Processing method of instant bullfrog

A processing method, bullfrog technology, applied in food processing, food preparation, food science, etc., can solve the problems affecting the processing and eating quality of bullfrog meat products, the difficulty of industrial production of products, and the impact on product yield, so as to reduce the loss of thawing, The effect of reducing the sterilization intensity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

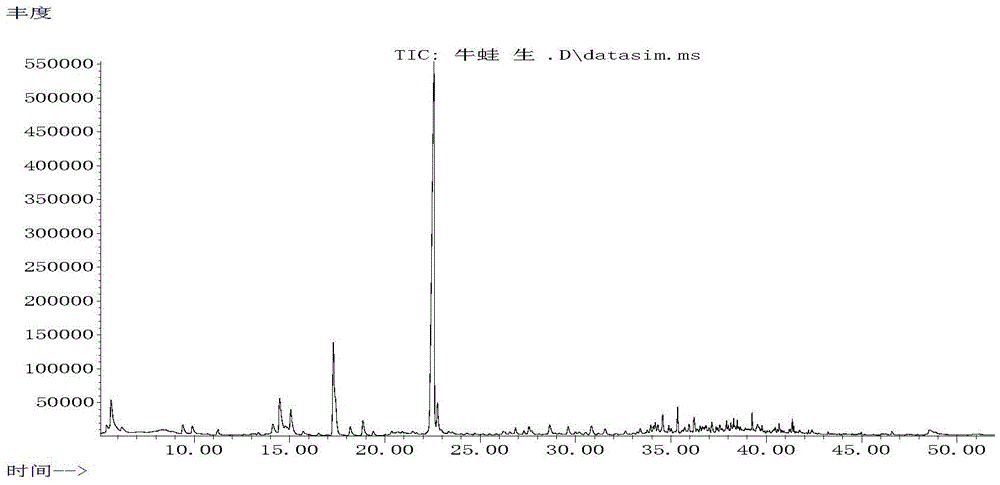

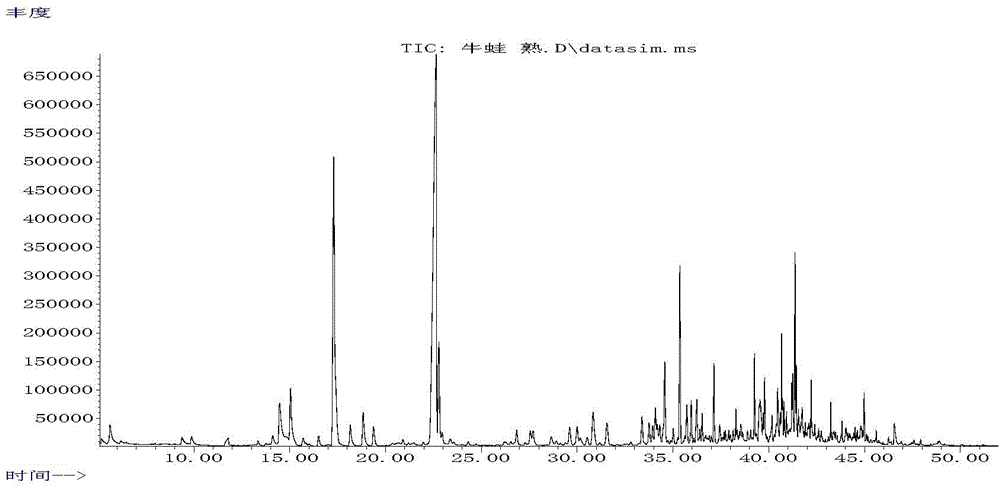

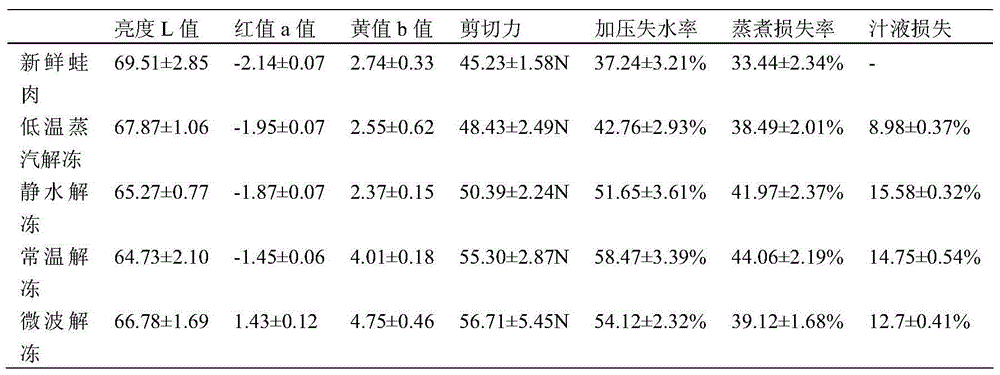

Image

Examples

Embodiment 1

[0032] (1) Select the frozen bullfrogs that have passed the hygienic inspection, and use low-temperature steam to thaw them, and thaw them at 1-5-1°C in a cycle of variable temperature. During the thawing process, decompression steam (6.6×10 2 -8.7×10 2 Pa), keep the relative humidity of the thawing chamber above 90%, thaw for 6 hours, and remove a small amount of exudate after thawing;

[0033] (2) add papain, 0.2% alkaline lipase, and 0.4% flavor protease by 0.2% of the bullfrog meat mass and process at 4°C for 25min;

[0034] (3) preparation pickling solution, get pepper powder 0.5%, white sugar 1.8%, soy sauce 4%, cooking wine 3%, monosodium glutamate 1%, ginger juice 3%, mirin 1.5%, yeast extract 1% by weight percentage of bullfrog meat quality %, ethyl maltol 0.2‰, salt 1.4%, to prepare a pickling solution;

[0035] (4) To prepare concentrated five-spice marinade, take 0.5 kg of chicken skeleton, 0.5 kg of pork bone, 50 g of ginger, and 4 kg of water, boil for 1-2 hour...

Embodiment 2

[0049] Embodiment 2 is the same as embodiment 1, the difference is,

[0050] (1) thawing at 3-10-3°C with variable temperature cycle, and decompression (7.58×10 2 -1.22×10 3 Pa) steam, thawed for 2h;

