Composite graphite material, method for producing same, negative electrode material for lithium ion secondary batteries, negative electrode for lithium ion secondary batteries, and lithium ion secondary battery

A technology of composite graphite and graphite materials, which is applied in the direction of secondary batteries, lithium batteries, battery electrodes, etc., can solve the problems of rapid charging and discharging and cycle characteristics degradation, unstable viscosity of negative electrode mixture paste, and expensive carbon fiber, etc., to achieve charging and discharging Excellent efficiency and cycle characteristics, effective miniaturization and high performance, and high rapid charging rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0180] (Preparation of Adhesive A)

[0181] 50 mass parts of tar pitches were dissolved in 50 mass parts of tar medium oils, and the precursor solution of the binder A was obtained.

[0182] (Preparation of flaky graphite material B)

[0183] Natural graphite was pulverized with adjustment so that the obtained scaly graphite material B had an average particle diameter of 4 μm and an average aspect ratio of 35. The d002 of the obtained flaky graphite material B was 0.3357 nm.

[0184] (modulation of graphite material C)

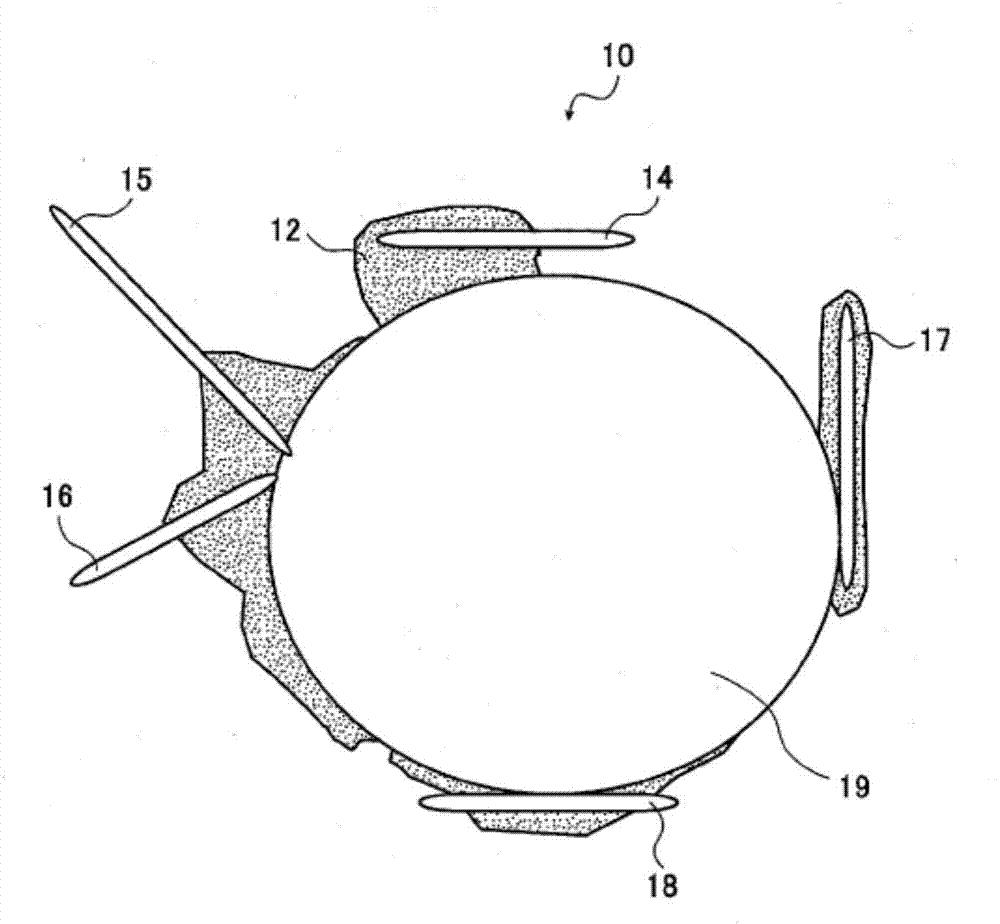

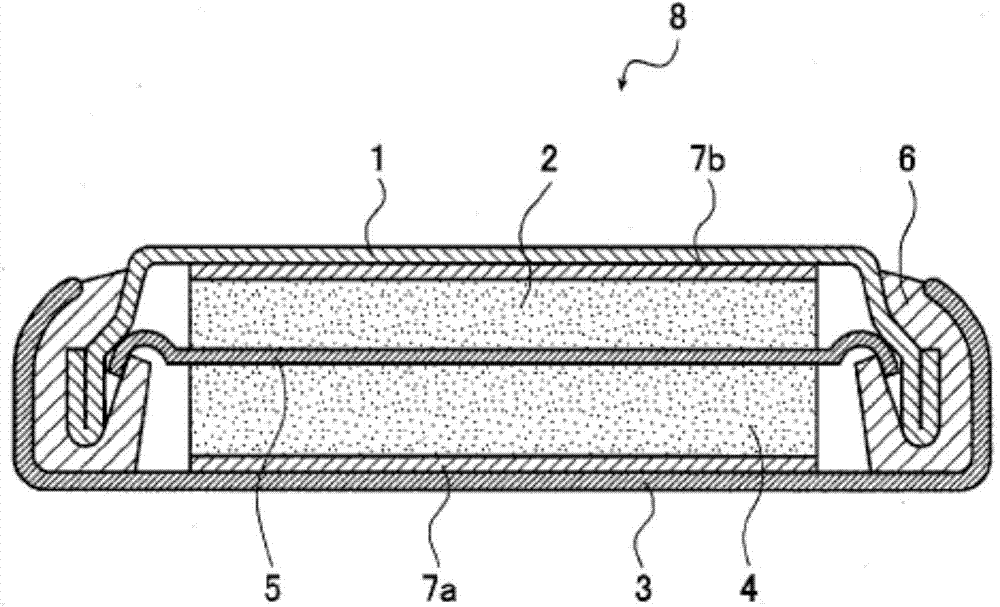

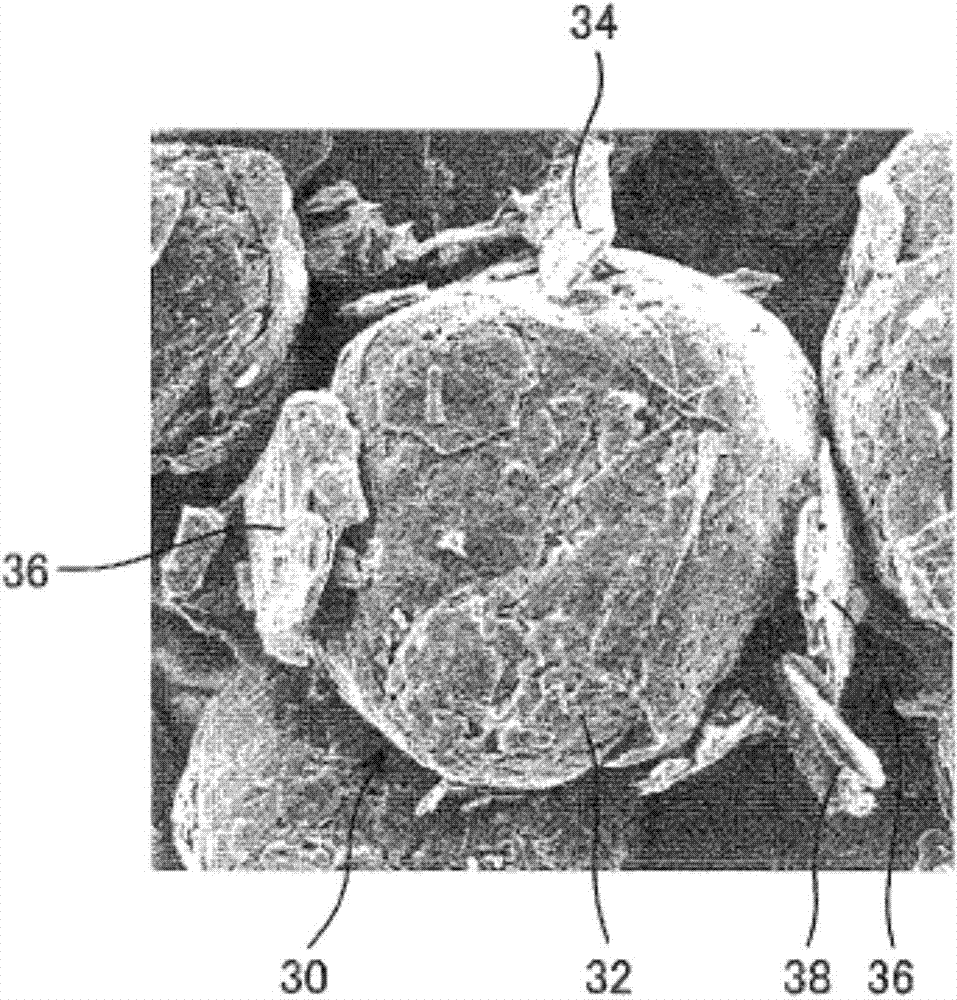

