Composite binding agent diamond-impregnated wheel and manufacturing method thereof

A technology of composite binder and production method, which is applied in the direction of abrasive materials, grinding devices, manufacturing tools, etc., can solve the problems of poor heat resistance and short service life of grinding wheels, achieve high grinding efficiency, avoid blackening, and improve wear resistance. The effect of thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

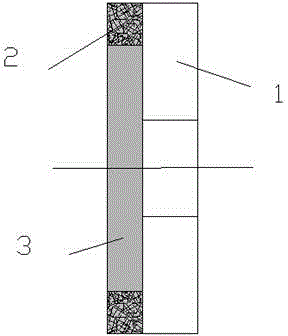

Image

Examples

Embodiment 1

[0036] Weigh 60 parts of polyimide resin powder, 20 parts of copper fiber with an aspect ratio of 18, 5 parts of copper powder, 7 parts of zinc oxide, 5 parts of iron red powder, 3 parts of calcium oxide powder, and fully mix in the mixer for 2 hours; Weigh 47 parts of diamond abrasive, 10 parts of green silicon carbide powder, 5 parts of furfuryl alcohol, and 38 parts of mixed composite binder powder, put them into a mixer and mix them thoroughly for 1 hour. Spread the liquid paraffin evenly on the molding surface of the mold, pour an appropriate amount of molding material and spread it out to make the thickness of the molding material uniform. Put the mold into a thermoforming machine, pressurize to 25 MPa, keep the pressure at 210°C for 1 hour, and cool naturally. Take out the mold and place it on a glass plate for demoulding; put the formed grinding wheel in an oven, keep it warm at 230°C for 1 hour, and cool naturally. After post-processing such as machining and sharpeni...

Embodiment 2

[0038] Weigh 42 parts of polyimide resin powder, 35 parts of copper fiber with an aspect ratio of 12, 10 parts of copper powder, 5 parts of zinc oxide powder, 5 parts of iron red powder, and 3 parts of calcium oxide powder, and put them into the mixer fully Mix for 2 hours; weigh 50 parts of diamond abrasive, 10 parts of green silicon carbide powder, 2 parts of furfuryl alcohol, and 38 parts of mixed composite binder powder, and fully mix in the mixer for 1 hour. Spread the zinc stearate release agent evenly on the molding surface of the mold, then pour an appropriate amount of molding material and spread it out to make the thickness of the molding material uniform. Put the mold into a thermoforming machine, pressurize to 30 MPa, keep the pressure at 215°C for 1 hour, and cool naturally. Take out the mold and place it on a glass plate for demoulding; put the formed grinding wheel in an oven, keep it warm at 230°C for 1 hour, and cool naturally. After post-processing such as m...

Embodiment 3

[0040] Weigh 30 parts of polyimide resin powder, 45 parts of copper fiber with an aspect ratio of 15, 10 parts of copper powder, 7 parts of zinc oxide powder, 6 parts of iron red powder, and 2 parts of calcium oxide powder, and put them into the mixer fully Mix for 2 hours; weigh 48 parts of diamond abrasive, 15 parts of green silicon carbide powder, 3 parts of furfuryl alcohol, and 34 parts of mixed composite binder powder, put them into the mixer and mix them for 1 hour. Spread liquid paraffin evenly on the molding surface of the mold, then pour an appropriate amount of molding material and spread it out to make the thickness of the molding material uniform. Put the mold into a thermoforming machine, pressurize to 40 MPa, keep the pressure at 215°C for 1 hour, and cool naturally. Take out the mold and place it on a glass plate for demoulding; put the formed grinding wheel in an oven, keep it warm at 230°C for 1 hour, and cool naturally. After post-processing such as machini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com