Special surface treating agent for neodymium iron boron and application method of special surface treating agent

A surface treatment agent, NdFeB technology, applied in the coating process of metal materials, etc., can solve the problems of complex process, affecting the performance and life of NdFeB magnetic materials, poor corrosion resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

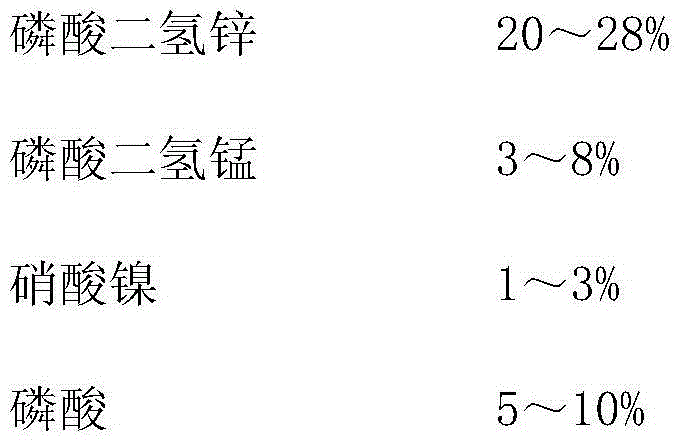

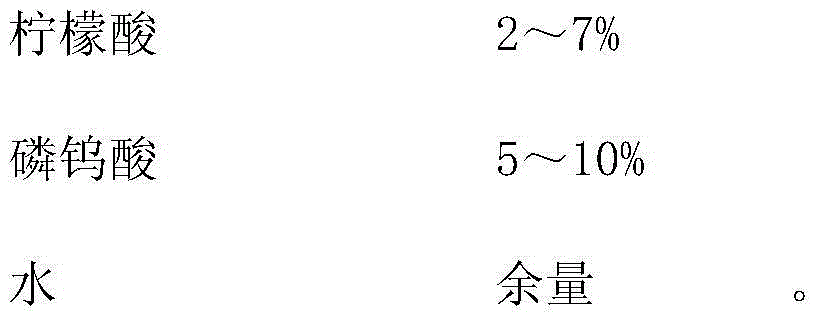

preparation example Construction

[0043] The preparation method of the above-mentioned NdFeB special surface treatment agent comprises the following steps:

[0044] (1) Add zinc dihydrogen phosphate and manganese dihydrogen phosphate into water, heat to 50°C, and stir to dissolve;

[0045] (2) Continue to add nickel nitrate, sodium fluoride, and sodium nitrate, stir and dissolve, and keep the temperature at 50°C for 0.5h;

[0046] (3) After the above liquid is cooled to normal temperature, phosphoric acid, citric acid, phosphotungstic acid and sodium molybdate are added to it, stirred evenly and completely dissolved, and then the preparation is completed.

[0047] The method of using the above-mentioned special surface treatment agent for NdFeB comprises the following steps:

[0048] (1) Use an alkaline degreasing machine to degrease the surface of the NdFeB magnetic material, and then clean the excess residual alkaline degreasing machine with clean water;

[0049] (2) Treat the NdFeB surface with a colloida...

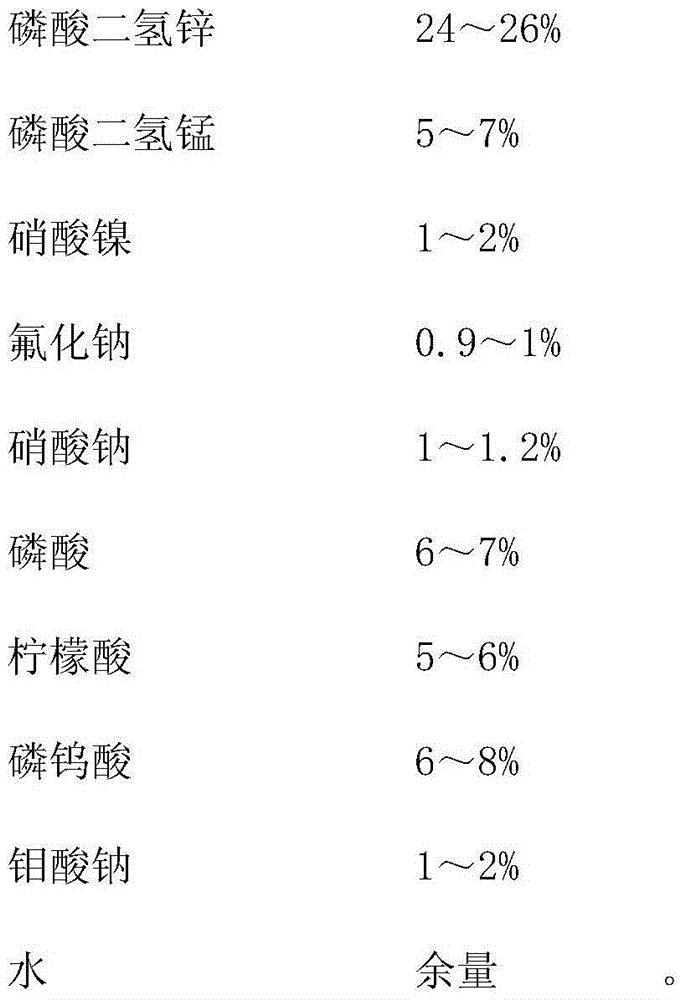

Embodiment 1

[0055]

[0056]

[0057] The units of the above components are grams.

[0058] The preparation method comprises the following steps:

[0059] (4) Add zinc dihydrogen phosphate and manganese dihydrogen phosphate into water, heat to 50°C, and stir to dissolve;

[0060] (5) Continue to add nickel nitrate, sodium fluoride, and sodium nitrate, stir and dissolve, and keep the temperature at 50°C for 0.5h;

[0061] After the above liquid is cooled to normal temperature, phosphoric acid, citric acid, phosphotungstic acid and sodium molybdate are added to it, stirred evenly and completely dissolved, and then the preparation is completed.

[0062] Surface treatment of NdFeB magnetic materials:

[0063] The material to be processed is the permanent magnet in the motor, and the equipment is soaked by an ultrasonic roller

[0064] The total acid point of the deionized solution of NdFeB special surface treatment agent is 40.2, and the free acid point is 7.1

[0065] (1) Use an alk...

Embodiment 2

[0071]

[0072] The units of the above components are grams. The preparation method is the same as in Example 1. Surface treatment of NdFeB magnetic materials:

[0073] The material to be processed is the permanent magnet in the motor, and the equipment is soaked by an ultrasonic roller

[0074] The total acid point of the deionized solution of NdFeB special surface treatment agent is 44.5, and the free acid point is 7.8

[0075] (1) Use an alkaline degreasing machine to degrease the surface of the NdFeB magnetic material, and then clean the excess residual alkaline degreasing machine with clean water;

[0076] (2) Treat the NdFeB surface with a colloidal titanium salt surface conditioner to form crystallization nuclei on the surface, laying a solid foundation for the next step to form a uniform and dense crystallization film on the surface;

[0077] (3) Dilute the NdFeB special surface treatment agent with deionized water to a 10% solution, then treat it at a temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com