Preparation method of carbon nanotube modified by alkynyl on surface

A carbon nanotube and surface modification technology, used in the fields of chemistry and materials, can solve the problems of carbon nanotubes, such as high destructiveness, inability to be widely used, complex synthesis, etc., to achieve easy availability of raw materials, less damage, and good repeatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

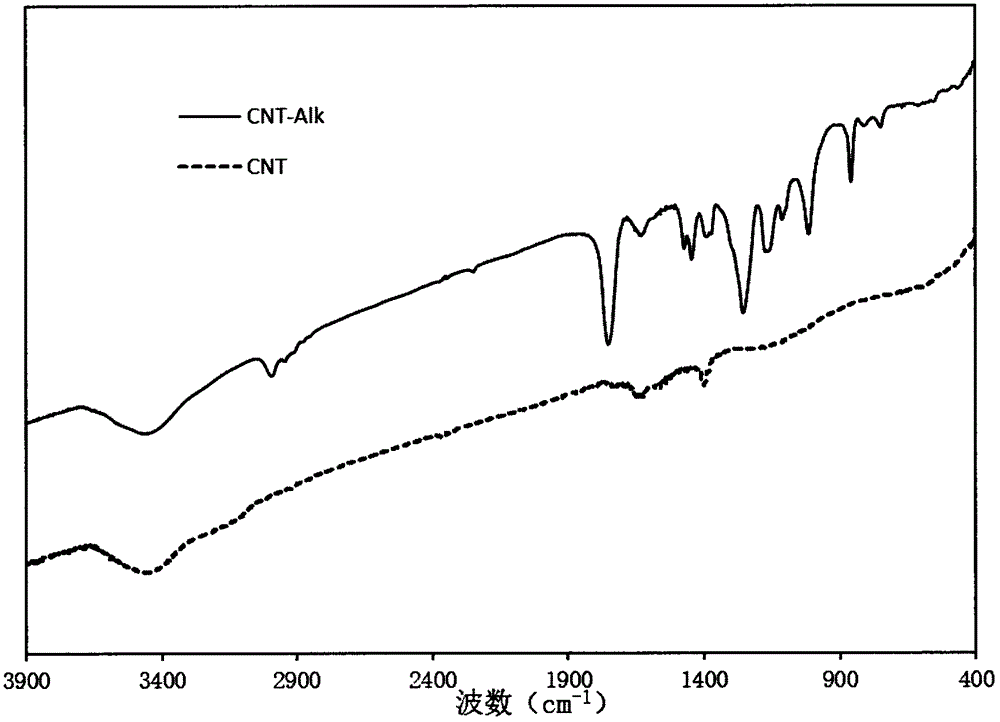

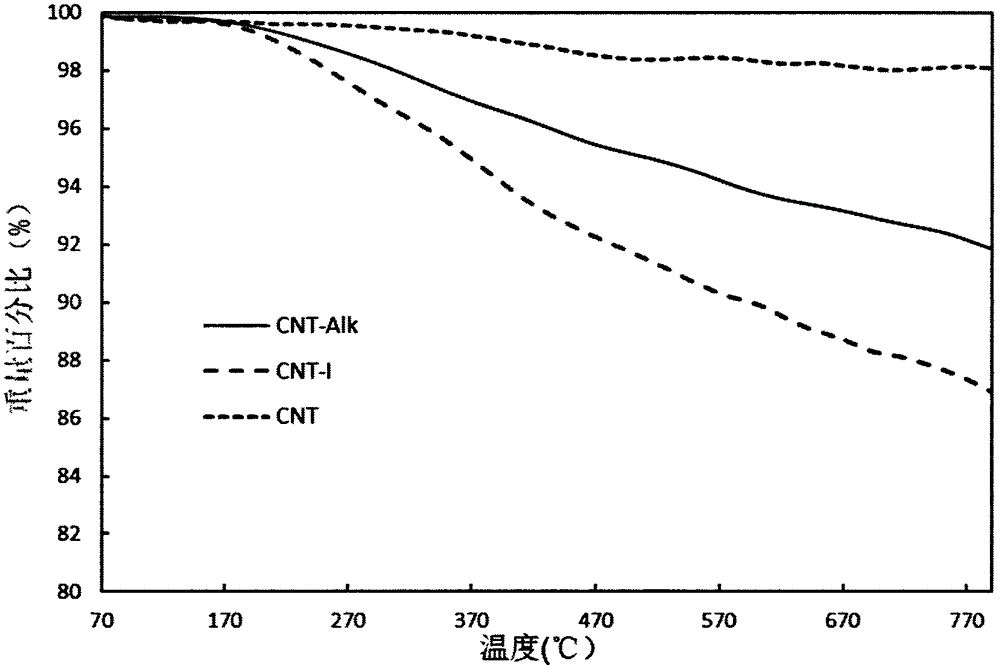

[0029] Example 1: Add 60mg of multi-walled carbon nanotubes and 4.38g of p-iodoaniline into a reaction vessel with a reflux device, and slowly add 3.33ml of isoamyl nitrite under the condition of no solvent and under the protection of nitrogen , Heated to 65°C, stirred and refluxed for 5h. Dilute with N, N-dimethylformamide, filter with suction and wash repeatedly until the filtrate is colorless, and then obtain iodine-modified carbon nanotubes, take 10 mg of carbon nanotubes after vacuum drying, and perform thermogravimetric analysis and characterization, as shown in figure 1 shown. Take 17 mg of iodine-modified carbon nanotubes obtained in the above steps and ultrasonically disperse them in 5 ml of tetrahydrofuran solution, add them into a Schlenk tube protected by anhydrous and oxygen-free nitrogen, add 0.003 ml of triethylamine, 4 mg of bis (Triphenylphosphine)palladium dichloride, 0.03ml trimethylsilylacetylene, stirred at room temperature for 8h, after the reaction, suc...

Embodiment 2

