Aurantiochytrium sp. YLH70 and application of Aurantiochytrium sp. YLH70 for synthesizing DHA

A technology of Schizochytrium and Jerusalem artichoke, applied in fungi, microorganism-based methods, microorganisms, etc., to achieve the effects of large yield, reduced production cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Isolation and Identification of Schizochytrium YLH70

[0024] (1) Isolation of strain YLH70

[0025] Collect rotten leaf samples at the seaside of Yueqing Bay, Wenzhou City, Zhejiang Province, wash and put in YP culture solution (1g / L yeast powder, 1g / L peptone, 50mg / L ampicillin, 50mg / L streptomycin) suspended on the surface with 0.1g pine pollen prepared in water, pH 6.0), cultured in the dark at 30°C for 1 week, took 50 μL of the culture and spread it on a YP plate (1g / L yeast powder, 1g / L peptone, 50mg / L ampicillin, 50mg / L streptomycin Agar 20g / L, water preparation, pH value 6.0), cultured at 28°C for 3 days until a single colony grew out, repeated streaking and purification culture three times to obtain a pure bacterial strain, which was designated as bacterial strain YLH70.

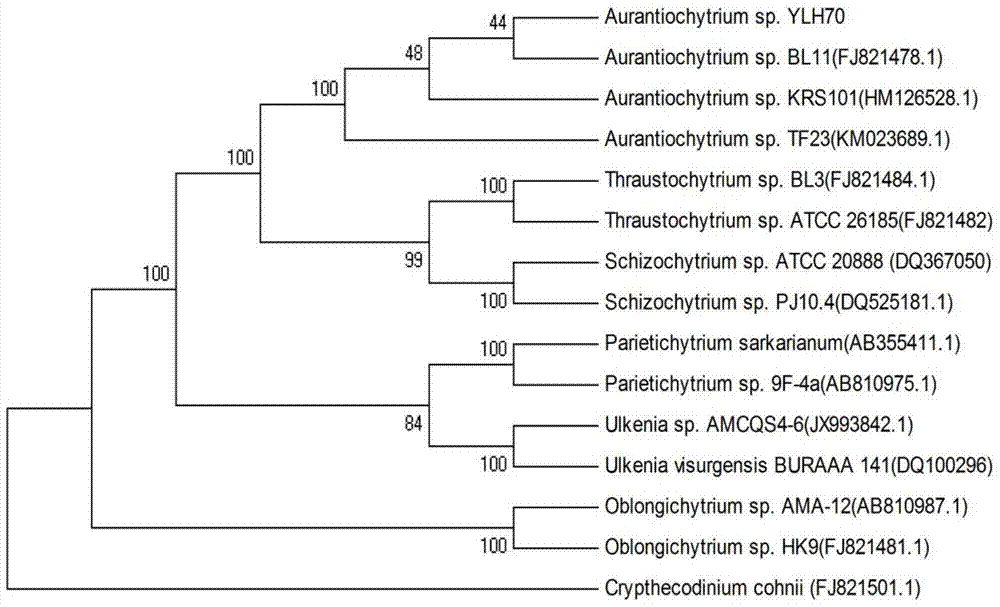

[0026] (2) Identification of strain YLH70

[0027] The strain YLH70 was inoculated on a YP plate, cultured at 28°C for 2 days, the colony was yellowish white, round, moist and smo...

Embodiment 2

[0029] The preparation of embodiment 2 Jerusalem artichoke hydrolyzate

[0030] About 5000g of fresh Jerusalem artichoke was washed, sliced, and placed in an oven at 80°C for 24h to dry. The dried Jerusalem artichoke chips are pulverized by a solid pulverizer, and filtered through a 60-mesh sieve to obtain Jerusalem artichoke powder. Weigh 1000g of Jerusalem artichoke powder, mix it with 3000mL of 3% aqueous sulfuric acid solution, acidify at 80°C for 240min, filter to obtain Jerusalem artichoke juice (i.e. filtrate), adjust the pH to 6.0 with 1M NaOH aqueous solution. Add inulinase 40U / g Jerusalem artichoke powder, pectinase 2U / g Jerusalem artichoke powder, cellulase 10U / g Jerusalem artichoke powder to the filtrate, hydrolyze at a temperature of 50°C for 24 hours, filter to make Jerusalem artichoke hydrolyzate, and its reducing sugar concentration It is 145g / L, which is Jerusalem artichoke hydrolyzate.

Embodiment 3

[0031] The preparation of embodiment 3 Jerusalem artichoke hydrolyzate

[0032] Wash about 5000g of fresh Jerusalem artichoke, slice it, and place it in an oven at 40°C for 48h to dry. The dried Jerusalem artichoke chips are pulverized by a solid pulverizer, and filtered through a 60-mesh sieve to obtain Jerusalem artichoke powder. Weigh 3000g of Jerusalem artichoke powder, mix it with 3000mL of 10% sulfuric acid aqueous solution, acidify at 100°C for 30min, filter to obtain Jerusalem artichoke juice, and adjust the pH to 6.0 with 1M NaOH aqueous solution. Add inulinase 5U / g Jerusalem artichoke powder, pectinase 0.5U / g Jerusalem artichoke powder, cellulase 10U / g Jerusalem artichoke powder to the Jerusalem artichoke juice, hydrolyze it at a temperature of 30°C for 48 hours, filter to make a Jerusalem artichoke hydrolyzate, and reduce The sugar concentration was 256g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com