Water soluble xanthophyll preparation technology

A technology for water-soluble lutein and preparation process, which is applied in the field of water-soluble lutein preparation technology, can solve the problems of reducing the content of all-trans isomers, affecting the quality of lutein, and difficulty in solvent recovery, so as to ensure water solubility, The effect of improving stability and avoiding secondary reprocessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

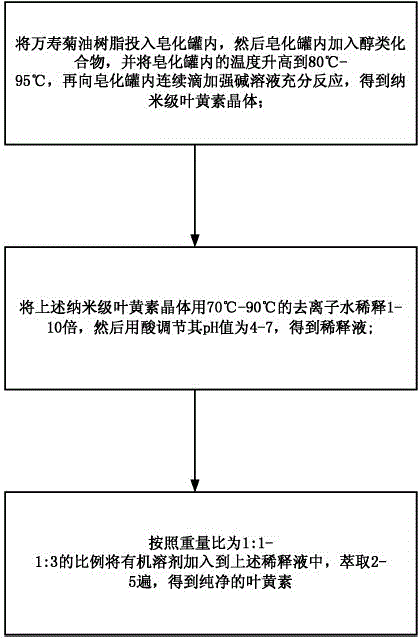

Method used

Image

Examples

Embodiment 1

[0044] Example 2

[0045] Take 50g of marigold oleoresin with a content of 145g / kg, put it into a saponification tank, add 7.5g of propylene glycol, raise the temperature to 85°C, and keep the stirring speed at 100rpm, continuously add 17ml of NaOH aqueous solution with a concentration of 10mol / L for 1 hour, After 4 hours of saponification, add 300g of deionized water at 85°C, add 102g of sulfuric acid with a mass concentration of 10%, to make the pH value 4.0, then add 1040g of 6# solvent oil for extraction, extract 4 times, and dilute the diluted solution after extraction , add 4.6g of natural VE and 5.7g of Span-80; dissolve 55g of soluble starch in 350g of deionized water at 80°C for 30 minutes, then add 20g of glucose to dissolve, cool to 45°C to obtain a diluted solution for use. The dilution and the wall material solution were mixed twice in a high-shear homogeneous emulsifier, and then water was removed by spray drying to finally obtain an aqueous solution lutein powde...

Embodiment 2

[0047] Take 150g of marigold oleoresin with a content of 100g / kg, put it into a saponification tank, add 7.5g of mannitol, raise the temperature to 95°C, and keep the stirring speed at 100rpm, and continuously add 51ml of NaOH aqueous solution with a concentration of 10mol / L for 1 hour After 4 hours of saponification time, add 150g of deionized water at 95°C, add 185g of phosphoric acid with a mass concentration of 10%, to make the pH value 6.0, then add 1200g of petroleum ether for extraction, extract 5 times, and add the diluent after extraction to 5.24g rosemary and 8.74g sucrose ester; dissolve 30g soluble starch in 90g deionized water at 80°C for 30 minutes, then add 18.5g β-cyclodextrin to dissolve, cool to 45°C to obtain a diluent for use. Mix the diluent and the wall material solution twice in a high-shear homogeneous emulsifier, and then remove water by spray drying to finally obtain an aqueous solution of lutein powder with a content of 152g / kg and a weight of 87.4g. ...

Embodiment 3

[0049] Of course, the above descriptions are not intended to limit the present invention, and the present invention is not limited to the above examples. Changes, modifications, additions or replacements made by those skilled in the art within the scope of the present invention shall also belong to the present invention. protection scope of the invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com