Preparation method for large area CdS thin film

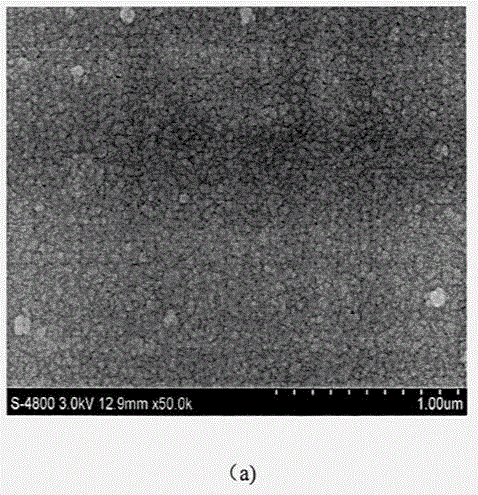

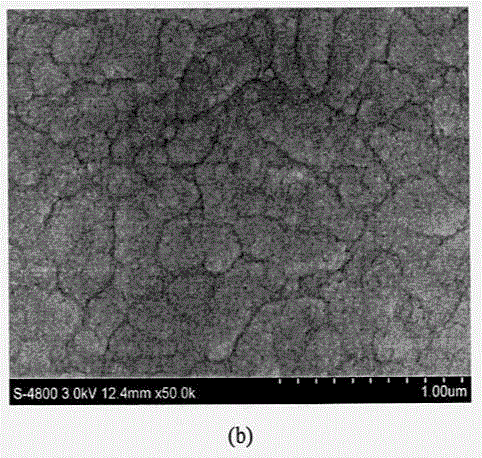

A thin-film preparation, large-area technology, applied in final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve the problems of difficult thin film growth, affecting thin film adsorption vacancies, thin thin film unevenness, etc., and achieve simple equipment. , The effect of dense film and fast reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

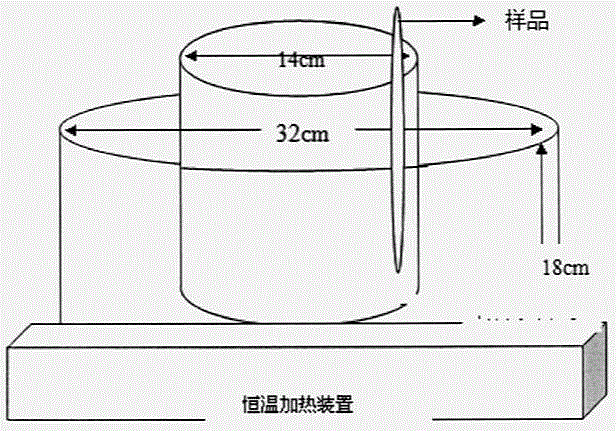

[0051] Based on the copper indium gallium selenide substrate, the chemical water bath method is used to prepare a large-area cadmium sulfide film under high ammonia conditions. The preparation steps are as follows:

[0052] Preparation of CIGS substrate: Firstly, the CIGS absorbing layer prepared on the glass substrate must be obtained.

[0053] 1) Cleaning of soda lemon glass

[0054] ① Soak a 3cm×3cm soda glass in heavy potassium hydroxide solution (a solution made of 300 grams of potassium hydroxide and 3 liters of deionized water) for 2 hours; ② Put the rinsed soda glass in a concentration of 99.5 % acetone solution, put it into an ultrasonic cleaning machine for cleaning with an ultrasonic frequency of 50kHz and a time of 30min, which can be properly heated to 40°C; ③ Take the soda glass out of the acetone solution and rinse it with deionized water; ④ Clean the washed Soda-lemon glass substrates were cleaned with alcohol and dried with nitrogen.

[0055] 2) Preparation ...

Embodiment 2

[0067] Based on the copper indium gallium selenide substrate, the chemical water bath method is used to prepare a large-area cadmium sulfide film under high ammonia conditions. The preparation steps are as follows:

[0068] Preparation of CIGS substrate: Firstly, the CIGS absorbing layer prepared on the glass substrate must be obtained.

[0069] 1) Cleaning of soda lemon glass

[0070] ① Soak a 3cm×3cm soda glass in heavy potassium hydroxide solution (a solution made of 300 grams of potassium hydroxide and 3 liters of deionized water) for 2 hours; ② Put the rinsed soda glass in a concentration of 99.5 % acetone solution, put it into an ultrasonic cleaning machine for cleaning with an ultrasonic frequency of 50kHz and a time of 30min, which can be properly heated to 40°C: ③Take the soda glass out of the acetone solution and rinse it with deionized water: ④Wash the cleaned Soda-lemon glass substrates were cleaned with alcohol and dried with nitrogen.

[0071] 2) Preparation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com