A method for removing micro or trace amounts of bromate in water using polymer fibers as carrier-loaded nano-iron

A polymer fiber and nano-iron technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of long reaction time of biodegradation method, reduced reduction reaction rate, and difficult recovery of nanoparticles. , to achieve the effect of technical feasibility, remarkable removal effect and excellent reaction kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

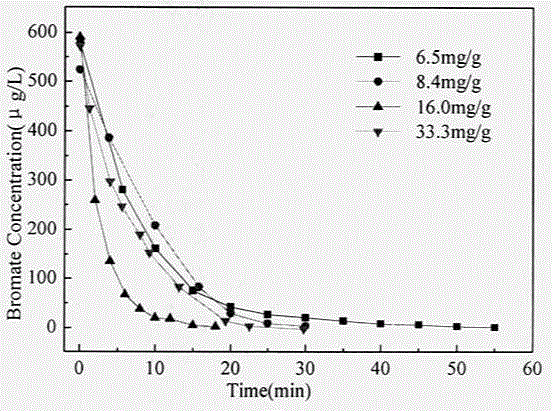

[0019] This example is to verify the fiber loading Fe 0 The effect of the amount on the bromate reduction reaction.

[0020] Use a 50ml Erlenmeyer flask equipped with a rubber stopper to add BrO with a concentration of 0.5mg / L 3 - The reaction solution is oscillated in a constant temperature water bath oscillator, the reaction temperature is 25°C, the rotation speed is 170r / min, and the reaction solution is passed through N 2 Deoxidation treatment.

[0021] Adjust the initial pH value of the reaction solution to 6.72, add 0.5g of fibers with different loadings of nanometer zero-valent iron, and the loadings of iron on the fiber surface are 6.5mg / g, 8.4mg / g, 16.4mg / g, and 33.3mg respectively / g, reaction time 1h. Detection of BrO by Dionex-1100 Ion Chromatography 3 - The final concentrations were 1.15μg / L, 1.30μg / L, 0.62μg / L, 1.5μg / L3 - And the content of dissolved total iron can reach the "Drinking Water Hygienic Standard" (GB5749-2006). Therefore, the present inventio...

Embodiment 2

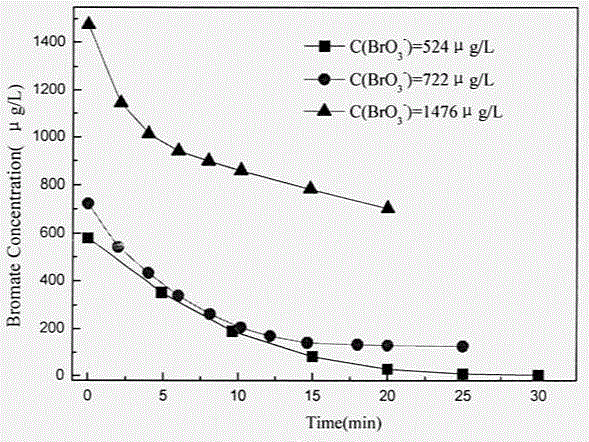

[0024] This example is to verify that different BrO 3 - Effect of initial concentration on bromate reduction reaction.

[0025] The configured concentration is 0.524mg / L, 0.722mg / L, 1.476mg / L BrO 3 - The reaction solution. Use three 50ml Erlenmeyer flasks equipped with rubber stoppers to add the three concentrations of BrO that have been configured. 3 - The reaction solution, the reaction solution is passed through N 2 Deoxidation treatment. Continuous oscillation was carried out in a constant temperature water bath oscillator, the reaction temperature was 25° C., and the rotation speed was 170 r / min.

[0026] The initial pH value of the reaction solution was adjusted to 6.7, 0.5 g of nanometer zero-valent iron fibers loaded in the reaction flask was added, the content of nanometer iron on the fiber surface was 8.4 mg / g, and the reaction time was 1.5 hours. Detection of BrO by Dionex-1100 Ion Chromatography 3 - The concentrations were 3.84μg / L, 9.57μg / L, 10.2μg / L≤10μ...

Embodiment 3

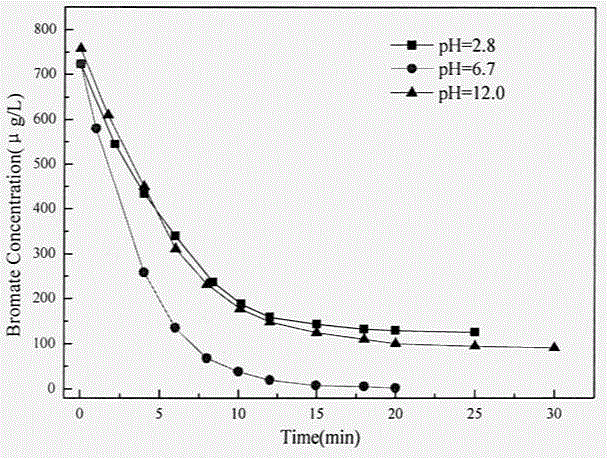

[0029] This example is to verify the influence of different initial solution pH values on bromate reduction reaction.

[0030] Use a 50ml Erlenmeyer flask equipped with a rubber stopper to add BrO with a concentration of 0.5mg / L 3 - The reaction solution was continuously oscillated in a constant temperature water bath oscillator, the reaction temperature was 25°C, the rotation speed was 170r / min, and the reaction solution was passed through N 2 Deoxidation treatment.

[0031] The initial pH values of the reaction solution were adjusted to 2.8, 6.7, and 12.0, respectively, and 0.5 g of nanometer zero-valent iron fibers were added to the reaction flask. The content of nanometer iron on the fiber surface was 8.4 mg / g, and the reaction time was 1.5 hours. Detection of BrO by Dionex-1100 Ion Chromatography 3 - The concentrations were 102μg / L, 0.56μg / L3 - And the content of dissolved total iron in the neutral range can meet the requirements of "Drinking Water Hygienic Standar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com