[0051] (2) add papain by 0.2% of the bullfrog meat mass, 0.25% alkaline lipase, and 0.2% flavor protease at 4°C for 20 min;

[0052] (3) preparation pickling solution, get pepper 1%, white sugar 2.5%, soy sauce 2%, cooking wine 1%, monosodium glutamate 1.2%, ginger juice 3.3%, mirin 2%, yeast extract 1.5% by weight percentage of bullfrog meat quality %, ethyl maltol 0.3‰, salt 2%, to prepare a pickling solution;

[0053] (5) After diluting the concentrated solution of step (4) by 1:5, add it to the pickling solution of step (3) in a weight ratio of 25%, to prepare a rolling solution;

[0054] (6) Mix the bullfrog after enzymatic hydrolysis in step (2) with the tumbling liquid prepared in step (4) according to a mass ratio of 1:1, and then tumbling for 3 hours at 4°C and a va...

Embodiment 3

[0065] Embodiment 3 is the same as Embodiment 1, and the difference is that

[0066] (1) thawing at 1-9-1°C with variable temperature cycle, and decompression (6.6×10 2 -1.14×10 32 Pa) steam, thawed for 6h;

[0067] (2) add papain, 0.1% alkaline lipase, and 0.2% flavor protease by 0.1% of the bullfrog meat mass and treat at 4°C for 20min;

[0068] (3) prepare pickle liquid, get pepper 0.5%, white sugar 1%, soy sauce 4%, cooking wine 4%, monosodium glutamate 2%, ginger juice 4%, mirin 1%, yeast paste 0.5% by weight percentage of bullfrog meat quality %, ethyl maltol 0.3‰, salt 3%, to prepare a pickling solution;

[0069] (5) After diluting the concentrated solution of step (4) by 1:5, add it to the pickling solution of step (3) in a weight ratio of 20%, to prepare a rolling solution;

[0070] (6) Mix the bullfrog after enzymatic hydrolysis in step (2) with the tumbling solution prepared in step (4) at a mass ratio of 1:1.2, and then tumbling for 2.5 hours at 4°C and a vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com