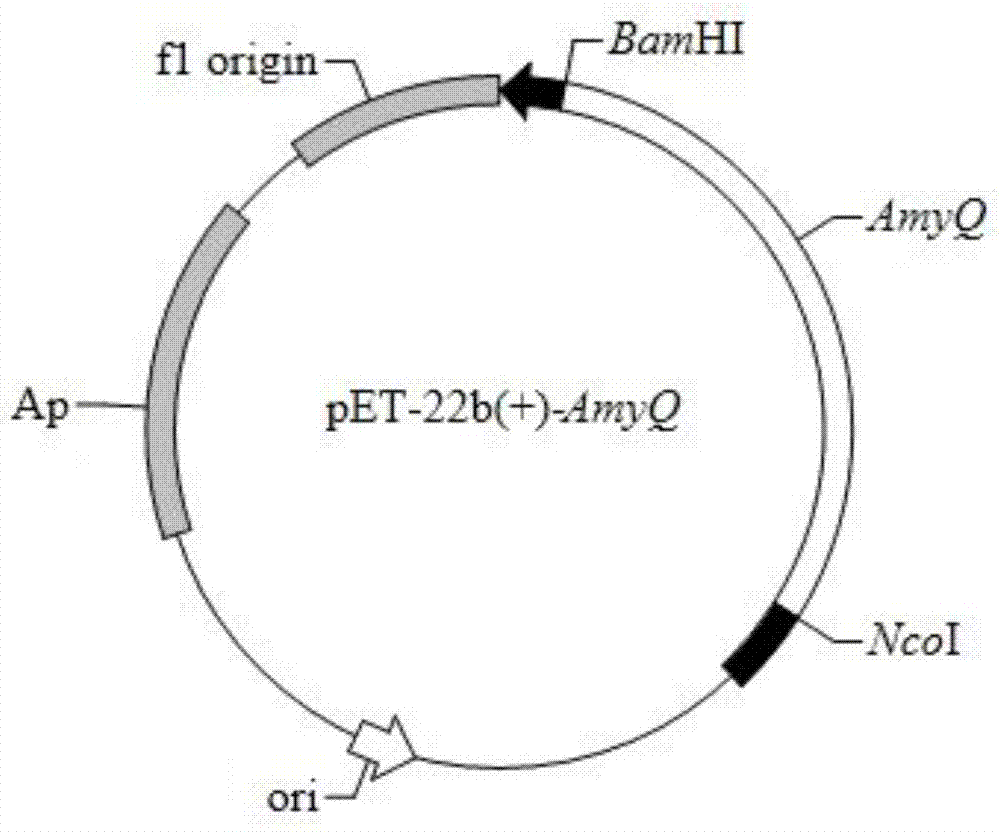

[0021] Example 1 Determination of Amylase Mutation Sites and Obtaining of Mutants