[0030] Example 2: Add 60mg of multi-walled carbon nanotubes and 3.44g of p-bromoaniline into a reaction vessel with a reflux device, and slowly add 3.33ml of isoamyl nitrite under the condition of no solvent under the protection of nitrogen , Heated to 65°C, stirred and refluxed for 5h. Dilute with tetrahydrofuran, filter with suction and wash repeatedly until the filtrate is colorless to obtain bromine-modified carbon nanotubes. Ultrasonically disperse the washed carbon nanotubes in 15ml of tetrahydrofuran solution, add anhydrous and oxygen-free nitrogen protected Schlenk In the Schlenk tube, add 0.003ml triethylamine, 4mg bis(triphenylphosphine) palladium dichloride, 0.03ml trimethylsilylacetylene drop by drop, stir at room temperature for 8h, after the reaction is over, suction filter And washed repeatedly with tetrahydrofuran until the filtrate was colorless. A silane deprotection reagent was added to wash with 2 mol / l ammonium chloride reagent, suction filtered and vacuu...

Embodiment 3

[0031] Example 3: Add 60mg of multi-walled carbon nanotubes and 2.29g of p-iodoaniline into a reaction vessel with a reflux device, and slowly add 2.22ml of isoamyl nitrite under the condition of no solvent and under the protection of argon Ester, heated to 65 ° C, stirred and refluxed for 7h. Dilute with tetrahydrofuran, filter with suction and wash repeatedly until the filtrate is colorless to obtain iodine-modified carbon nanotubes. Ultrasonically disperse the washed carbon nanotubes in 15ml of tetrahydrofuran solution, add anhydrous and oxygen-free nitrogen protected Schlenk In the Schlenk tube, add 0.003ml triethylamine, 4mg bis(triphenylphosphine) palladium dichloride, 0.03ml trimethylsilylacetylene drop by drop, stir at room temperature for 8h, after the reaction is over, suction filter And washed repeatedly with tetrahydrofuran until the filtrate was colorless. Add 1 mol / l sodium hydroxide methanol solution of silane deprotection reagent to wash, suction filter and va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com