Adhesive mono-component addition silicone rubber adhesive and preparation method thereof

A one-component, addition-type technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems of reduced production efficiency, poor adhesion, impact, etc., to achieve good adhesion effect, the effect of good bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

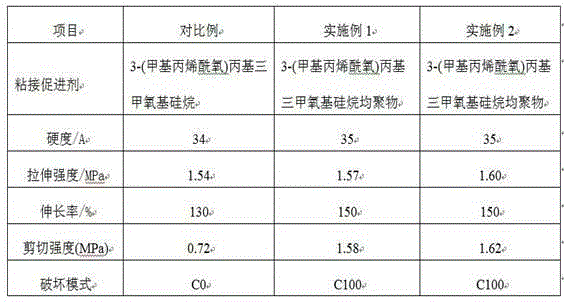

Embodiment 1

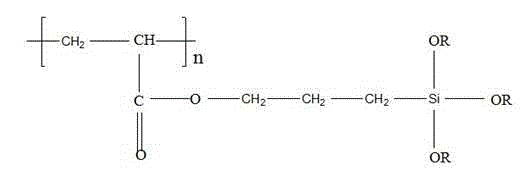

[0040] (1) Synthesis of adhesion promoter

[0041] The homopolymer of 3-(methacryloyloxy)propyltrimethoxysilane was synthesized by free radical solution polymerization, with dibenzoyl peroxide as the initiator, ethyl acetate as the solvent, and the mass fraction of the monomer 20%, and the initiator dibenzoyl peroxide consumption is 0.5% of the monomer consumption. The specific synthesis process is to add 80% ethyl acetate into a glass reaction vessel, stir under the protection of nitrogen atmosphere, heat up to about 78°C, and when reflux occurs, add the remaining 20% ethyl acetate that has been mixed in advance in a dropwise manner. Esters, 3-(methacryloyloxy)propyltrimethoxysilane, the dosage is a mixture of chain transfer agent tert-dodecyl mercaptan and dibenzoyl peroxide with an amount of 0.4% of the monomer, and the dropping time is controlled at about 60 minutes After the dropwise addition is completed, continue the heat preservation reaction for 7 hours, then cool ...

Embodiment 2

[0045] (1) Synthesis of adhesion promoter

[0046] The homopolymer of 3-(methacryloyloxy)propyltrimethoxysilane was synthesized by free radical solution polymerization, with dibenzoyl peroxide as the initiator, ethyl acetate as the solvent, and the mass fraction of the monomer 20%, and the initiator dibenzoyl peroxide consumption is 0.5% of the monomer consumption. The specific synthesis process is to add 80% ethyl acetate into a glass reaction vessel, stir under the protection of nitrogen atmosphere, heat up to about 78°C, and when reflux occurs, add the remaining 20% ethyl acetate that has been mixed in advance in a dropwise manner. Esters, 3-(methacryloyloxy)propyltrimethoxysilane, the dosage is a mixture of chain transfer agent tert-dodecyl mercaptan and dibenzoyl peroxide with an amount of 0.1% of the monomer, and the dropping time is controlled at about 60 minutes After the dropwise addition is completed, continue the heat preservation reaction for 7 hours, then cool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com