[0185] Spherical granulation was obtained by circulating flaky natural graphite (average particle size: 20 μm) in a back jet mill (manufactured by Hosokawa Micron; model 200AFG) at an air pressure of 300 kPa for 1 hour while applying mechanical force Natural graphite. Then, incompletely granulated micropowder with a particle diameter of 5 μm or less is removed. The coarse powder was then removed to form a 75 μm under-sieve particle. When the cross-sectio...

Embodiment 2

[0219] Except that the ratio of flaky graphite material B is 10 parts by mass and the ratio of graphite material C is 86.5 parts by mass in Example 1, a composite graphite material is prepared in the same manner as in Example 1, and negative electrodes and The battery was evaluated, and an evaluation test was performed in the same manner as in Example 1. Table 1 and Table 2 show the evaluation results of battery characteristics.

Embodiment 3

[0221] Except that the ratio of the flaky graphite material B is 25 parts by mass and the ratio of the graphite material C is 71.5 parts by mass in Example 1, the composite graphite material is prepared in the same manner as in Example 1, and the negative electrode and The battery was evaluated, and an evaluation test was performed in the same manner as in Example 1. Table 1 and Table 2 show the evaluation results of battery characteristics.

[0222]As shown in Tables 1 and 2, the evaluation batteries obtained by using the composite graphite materials of Examples 1 to 3 as the working electrodes exhibited high discharge capacities and high initial charge and discharge efficiencies. It also exhibits excellent fast charge-discharge efficiency and excellent cycle characteristics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com