Microbial preparation for improving meat quality of Yanbian yellow cattle, and preparation method of microbial preparation

A microbial preparation, the technology of Yanbian cattle, applied in the direction of animal feed, animal feed, application, etc., can solve the problem that the excellent characteristics and meat production capacity cannot be fully exerted, the nutritional supply and growth needs of the cattle cannot be guaranteed, and the cattle feeding Problems such as limited knowledge of personnel, to achieve the effect of simple and easy operation, enhanced quality, and improved bacterial protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

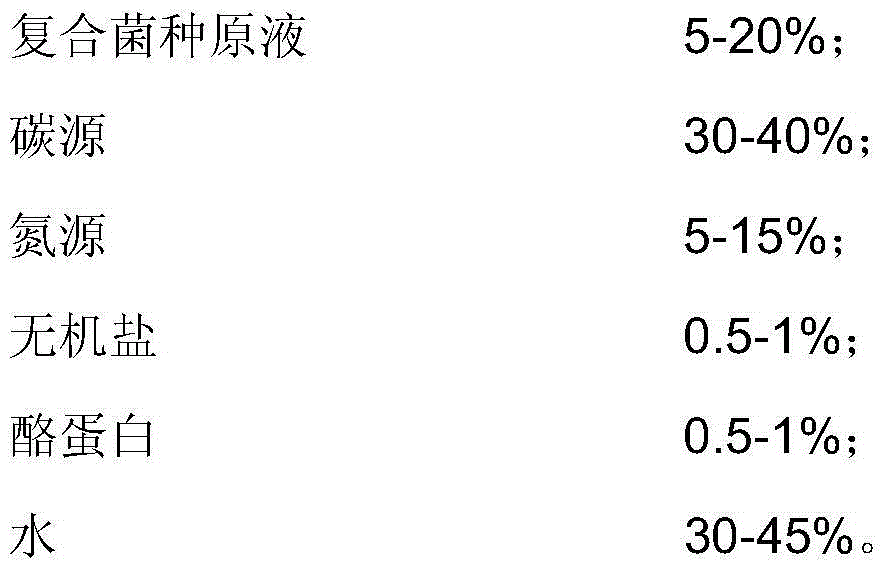

[0055] The second aspect of the present invention provides a kind of preparation method of microbial preparation as described in the first aspect, it is characterized in that, described preparation method comprises:

[0056] Step 1: Mix the stock solution of the composite strain, carbon source, nitrogen source, inorganic salt, casein, and water into a closed tank according to the weight ratio, and then place the closed tank in a fermenter for fermentation for 4-6 days;

[0057] Step 2: After the fermentation is finished, dry the mixture in the airtight tank at 40-45°C for 8-10 hours, then pulverize and sieve, and then pulverize and sieve the coarse material;

[0058] Step 3: Put the sieved product into a packaging bag, transfer it to the finished product warehouse for orderly stacking, and finally notify the quality control department to take a sample for testing, and obtain the microbial preparation after passing the test.

[0059] According to the technical solution of the p...