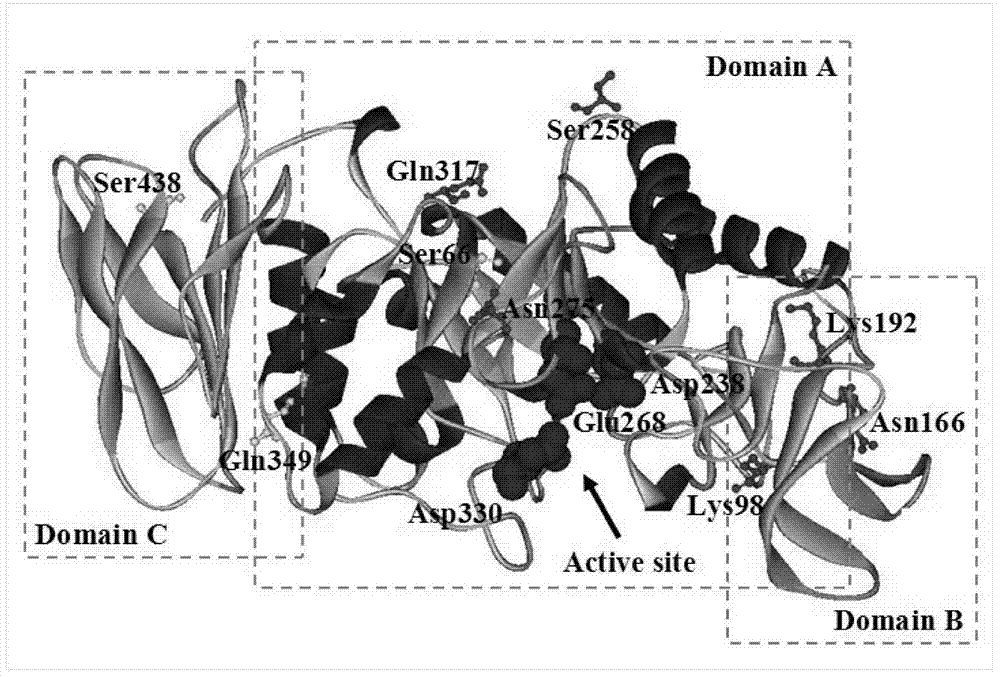

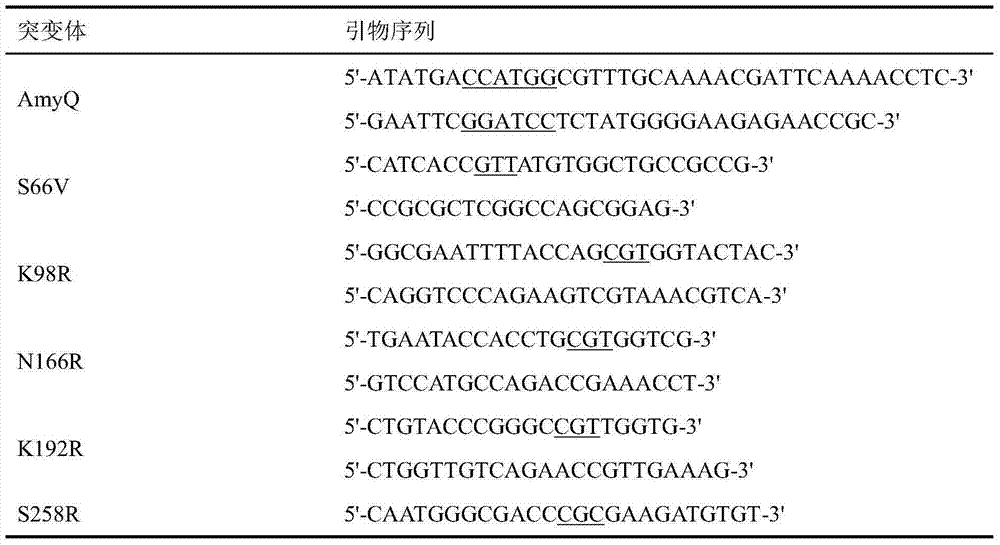

[0022] The amylase (SEQ ID NO.1) derived from Bacillus alkalophilus was simulated by Swiss-model software, based on the amylase spatial structure model obtained, and the solvent availability of all amino acids in the enzyme protein molecule was calculated using Macrodox software. Contact area. On the one hand, select lysine, asparagine, glutamine, and serine located on the surface of the protein (solvent accessible area is greater than 100 Å), and replace them with arginine to enhance the electrostatic interaction on the protein surface, and analyze the corresponding positions at the same time. The effect of amino acid mutation at the point on the formation of hydrogen bonds and salt bridges inside the enzyme molecule was determined to carry out amino acid substitutions at the following positions: Lys 98Arg, Asn 166Arg, Lys 192Arg, Ser 258Arg, Asn 275Arg and Gln 317Arg. On the other hand, sele...

Embodiment 2

[0028] Example 2 Amylase thermostability site-directed mutation analysis and method

[0029] Determination of alkaline amylase activity by DNS method:

[0030] 1) Preparation of DNS reagent: Weigh 3.25g of 3,5-dinitrosalicylic acid and dissolve it in a small amount of water, transfer it into a 500mL volumetric flask, add 162.5mL of 2mol / L sodium hydroxide solution, and then add 22.5g of glycerol, Shake well, dilute to 500mL, store in a brown bottle and place in a refrigerator at 4°C until use.

[0031] 2) Preparation of glucose standard curve: glucose solutions with different concentrations of 0.2g / L-1.0g / L were prepared. Take 1mL of different concentrations of glucose and mix it with the same volume of DNS solution, put it in a boiling water bath, and keep the water bath for 10min. Cool with cold water, dilute to 10mL, A 540 Measure the absorbance. Take the concentration of glucose as the abscissa and the absorbance as the ordinate to make a standard curve.

[0032] 3) A...

Embodiment 3

[0036] The thermostability determination analysis of embodiment 3 amylase at 60 ℃

[0037]It was found by measurement that the half-lives of the single mutants S66V, K98R, N166R, K192R, S258R, N275R, Q317R, Q349V and S438V were all increased at 60°C (Table 2), among which Q317R had the most significant effect, and the half-life was increased to 1.8 times the original . On this basis, compound mutations were carried out, and six single mutants that enhanced electrostatic interaction were compounded to obtain a six-mutant K98R / N166R / K192R / S258R / N275R / Q317R, and three single mutants that enhanced hydrophobic interaction were compounded A triple mutant S66V / Q349V / S438V was obtained. Finally, a nine-mutant S66V / K98R / N166R / K192R / S258R / N275R / Q317R / Q349V / S438V was obtained by introducing all nine amino acid substitutions into the catalytic domain of amylase. It was found by measurement that their half-lives at 60° C. (Table 3) were all improved, and the effect of the mutant with 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com