C2 fraction gas-phase selective hydrogenation catalyst and preparation method and application thereof

A technology for selective hydrogenation and catalyst, which is applied in the fields of hydrogenation to hydrocarbon production, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. High activity and its selectivity, good dispersion, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

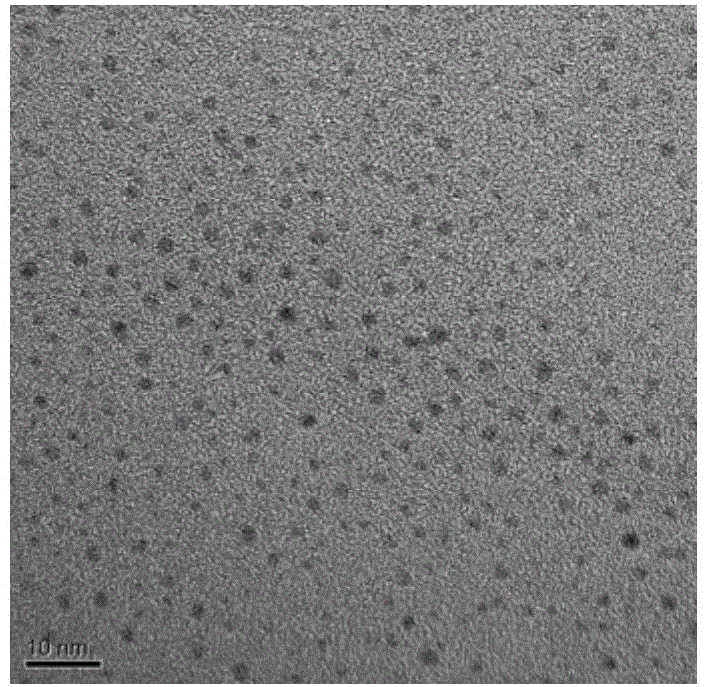

[0036] ① Pipette 50mgPd / mlPd(NO 3 ) 2 Solution 0.4ml, 300mgAg / ml AgNO 3 Solution 0.2ml, weigh polyvinylpyrrolidone (PVP) 800mg, dilute to 8g with deionized aqueous solution;

[0037] ②In a constant temperature water bath at 20°C, put 10g of non-ionic surfactant Brij30 and 10g of oil phase cyclohexane in a 100ml volumetric flask, stir for a certain period of time by magnetic force, then add ① into ② and stir for a certain period of time to obtain a W / O micro Lotion;

[0038] 3. Add reducing agent hydrazine hydrate, add in the microemulsion according to the mol ratio of metal salt and reducing agent in the water phase as 1:7, carry out reduction reaction, react for 8 hours;

[0039] ④ Weigh the tooth shape Al 2 o 3 Carrier 100g, impregnated with the microemulsion prepared above;

[0040] ⑤ Dried and calcined the carrier impregnated with the above-mentioned microemulsion to prepare the catalyst, and obtained the catalyst PM-1, wherein the Pd-Ag alloy content was 0.08% of th...

Embodiment 2

[0042] ① Pipette 50mgPd / mlPd(NO 3 ) 2 Solution 0.4ml, 300mgAg / ml AgNO 3 Solution 0.2ml, weigh polyvinylpyrrolidone (PVP) 800mg, dilute to 8g with deionized aqueous solution;

[0043] ②In a constant temperature water bath at 20°C, put 10g of non-ionic surfactant Brij30 and 10g of oil phase cyclohexane in a 100ml volumetric flask, stir for a certain period of time by magnetic force, then add ① into ② and stir for a certain period of time to obtain a W / O micro Lotion;

[0044] 3. Add reducing agent hydrazine hydrate, add in the microemulsion according to the mol ratio of metal salt and reducing agent in the water phase as 1:7, carry out reduction reaction, react for 8 hours;

[0045] ④ Weigh the tooth shape Al 2 o 3 Carrier 100g, impregnated with the microemulsion prepared above;

[0046] ⑤ drying and calcining the carrier impregnated with the above-mentioned microemulsion in ④ to obtain a semi-finished catalyst.

[0047] ⑥Respectively pipette 10mgLa / ml of La(NO 3 ) 3 So...

Embodiment 3

[0051] ① Pipette 0.5ml of 20mgPd / ml palladium oxalate solution, 0.5ml of 30mgAg / ml silver oxalate solution, weigh 1500mg of polyacrylamide (PAM), and dilute to 20g with deionized aqueous solution;

[0052] ②In a constant temperature water bath at 60°C, add 12g of anionic surfactant AOT and 8g of oil phase isooctane in a 100ml volumetric flask, stir for a certain period of time by magnetic force, then add ① into ② and stir for a certain period of time to obtain a W / O microemulsion ;

[0053] ③ Stir for a certain period of time, add the reducing agent sodium borohydride, add according to the molar ratio of the metal salt and the reducing agent in the water phase as 1:4, and carry out the reduction reaction for 4 hours;

[0054] ④ Weigh spherical TiO 2 Carrier 100g, impregnated with the microemulsion prepared above;

[0055] ⑤ Dried and calcined the carrier impregnated with the above-mentioned microemulsion to prepare the catalyst, and obtained the catalyst PM-3, wherein the Pd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com