GaN-based heterojunction schottky diode device and preparing method thereof

A Schottky diode and heterojunction technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of single process technology, decline, and complicated operation process, and achieve simple process and good repeatability , the effect of large conduction current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

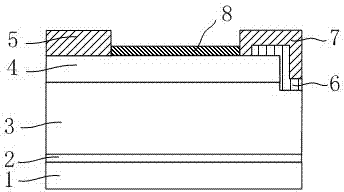

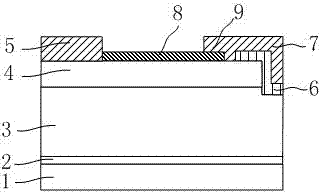

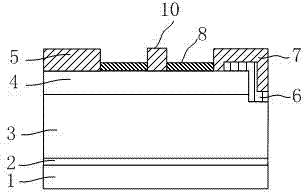

[0053] The fabrication method of the above-mentioned GaN-based heterojunction Schottky diode device is as follows: Figure 4A -F shows, including the following steps:

[0054] ① Using metal-organic chemical vapor deposition (MOCVD) or molecular beam epitaxy (MBE), sequentially grow stress buffer layer 2, high-resistance GaN layer 3 and heterostructure barrier on Si substrate or SiC substrate or sapphire substrate 1 layer 4; as Figure 4A shown;

[0055] ② After the device isolation is completed, dry etching is used to etch the groove 11 in the anode region on the surface of the GaN layer 3 and the heterostructure barrier layer 4, revealing that the groove 11 is composed of the surface of the groove and the surface of the heterostructure barrier layer. the contact surface; such as Figure 4B shown;

[0056] ③Use photolithography technology to open a window at the ohmic contact area of the cathode area, and then vapor-deposit the ohmic contact metal layer 5; Figure 4C sh...

Embodiment 2

[0063] Example 3

Embodiment 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com