Method for preparing degradable material modified polylactic acid polymer

A polylactic acid polymer and polylactic acid technology are applied in the field of preparation of amino acid-modified polylactic acid polymers, which can solve the problems of limiting the molecular weight of the polymer, cumbersome preparation steps, low ring-opening activity, etc., and achieve lower synthesis costs and lower prices. source, effect of improving processability and biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

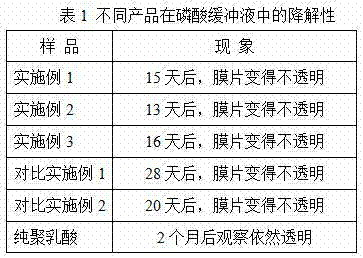

Examples

Embodiment 1

[0013] Under a nitrogen atmosphere, add lactic acid, 6-aminocaproic acid, hydroxyproline, and aspartic acid into water at a mass ratio of 60:80:10:5, first dehydrate under reduced pressure at 88°C, maintain for 2 hours, then raise the temperature Further heating and dehydration at 160°C completes, and continues to heat up to 220-230°C to react to obtain poly(lactic acid-amino acid) copolymer; the poly(lactic acid-amino acid) copolymer is mixed according to the mass ratio of 90:8 and the volume ratio is 90: Reflux in 10% chloroform / methanol mixed organic solvent, remove the organic solvent, then raise the temperature to 220°C to react to obtain amino acid-modified polylactic acid polymer.

Embodiment 2

[0015] Under a nitrogen atmosphere, add lactic acid, 6-aminocaproic acid, hydroxyproline, and aspartic acid into water at a mass ratio of 70:80:13:6, first dehydrate under reduced pressure at 85°C, maintain for 2 hours, then raise the temperature Further heating and dehydration to 165°C completes, and continues to heat up to 220-230°C to react to obtain poly(lactic acid-amino acid) copolymers; poly(lactic acid-amino acid) copolymers are mixed according to the mass ratio of 100:10 and the volume ratio is 90: Reflux in 10% chloroform / methanol mixed organic solvent, remove the organic solvent, then raise the temperature to 220°C to react to obtain amino acid-modified polylactic acid polymer.

Embodiment 3

[0017] Under a nitrogen atmosphere, add lactic acid, 6-aminocaproic acid, hydroxyproline, and aspartic acid into water at a mass ratio of 50:60:7:5, first dehydrate under reduced pressure at 85°C, maintain for 2 hours, then raise the temperature Further heating and dehydration to 160°C completes, and continues to heat up to 220-230°C to react to obtain poly(lactic acid-amino acid) copolymers; the poly(lactic acid-amino acid) copolymers are mixed according to the mass ratio of 95:10 and the volume ratio is 90: Reflux in 10% chloroform / methanol mixed organic solvent, remove the organic solvent, then raise the temperature to 220°C to react to obtain amino acid-modified polylactic acid polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com