Method and device for producing mineral wool by matching molten-state blast furnace slag with mine tailings

A technology for blast furnace slag and mine tailings, which is applied in the field of producing mineral wool from molten blast furnace slag and mine tailings, can solve the problem of not meeting the requirements of mineral wool for external insulation of external walls, wasting a large amount of sensible heat of molten blast furnace slag, and producing products. Poor quality and other problems, to avoid low acidity coefficient, reduce operating costs, and reduce production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

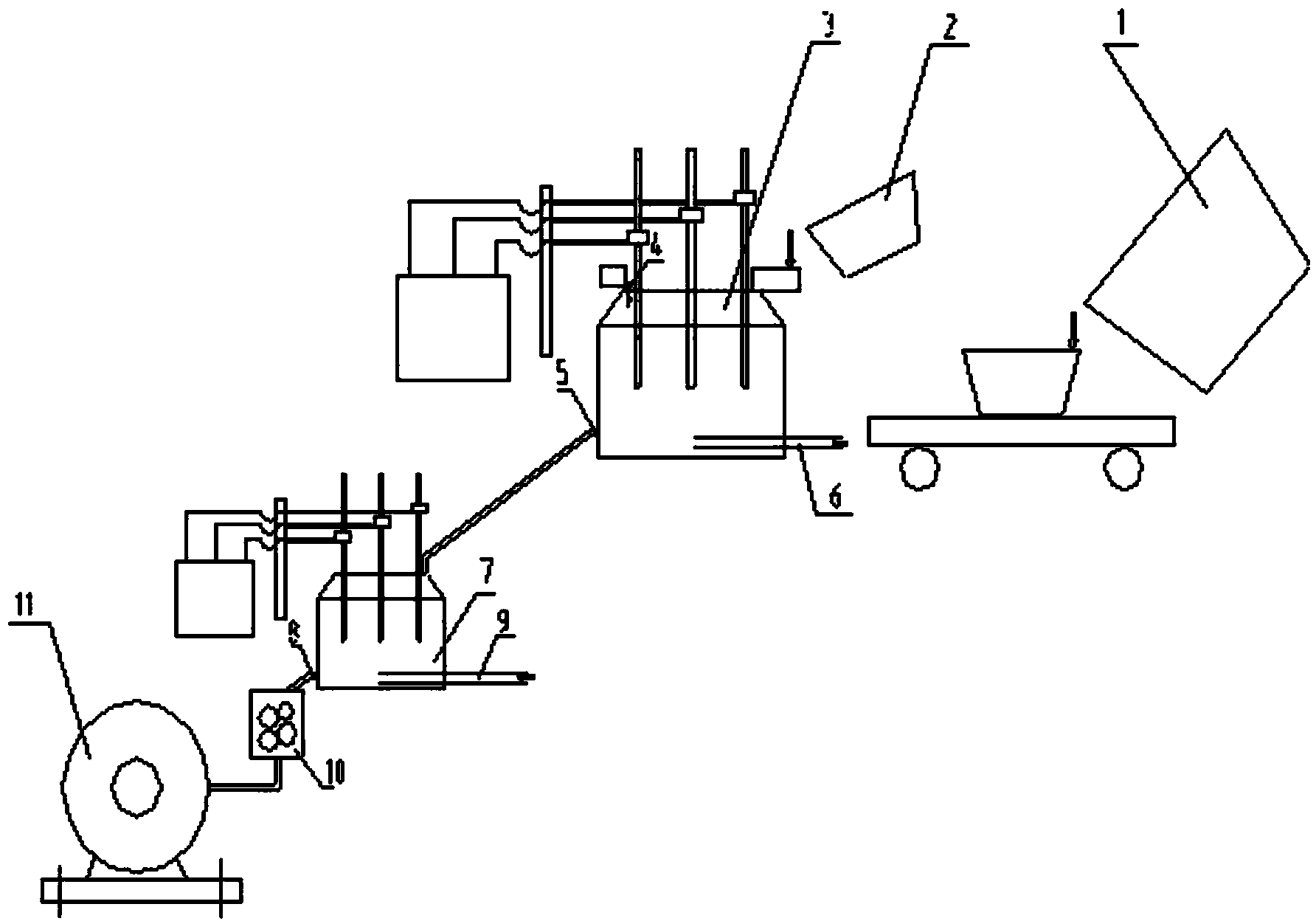

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0028] See figure 1 , is a schematic process flow diagram of the present invention, the present invention is equipped with molten blast furnace slag and mine tailings to produce mineral wool method, with molten blast furnace slag as raw material, mine tailings as conditioning agent, comprising the following steps:

[0029] 1) The molten blast furnace slag is transported from the blast furnace to the mineral wool production line with the thermal insulation slag tank 1, poured into the 5t small slag tank 2 in batches, and then the molten blast furnace slag in the small slag tank 2 is poured into the electric furnace 1 3, and at the same time Put the mine tailings into the electric furnace one 3;

[0030] 2) In the electric furnace one 3, the temperature of the molten pool is controlled between 1200°C and 1600°C, and nitrogen is injected at the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com