Rare earth silicate coating and method for preparing coating on surface of C/SiC composite material

A rare earth silicate and coating technology, applied in the direction of coating, etc., can solve the problems of limited shape of components, high preparation temperature, complicated preparation process, etc., achieve low preparation temperature, simple principle, and realize large-scale industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: raw material preparation: yttrium oxide powder (average particle diameter 3 microns) wt30%, solvent ethanol and butanone each wt30%, dispersant triethyl phosphate wt2%, binding agent polyvinyl butyral wt3%, remove Each wt2% of foaming agent n-butyl alcohol and ethylene glycol, each wt3% of plasticizer glycerol and dioctyl phthalate;

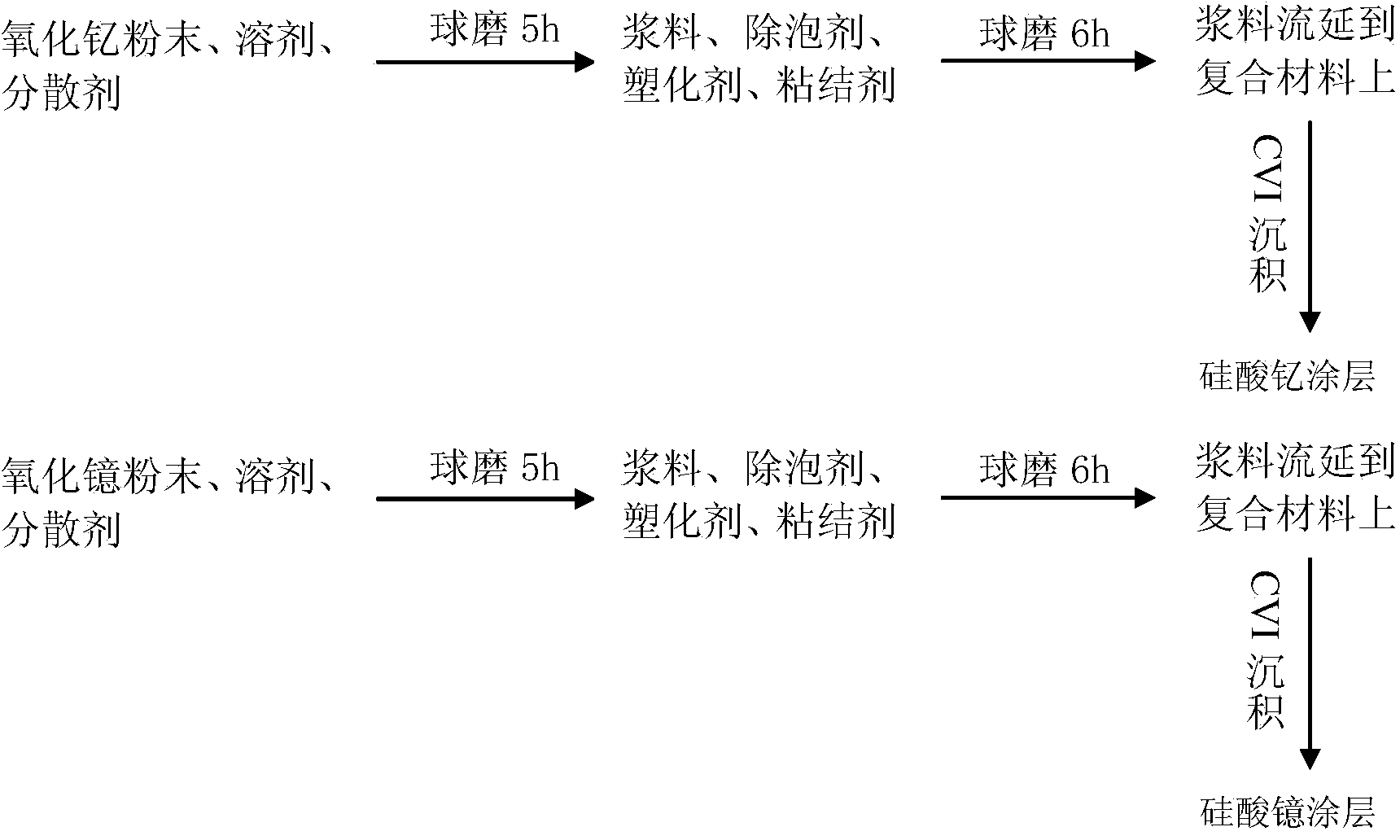

[0032] Step 2: Casting method to obtain the initial coating of the composite material: the specific process is:

[0033]a. Mix the yttrium oxide powder, solvent ethanol and methyl ethyl ketone, and dispersant triethyl phosphate in the raw materials of step 1 according to the proportioning ratio and carry out ball milling. The ball milling time is 5h, and the ball milling drum speed is 120r / min;

[0034] b. Take out the aforementioned ball-milled slurry, and then add plasticizer glycerol and dioctyl phthalate, defoamer n-butanol and ethylene glycol, and binder polyvinyl butyral according to the ratio. Put into the drum type ball mi...

Embodiment 2

[0039] Step 1: raw material preparation: yttrium oxide powder (average particle diameter 3 microns) wt30%, solvent ethanol and butanone each wt30%, dispersant triethyl phosphate wt2%, binding agent polyvinyl butyral wt3%, remove Each wt2% of foaming agent n-butyl alcohol and ethylene glycol, each wt3% of plasticizer glycerol and dioctyl phthalate;

[0040] Step 2: Casting method to obtain the initial coating of the composite material: the specific process is:

[0041] a. Mix the yttrium oxide powder, solvent ethanol and methyl ethyl ketone, and dispersant triethyl phosphate in the raw materials of step 1 according to the proportioning ratio and carry out ball milling. The ball milling time is 5h, and the ball milling drum speed is 120r / min;

[0042] b. Take out the aforementioned ball-milled slurry, and then add plasticizer glycerol and dioctyl phthalate, defoamer n-butanol and ethylene glycol, and binder polyvinyl butyral according to the ratio. Put into the drum type ball m...

Embodiment 3

[0047] Step 1: raw material preparation: yttrium oxide powder (average particle diameter 3 microns) wt30%, solvent ethanol and butanone each wt30%, dispersant triethyl phosphate wt2%, binding agent polyvinyl butyral wt3%, remove Each wt2% of foaming agent n-butyl alcohol and ethylene glycol, each wt3% of plasticizer glycerol and dioctyl phthalate;

[0048] Step 2: Casting method to obtain the initial coating of the composite material: the specific process is:

[0049] a. Mix the yttrium oxide powder, solvent ethanol and methyl ethyl ketone, and dispersant triethyl phosphate in the raw materials of step 1 according to the proportioning ratio and carry out ball milling. The ball milling time is 5h, and the ball milling drum speed is 120r / min;

[0050] b. Take out the aforementioned ball-milled slurry, and then add plasticizer glycerol and dioctyl phthalate, defoamer n-butanol and ethylene glycol, and binder polyvinyl butyral according to the ratio. Put into the drum type ball m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com