Granular adsorbent as well as preparation method and application of granular adsorbent in adsorption of ammonia nitrogen

A particle adsorbent and adsorbent technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of single composition, environmental pollution, poor ammonia nitrogen adsorption effect, etc., and achieve large adsorption capacity. , the adsorption effect is good, the effect of reducing the treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

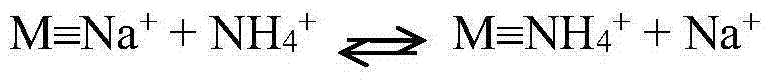

Problems solved by technology

Method used

Image

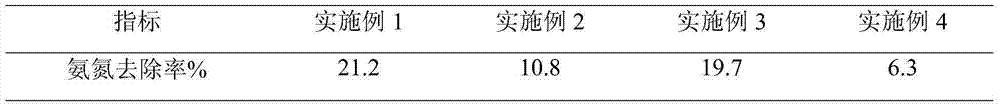

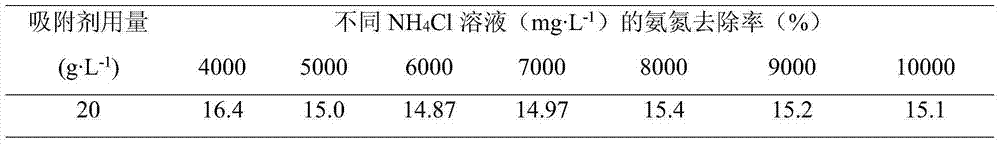

Examples

Embodiment 1

[0025] Mix 2g of red jade soil, 2g of Kanuma soil, 3g of natural zeolite powder, 2.5g of soluble starch, and 1g of sodium sulfate, add deionized water to make a paste, and artificially shape it into spherical particles with a diameter of 2–3mm. Dry for 24 hours, sinter in a muffle furnace at 600°C for 1.5 hours, cool to room temperature, and store directly in plastic PE bottles, sealed and kept at a constant temperature.

Embodiment 2

[0027] Mix 5g of red jade soil, 3.5g of montmorillonite, 3g of cornstarch, and 1.5g of sodium nitrate, add deionized water to make a paste, artificially form spherical particles with a particle diameter of 2-3mm, and dry at 90°C for 20h. Sinter in a muffle furnace at 400°C for 2h, cool to room temperature, and store directly in plastic PE bottles, sealed and kept at a constant temperature.

Embodiment 3

[0029] Mix 5g of deer marsh soil, 4g of bentonite, 1g of urea, and 2g of sodium chloride thoroughly, add deionized water to make a paste, artificially shape it into spherical particles with a particle diameter of 2–3mm, dry at 110°C for 24h, and place in a muffle furnace Sinter at 550°C for 1.5h, cool to room temperature, store directly in plastic PE bottles, seal and store at constant temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com