Degradable electric-insulation material

An insulating material and electric power technology, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of deteriorating human living environment, improper application of insulating materials, secondary environmental pollution, etc. Effects of stability and flame retardant properties, high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

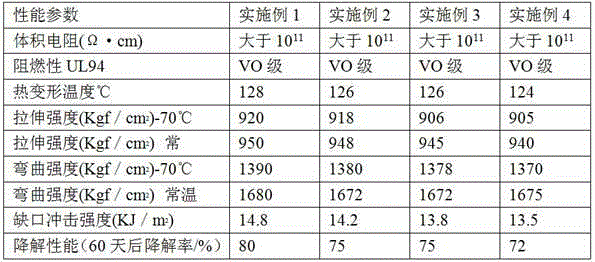

Examples

Embodiment 1

[0017] A degradable electrical insulation material, which is made of the following raw materials: L-polylactic acid 55Kg, bacterial cellulose (1mm in length) 30Kg, cross-linked polyethylene 15Kg, polyvinyl chloride 25Kg, decabromodiphenyl ether 5Kg, decabromodiphenylethane 10, hydroxyethyl cellulose 8Kg, glass fiber 22Kg, starch ether 18Kg, polycarbonate 25Kg, polyvinyl alcohol 12Kg, ethylene propylene rubber 24Kg, ethylene propylene rubber 24Kg, silane coupling agent 10Kg .

[0018] Take the above-mentioned raw materials according to the weight Kg, add each raw material in the centrifuge in turn, and stir for 8 minutes under the condition of 850 r / min. After mixing evenly, enter the twin-screw extruder to extrude into a molten state, and the temperature is controlled at 200°C, then use the injection machine to quickly inject the melt into the mold, the mold is closed and cooled to shape, after the mold is opened, the finished product enters the auxiliary mold, and the side is...

Embodiment 2

[0020] The degradable electrical insulating material of the present embodiment is made of the following raw materials: 50Kg of L-polylactic acid, 30Kg of bacterial cellulose (2mm in length), 10Kg of cross-linked polyethylene, 20Kg of polytetrafluoroethylene, chlorinated Paraffin wax 5Kg, decabromodiphenylethane 5, hydroxyethyl cellulose 5Kg, glass fiber 20Kg, starch ether 10Kg, polycarbonate 20Kg, polyvinyl alcohol 10Kg, ethylene propylene rubber 20Kg, silane coupling agent 5Kg.

[0021] The preparation method of the degradable electrical insulating material of this embodiment is characterized in that: Weigh the above-mentioned raw materials according to the weight Kg, add each raw material to the centrifuge in turn, stir for 5 minutes under the condition of 1000r / min, and mix well , enter the twin-screw extruder and extrude into a molten state, the temperature is controlled at 180°C, and then the molten body is quickly injected into the mold with an injection machine, the mold...

Embodiment 3

[0023] The degradable electric insulating material of present embodiment, it is made of following raw material: L-polylactic acid 60Kg, bacterial cellulose 40Kg, cross-linked polyethylene 20Kg, chlorosulfonated polyethylene 30Kg, chlorinated paraffin 10Kg, ten Bromodiphenylethane 20, hydroxyethyl cellulose 15Kg, glass fiber 30Kg, starch ether 20Kg, polycarbonate 30Kg, polyvinyl alcohol 15Kg, ethylene propylene rubber 25Kg, silane coupling agent 10Kg.

[0024] The preparation method of the degradable electrical insulation material of this embodiment is characterized in that: weigh the above-mentioned raw materials according to the weight Kg, add each raw material to the centrifuge in turn, stir for 6 minutes under the condition of 900r / min, and mix evenly , enter the twin-screw extruder to extrude into a molten state, the temperature is controlled at 185°C, and then the molten body is quickly injected into the mold with an injection machine, the mold is closed and cooled to shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com