Method for preparing high-orientation carbon nanotube film cooling fin

A carbon nanotube film and carbon nanotube array technology, which is applied in the field of preparation of high-oriented carbon nanotube film heat sinks, can solve the problems that limit the development of industrial applications, the complex preparation process, and the inconvenience of the batch preparation process of graphene heat sinks. Maturity and other issues, to achieve the effect of excellent physical and chemical stability, simple process and equipment, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

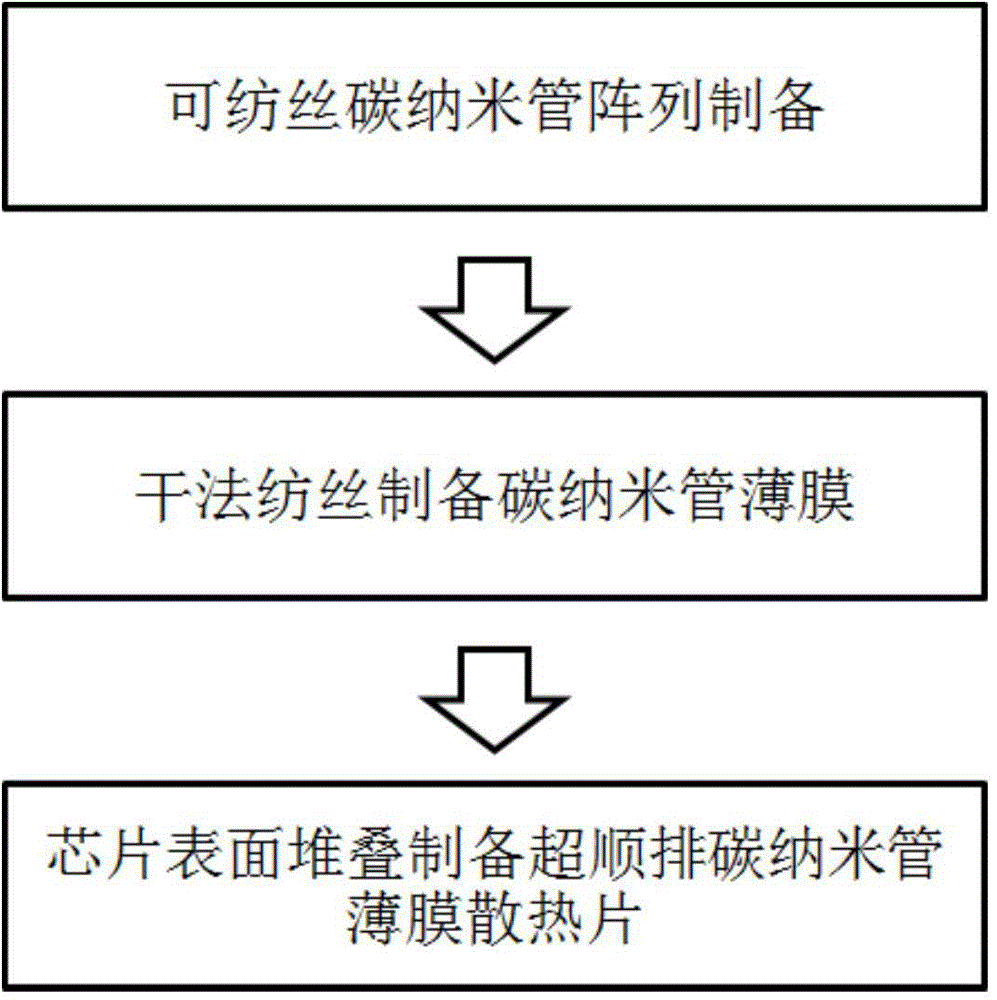

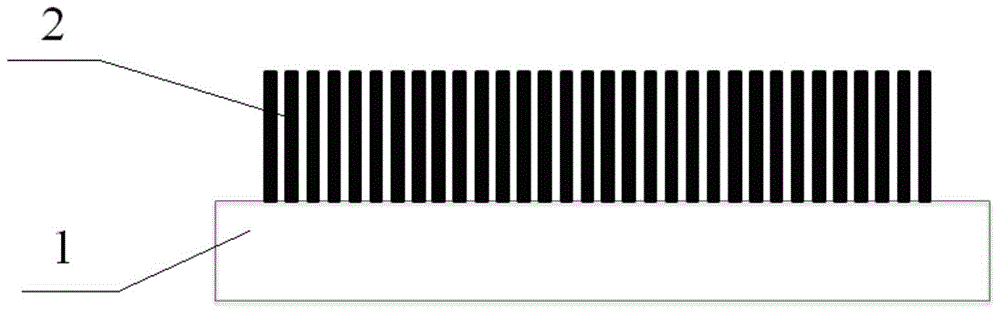

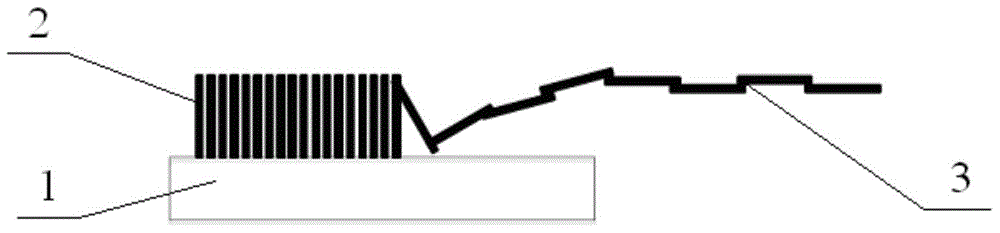

[0033] The preparation method of the highly oriented carbon nanotube thin film heat sink, the specific steps are as follows:

[0034] (1) Preparation of spinnable carbon nanotube arrays: super-aligned spinnable carbon nanotube array precursors, which are characterized in that the carbon nanotubes in the carbon nanotube array have a super-aligned structure perpendicular to the growth substrate; growth substrate selection 6 Inch substrate with silicon oxide silicon wafer; the catalyst uses a 0.3nm thick Fe catalyst film; the growth carbon source gas is ethylene gas;

[0035] The growth process includes: first, a 50nm thick aluminum oxide film is evaporated on the surface of a 6Inch silicon wafer substrate with an oxide layer by electron beam evaporation equipment, and then a 0.3nm thick aluminum oxide film is evaporated on the surface of aluminum oxide by electron beam evaporation equipment Iron catalyst film, that is, spinnable carbon nanotube array growth catalyst material.

...

Embodiment 2

[0042] The preparation method of the highly oriented carbon nanotube thin film heat sink, the specific steps are as follows:

