A kind of diffusion bonding method of graphite and low carbon steel, stainless steel

A technology of diffusion connection and low-carbon steel, which is applied in the field of connection between graphite and low-carbon steel, inorganic non-metallic materials and metals, and diffusion connection of stainless steel, to achieve the effect of convenient process, convenient operation and promotion of diffusion bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

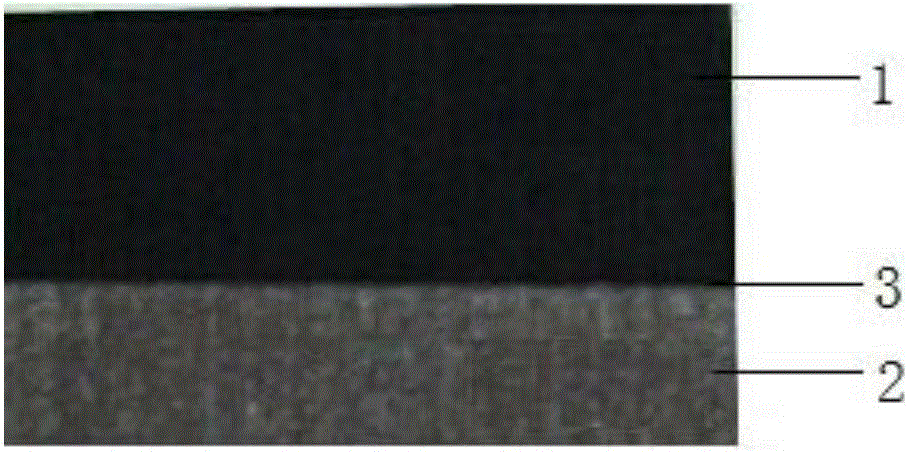

[0023] Diffusion connection of graphite with a length of 60mm, a width of 40mm, and a thickness of 20mm and Q235 low-carbon steel of the same size, the connection surface is 60mm×40mm contact surface. A quasi-crystalline titanium-copper foil with a thickness of 30 μm is used as the middle layer. The process steps are:

[0024] (1) Wipe the surface of the graphite to be connected with alcohol to remove oil stains and sundries on the surface; use a hydrochloric acid solution with a concentration of 15% to remove the rust on the surface of the Q235 low carbon steel to be connected.

[0025] (2) Use quasi-crystalline titanium copper metal foil with a purity greater than 99% as the active intermediate layer, and the chemical composition (by mass percentage) of the quasi-crystalline titanium copper metal foil is: Cu8.5%, C0.06%, Fe0.20 %, Si0.8%, the rest is Ti.

[0026] (3) Place the quasicrystalline titanium copper metal foil between the high-strength graphite and the low-carbon...

Embodiment 2

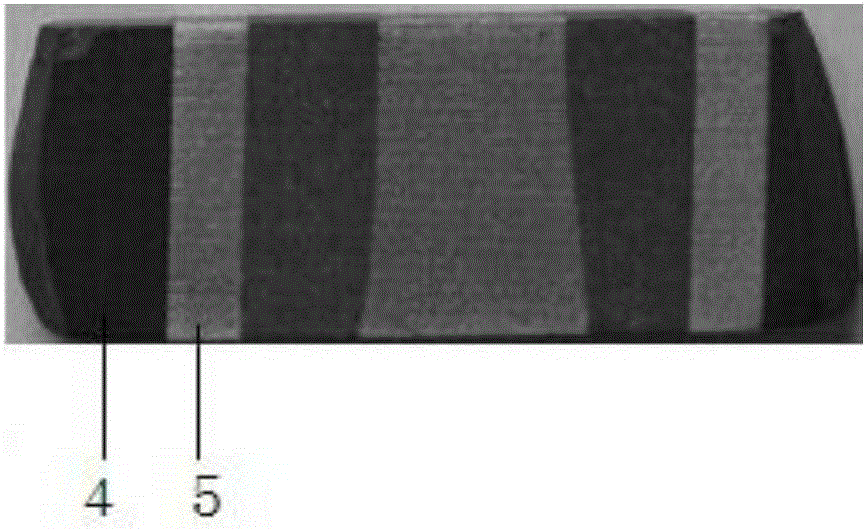

[0034] Diffusion connection of flake graphite with a diameter of 50mm and a thickness of 30mm and Cr18-Ni8 stainless steel of the same size, the connection surface is a circular contact surface with a diameter of 50mm. A quasi-crystalline titanium-copper foil with a thickness of 50 μm is used as the middle layer. The process steps are:

[0035] (1) Machining the graphite and Cr18-Ni8 stainless steel to be connected is smooth, and the Cr18-Ni8 stainless steel is polished with sandpaper until the metallic luster is exposed.

[0036] (2) Use quasi-crystalline titanium copper metal foil with a purity greater than 99% as the active intermediate layer. The chemical composition (by mass percentage) of the quasi-crystalline titanium copper metal foil is: Cu9.5%, C0.08%, Fe0.22 %, Si0.8%, the rest is Ti.

[0037] (3) Place the disc-shaped quasicrystalline titanium-copper metal foil between the graphite and the Cr18-Ni8 stainless steel surface to be connected, stack and assemble the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com