Embodiment 1

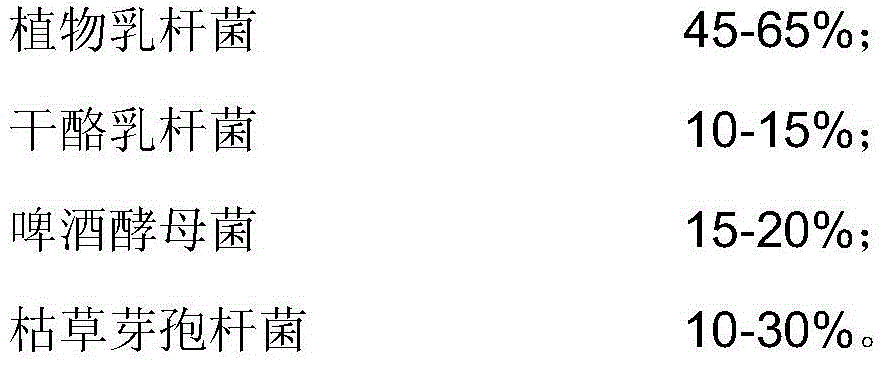

[0061] (1) Preparation of composite microbial agent

[0062] Step 1: Inoculate the purchased Lactobacillus plantarum, Lactobacillus casei, Bacillus subtilis and Saccharomyces cerevisiae respectively in the broth medium, add 0.5% casein at the same time, and cultivate at 35°C for 22 hours; then inoculate Lactobacillus plantarum and Lactobacillus casei were respectively inoculated in lactic acid bacteria medium, Bacillus subtilis inoculated in nutrient agar medium, and Saccharomyces cerevisiae inoculated in McFarland agar medium, and streak culture was carried out to select the strains with fast growth and obvious characteristics Each single colony of each single colony was obtained as a single strain: Lactobacillus plantarum, Lactobacillus casei, Bacillus subtilis and Saccharomyces cerevisiae, which were preserved in the laboratory;

[0063] Step 2: Cultivation of single strains: transfer the obtained single strains into eggplant bottles equipped with nutrient agar medium, and ...

Embodiment 2

[0072] (1) The preparation of composite bacterial agent is the same as in Example 1

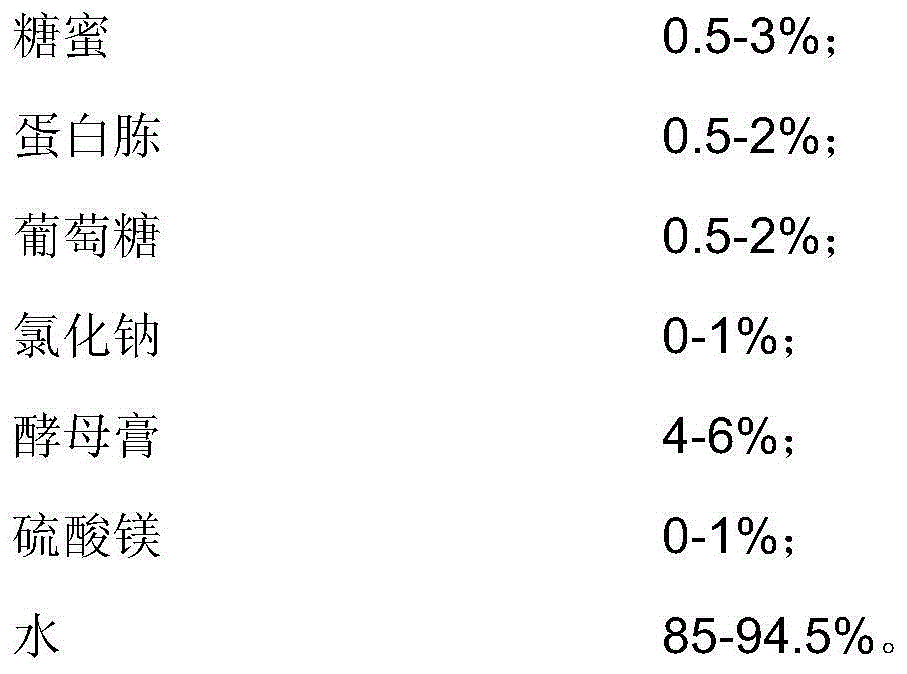

[0073] (2) Preparation of composite strain stock solution

[0074] The compound bacteria agent is added to the composite bacteria composed of molasses 3%, peptone 0.8%, glucose 2%, sodium chloride 0.8%, yeast extract 3%, magnesium sulfate 0.01% and water 90.59% by weight percentage of 4%. In the culture medium, adjust the pH value to 7.0, put it into a container that has been sterilized at 121°C for 20 minutes and cooled to 35°C, and put the container in a fermenter for fermentation for 6 days to obtain the complex bacteria stock solution.

[0075] (3) Preparation of microbial preparations

[0076] Step 1: Mix the compound strain stock solution, carbon source, nitrogen source, inorganic salt, casein, and water with 10% compound strain stock liquid, 38% carbon source, 15% nitrogen source, 0.5% inorganic salt, and 1% casein %, water 35.5% by weight and mix them into a closed tank that has be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com