Method for removing hexavalent molybdenum in water

A technology of aqueous solutions and derivatives, applied in chemical instruments and methods, water/sewage treatment, adsorption water/sewage treatment, etc., can solve problems such as high operating costs, secondary pollution, and difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] A method for removing hexavalent molybdenum in water comprises the steps:

[0080] (1) Disperse graphite oxide powder in ultrapure water to obtain a graphite oxide dispersion with a concentration of 1.5 mg / mL, ultrasonicate in a water bath for 2 hours, and ultrasonic power 150W to obtain a graphene oxide dispersion;

[0081] (2) Add a small amount of ammonia water to the graphene oxide dispersion obtained in step (1), adjust the pH to 10, and add hydrazine hydrate to the dispersion for 10 minutes for ultrasonic dispersion according to the ratio of hydrazine to graphite oxide mass ratio of 7:10 , mixed evenly to obtain a mixed dispersion; keep the mixed dispersion in a water bath at 95 ° C, magnetically stir at 300 rpm, and carry out a reflux reaction for 24 hours; use a high-speed centrifuge to separate the solid product, and wash and centrifuge it with ultrapure water several times. ℃ drying to obtain the reduced graphene oxide material;

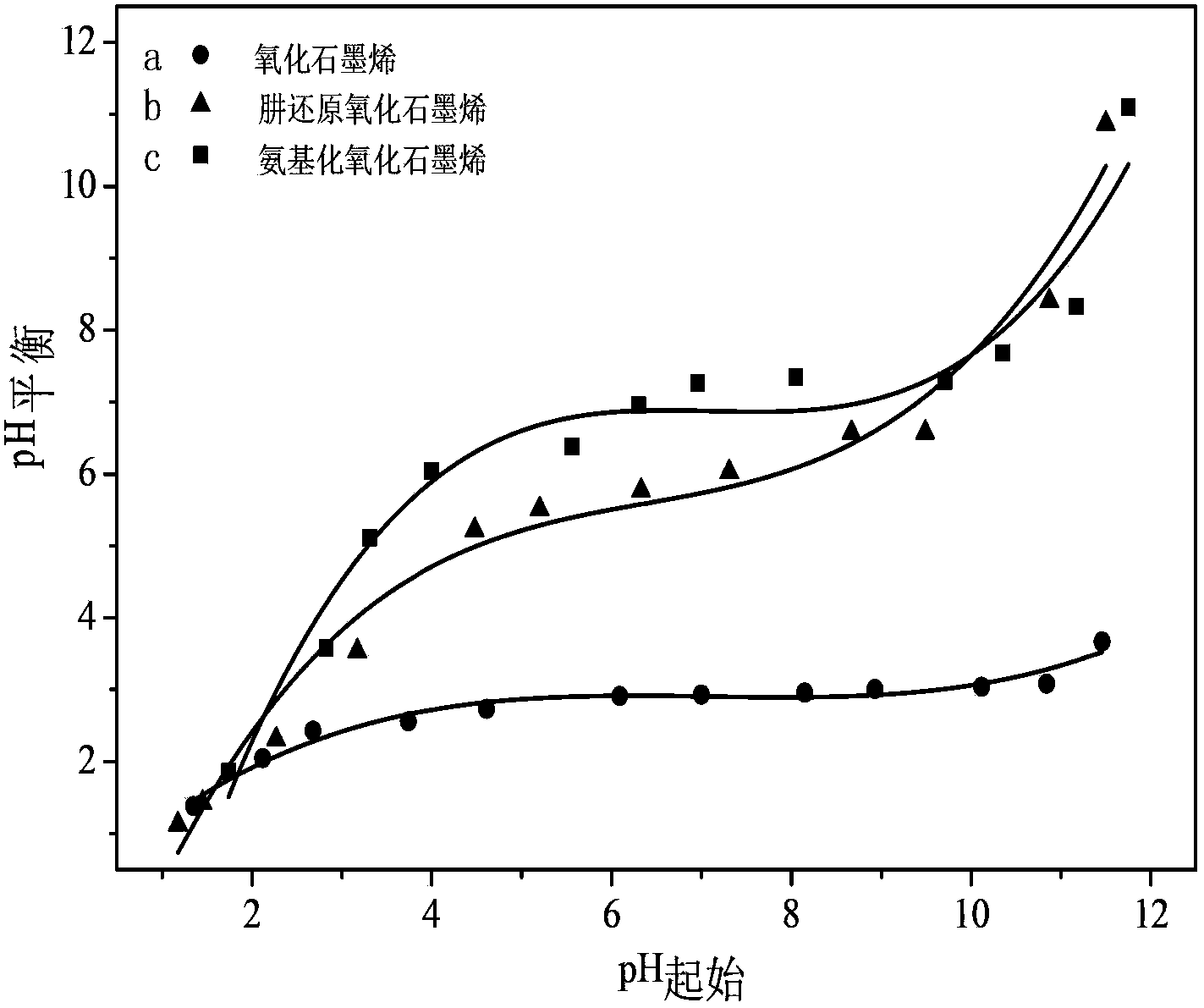

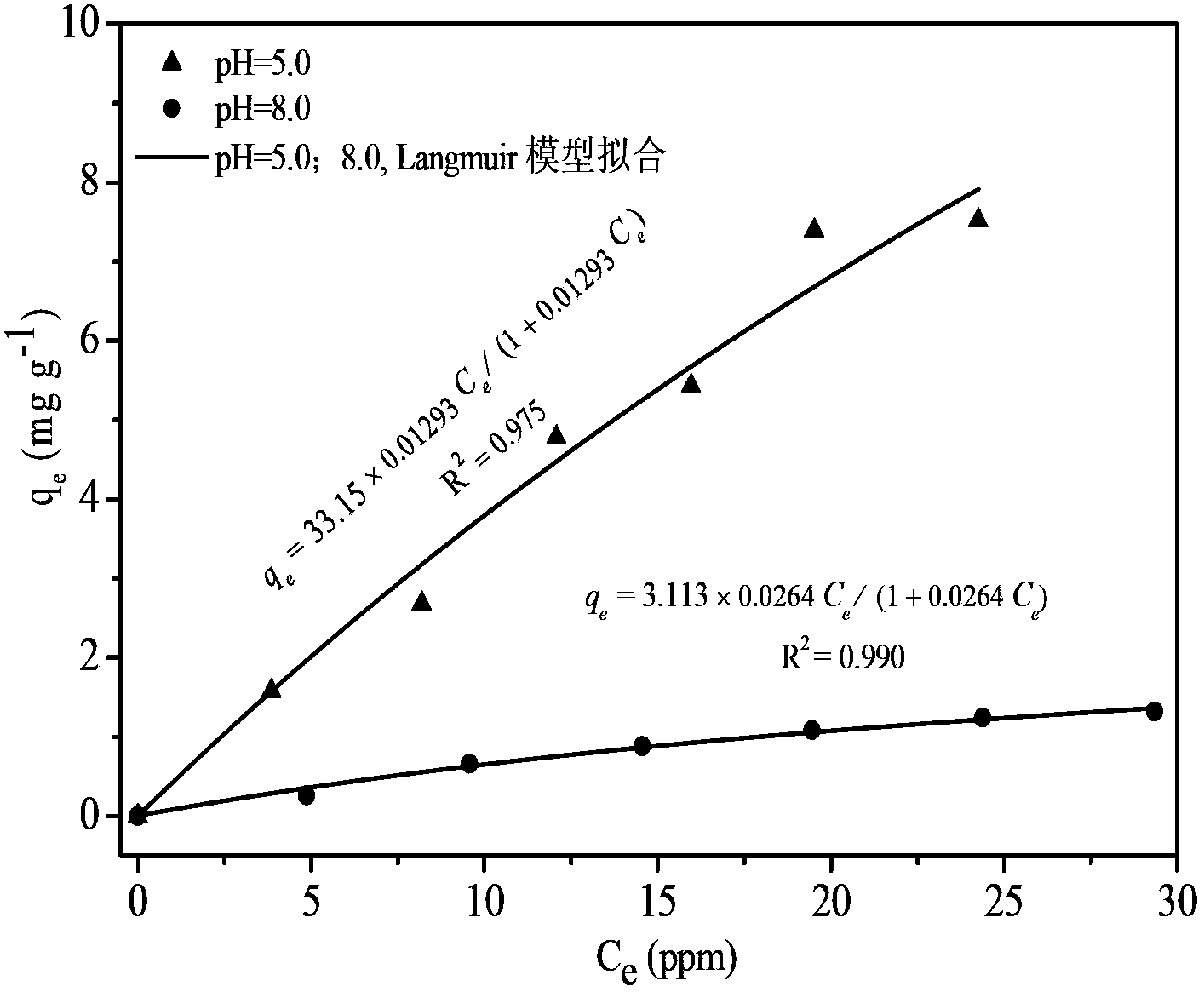

[0082] (3) The PZC of the re...

Embodiment 2

[0091] A method for removing hexavalent molybdenum in water comprises the steps:

[0092] (1) Disperse the graphite oxide powder in ultrapure water to obtain a 1mg / ml graphite oxide aqueous dispersion, and ultrasonically treat it in a water bath for 2 hours with an ultrasonic power of 150W to obtain a graphene oxide dispersion;

[0093] (2) Disperse p-phenylenediamine in ethanol to obtain a 3mg / ml ethanol dispersion of p-phenylenediamine, mix the graphene oxide dispersion and p-phenylenediamine ethanol dispersion in equal volumes, and ultrasonically mix for 30 minutes to obtain Mix the dispersion; heat the mixed solution in a water bath at 95°C, magnetically stir at 300rpm, and reflux for 24 hours; use a high-speed centrifuge to separate the solid product, wash and centrifuge it with ultrapure water several times, and dry it at 55°C to obtain the amination oxidation Graphene derivative materials;