[0043] (1) Preparation of spinnable carbon nanotube arrays: super-aligned spinnable carbon nanotube array precursors, which are characterized in that the carbon nanotubes in the carbon nanotube array have a super-aligned structure perpendicular to the growth substrate; growth substrate selection 6Inch substrate with silicon oxide silicon wafer; the catalyst uses a 3nm thick Fe catalyst film; the growth carbon source gas is acetylene gas;

[0044] The growth process includes: first, a 3nm-thick iron catalyst film is evaporated on the surface of a 6Inch silicon wafer substrate with an oxide layer by means of an electron beam evaporation device to obtain a spinnable carbon nanotube array growth catalyst material. Put the above-prepared catalyst into the growth chamber of the tubular CVD growth equipment to raise the temperature. After the temperature rise...

Embodiment 3

[0050] The preparation method of the highly oriented carbon nanotube thin film heat sink, the specific steps are as follows:

[0051] (1) Preparation of spinnable carbon nanotube arrays: super-aligned spinnable carbon nanotube array precursors, which are characterized in that the carbon nanotubes in the carbon nanotube array have a super-aligned structure perpendicular to the growth substrate; growth substrate selection Quartz substrate; the catalyst uses a 2nm thick Fe catalyst film; the growth carbon source gas is ethylene gas;

[0052] The growth process includes: first evaporating a layer of 50nm thick aluminum oxide film on the surface of the quartz substrate by electron beam evaporation equipment, and continuing to evaporate a layer of 2nm thick iron catalyst film on the surface of the alumina surface by electron beam evaporation equipment to obtain Spinning carbon nanotube arrays to grow catalyst materials. Put the above-prepared catalyst into the growth chamber of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com