Treatment method of gold smelting plant high-salt wastewater hard to treat and containing ammonia and nitrogen

A treatment method and difficult-to-treat technology, which is applied in chemical instruments and methods, metallurgical wastewater treatment, water/sewage multi-stage treatment, etc., can solve the problems of reducing the diffusion coefficient of oxidant and the treatment effect, so as to avoid complicated operating conditions and reduce Investment and processing cost, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

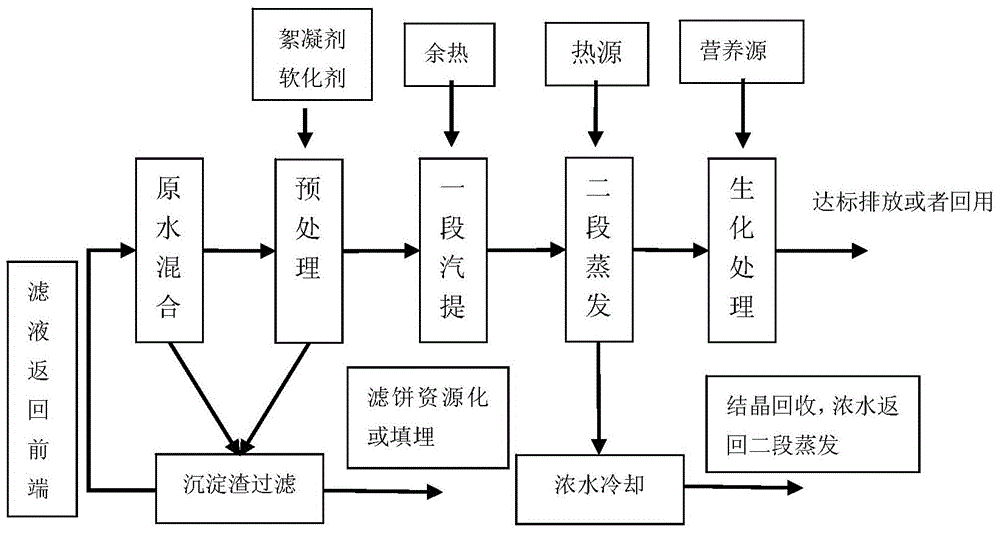

Image

Examples

Embodiment 1

[0033] After the waste water of each technological process is mixed, the water quality situation of the waste water to be treated is as follows: TDS=8.5wt%, [NH 3 -N]=8000mg·L -1 , [M n+ ]=230mg·L -1 ([M n+ ] is the total concentration of all heavy metals), [Ca 2+ ]=1200mg·L -1 ,COD=220mg·L -1 , pH=2.5.

[0034] Implementation steps:

[0035] (1) Adding Na to the above wastewater 2 CO 3 and Rhodococcus erythropolis microbial flocculant NOC-1, the dosage is 2000mg·L respectively -1 with 100mg·L -1 . After stirring and reacting for 0.5h, stand still and filter, and incinerate the obtained filter residue to realize sludge reduction and then landfill, and the filtrate and supernatant are mixed and pumped into the softening tank.

[0036] (2) Calculate according to the water quality and add a certain amount of sodium carbonate and sodium hydroxide in proportion to the softening tank, adjust the pH = 11.5, stir and react for 0.5h, then let stand, settle, filter, mix the ...

Embodiment 2

[0041] After the waste water of each technical process is mixed, the water quality situation of the waste water to be treated is as follows: TDS=10.2wt%, [NH 3 -N]=6000mg·L -1 , [M n+ ]=200mg·L -1 ([M n+ ] is the total concentration of all heavy metals), [Ca 2+ ]=1100mg·L -1 ,COD=375mg·L -1 ,pH=3.5

[0042] Implementation steps:

[0043] (1) Adding Na to the above wastewater 2 CO 3 and Rhodococcus erythropolis microbial flocculant NOC-1, the dosage is 3000mg·L respectively -1 with 150mg·L -1 . After stirring and reacting for 1 hour, stand still and filter, and incinerate the obtained filter residue to realize sludge reduction, and then landfill it. The filtrate and supernatant are mixed and pumped into the softening tank.

[0044] (2) Calculate according to the water quality and add a certain amount of sodium carbonate and sodium hydroxide in proportion to the softening tank, adjust the pH = 11.5, stir and react for 0.5h, then let stand, settle, filter, mix the fil...

Embodiment 3

[0049] After the waste water of each technical process is mixed, the water quality situation of the waste water to be treated is as follows: TDS=12.3wt%, [NH 3 -N]=5000mg·L -1 , [M n+ ]=180mg·L -1 ([M n+ ] is the total concentration of all heavy metals), [Ca 2+ ]=1200mg·L -1 ,COD=500mg·L -1 ,pH=4.0

[0050] Implementation steps:

[0051] (1) Adding Na to the above wastewater 2 CO 3 and Rhodococcus microbial flocculant NOC-1, the dosage is 4000mg L -1 with 200mg·L -1 . Stirring and reacting for 1.5 hours, let it stand still, filter, incinerate the obtained filter residue to realize sludge reduction, and then landfill it. The filtrate and supernatant are mixed and pumped into the softening tank.

[0052] (2) Calculate according to the water quality and add a certain amount of sodium carbonate and sodium hydroxide in proportion to the softening tank, adjust the pH = 11.5, stir and react for 0.5h, then let stand, settle, filter, mix the filtrate and the supernatant and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com