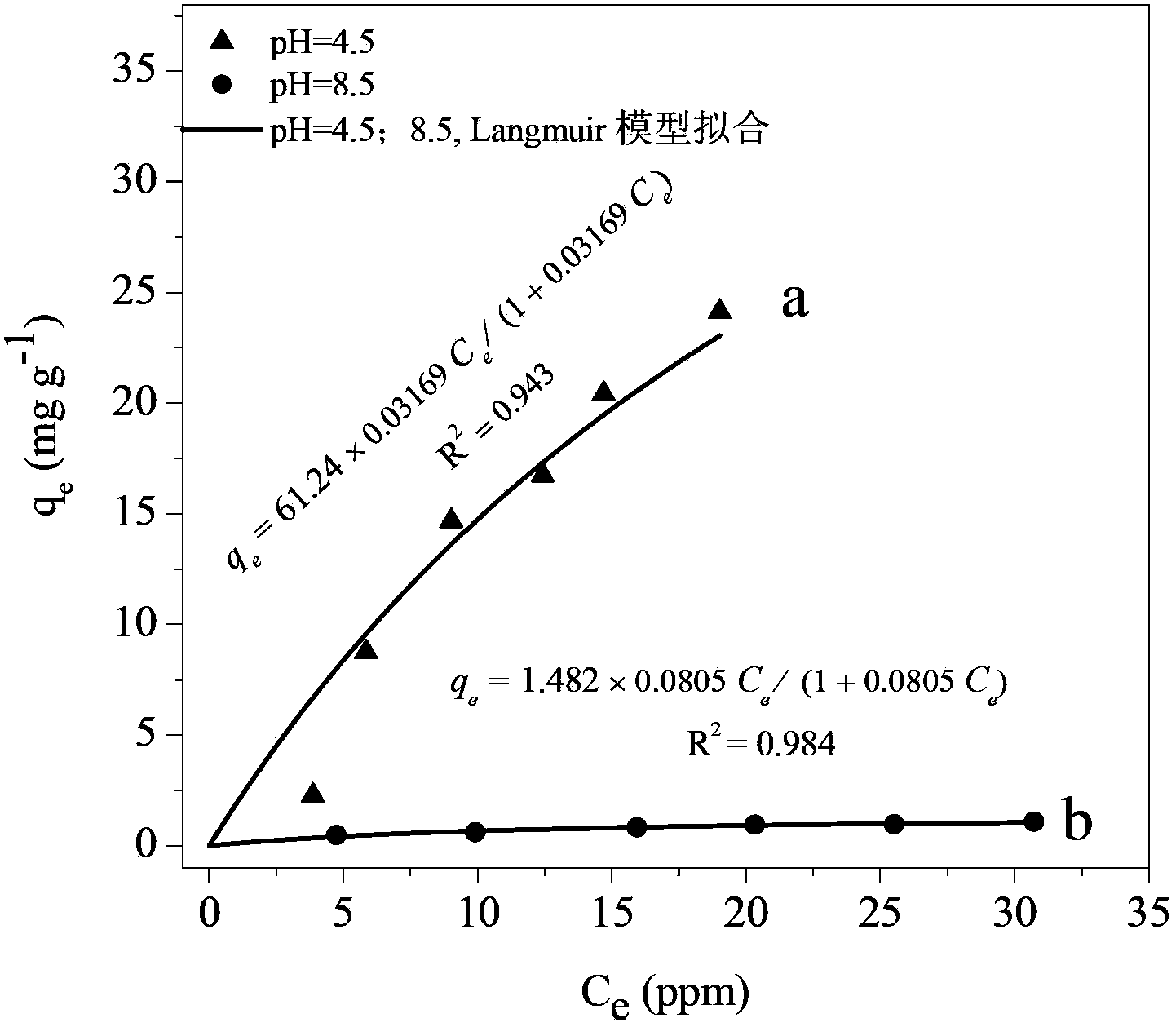

[0094] (3) The PZC of the aminated graphene oxide derivative material obtained...

Embodiment 3

[0104] A method for removing hexavalent molybdenum in water comprises the steps:

[0105] (1) Disperse graphite oxide in a solvent, ultrasonically treat it in a water bath for 0.5 h, and prepare a graphene oxide dispersion with a concentration of 5 mg / mL;

[0106] (2) Add ammonia water (1000 times the mass of graphene oxide) to the graphene oxide dispersion prepared in step (1), and ultrasonically disperse in a water bath for 5 minutes to obtain a mixed dispersion; put the mixed dispersion in a condensed reflux In the round-bottom flask of the tube, stir and reflux for 36 hours, and keep the temperature of the water bath at 95°C; after the reaction is completed, the solid obtained by centrifugation is the reaction product, washed with lotion, and dried at 25°C to obtain the reduced graphene oxide material;

[0107] (3) The PZC of the reduced graphene oxide material obtained in step (2) is about 4, which is about 1 higher than the PZC3 of graphene oxide by the batch equilibriu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum equilibrium adsorption capacity | aaaaa | aaaaa |

| Maximum equilibrium adsorption capacity | aaaaa | aaaaa |

| Maximum equilibrium adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com