Carbon-based photocatalytic oxidation denitration catalyst and preparation method thereof

A denitration catalyst and photocatalytic oxidation technology are applied in the field of carbon-based photocatalytic oxidation removing NO catalyst and its preparation, which can solve the problems of narrow spectral absorption range, large equipment investment and high operating cost, achieve low price and improve denitration performance. , the effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

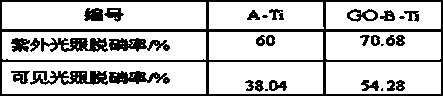

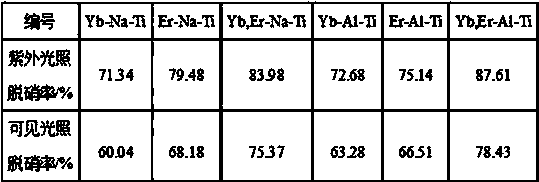

[0035] Weigh 23.50 mg of up-conversion luminescent material Yb containing rare earth ions 3+ : NaYF 4 、 Er 3+ : NaYF 4 , (Yb 3+ , Er 3+ ): NaYF 4 , Yb 3+ :YAlO 3 、Er 3+ :YAlO 3 , (Yb 3+ , Er 3+ ): YAlO 3 , were added to a beaker containing 30ml of absolute ethanol, and 1ml of n-butyl titanate was added dropwise while stirring, and kept stirring for 30min; 0.145ml of acetic acid and 0.175ml of deionized water, stir well and add it to the above solution, keep stirring for 1h. Grind semi-coke to 4-10 mesh, oxidize it with nitric acid, and activate it with high-temperature water vapor to obtain activated semi-coke or extrude the activated semi-coke powder (4-10 mesh), and weigh 23.5g of activated semi-coke by ultrasonic Immerse into the above mixed solution and keep for 30min. The mixture was transferred to a 100ml polytetrafluoroethylene hydrothermal reactor and kept at a constant temperature of 150°C for 5h. The semi-coke after the reaction was washed with dist...

Embodiment 7-12

[0041] Add 30ml of absolute ethanol to the beaker, add 18.80mg of graphite oxide, and after ultrasonication for 2 hours, add 23.50mg of up-conversion luminescent material Yb containing rare earth ions 3+ : NaYF 4 、Er 3+ : NaYF 4 , (Yb 3+ , Er 3+ ): NaYF 4 , Yb 3+ :YAlO 3 、Er 3+ :YAlO 3 , (Yb 3+ , Er 3+ ): YAlO 3 , Add 1ml of n-butyl titanate dropwise while stirring, and keep stirring for 30min; add 0.145ml of acetic acid and 0.175ml of deionized water into a beaker filled with 15ml of absolute ethanol, stir well and add them to the above solution , keep stirring for 1h. Grind semi-coke to 4-10 mesh, oxidize it with nitric acid, and activate it with high-temperature water vapor to obtain activated semi-coke or extrude the activated semi-coke powder (4-10 mesh), and weigh 23.5g of activated semi-coke by ultrasonic Immerse into the above mixed solution and keep for 30min. The mixture was transferred to a 100ml polytetrafluoroethylene hydrothermal reactor and kept at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com