Freshwater cyprinidae fish mixed feed and preparation method thereof

A compound feed, carp family technology, applied in the direction of animal feed, animal feed, application, etc., can solve the heat loss of vitamins and materials that are not resistant to high temperature, reduce the utilization rate of fish meal, soybean protein, and the high processing cost of the puffing process. The effect of disease resistance, inhibition of cyanobacteria growth, and reduction of environmental water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

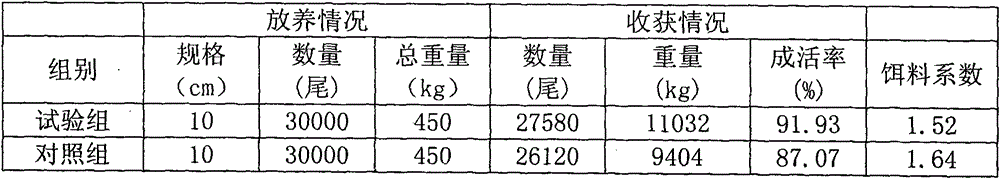

Examples

Embodiment 1

[0024] Embodiment 1: Prepare compound feed according to the following steps:

[0025] (1) Weigh raw materials according to mass percentage: fish meal: 5%; soybean meal: 15%; cotton meal: 17%; rapeseed meal: 28%; flour: 15%; bran: 6%; 1%; calcium dihydrogen phosphate: 1%; multivitamin premix: 0.2%; multimineral element premix: 0.5%; 50% choline chloride: 0.1%; zeolite powder 1.15%. Phytase premix: 0.02%; Lactobacillus premix: 0.03%;

[0026] (2) Raw materials such as fish meal, soybean meal, cotton meal, rapeseed and rice bran are crushed once, and 100% of the fineness is passed through a 20-mesh sieve, and 80% of the fineness is passed through a 40-mesh sieve.

[0027] (3) Mix raw materials such as pulverized fish meal, soybean meal, cotton meal, cabbage and rice bran with flour, calcium dihydrogen phosphate, choline chloride, zeolite powder, etc., and the mixing coefficient of variation is less than 10%.

[0028] (4) After the mixture is conditioned for 1 to 2 minutes throu...

Embodiment 2

[0034] (1) Weigh raw materials according to mass percentage: fish meal: 12%; soybean meal: 20%; cotton meal: 15%; rapeseed meal: 20%; flour: 15%; bran: 5%; 1.5%; calcium dihydrogen phosphate: 1.2%; multivitamin premix: 0.2%; multimineral element premix: 0.5%; 50% choline chloride: 0.15%; zeolite powder 1.4%. Phytase premix: 0.02%; Lactobacillus premix: 0.03%;

[0035] (2) Raw materials such as fish meal, soybean meal, cotton meal, rapeseed and rice bran are crushed once, and 100% of the fineness is passed through a 20-mesh sieve, and 80% of the fineness is passed through a 40-mesh sieve.

[0036] (3) Mix raw materials such as pulverized fish meal, soybean meal, cotton meal, cabbage and rice bran with flour, calcium dihydrogen phosphate, choline chloride, zeolite powder, etc., and the mixing coefficient of variation is less than 10%.

[0037] (4) After the mixture is conditioned for 1 to 2 minutes through a conditioner fed with water vapor, it enters the extruding granulator t...

Embodiment 3

[0043] (1) Weigh raw materials according to mass percentage: fish meal: 20%; soybean meal: 25%; cotton meal: 10%; rapeseed meal: 15%; flour: 15%; bran: 3%; 2%; calcium dihydrogen phosphate: 1.5%; multivitamin premix: 0.2%; multimineral element premix: 0.5%; 50% choline chloride: 0.2%; zeolite powder 1.55%. Phytase premix: 0.01%; Lactobacillus premix: 0.04%;

[0044] (2) Raw materials such as fish meal, soybean meal, cotton meal, rapeseed and rice bran are crushed once, and 100% of the fineness is passed through a 20-mesh sieve, and 80% of the fineness is passed through a 40-mesh sieve.

[0045] (3) Mix raw materials such as pulverized fish meal, soybean meal, cotton meal, cabbage and rice bran with flour, calcium dihydrogen phosphate, choline chloride, zeolite powder, etc., and the mixing coefficient of variation is less than 10%.

[0046] (4) After the mixture is conditioned for 1 to 2 minutes through a conditioner fed with water vapor, it enters the extruding granulator to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com