Analysis method of organic matters in trichloracetic aldehyde waste sulfuric acid

A technology of trichloroacetaldehyde and analysis method, which is applied in the field of analytical chemistry, can solve the problems of no analysis of trichloroacetic acid content, high sampling requirements, single determination, etc., and achieve the effect of rapid detection, high separation efficiency and accurate quantification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The initial temperature of the chromatographic column of the gas chromatograph in the present invention is room temperature, the temperature is raised to 100-200°C at a heating rate of 10°C / min, and the carrier gas flow rate is 1-3mL / min. In order to meet the complete separation of the peaks of the internal standard and all the components in the sample, combined with the boiling point of each substance, determine the optimal chromatographic analysis conditions as follows:

[0026] Chromatographic analyzer analysis conditions

[0027] Chromatographic column: 30m×0.32mm SE-54 chromatographic column; carrier gas: N 2 ; Carrier gas flow rate: 1mL / min; Chromatographic column temperature: 120°C; Injection volume: 0.4μL; Vaporization chamber temperature: 250°C;

Embodiment 2

[0029] (1) Preparation of standard solution: Dissolve 0.10g, 0.20g, 0.30g, 0.40g, and 0.50g of chloral in ethanol and add it to a 10mL volumetric flask. Chloroacetaldehyde standard solution. The standard solution preparation method of ethyl trichloroacetate and diethyl sulfate is the same as the preparation method of chloral standard solution.

[0030] (2) Preparation of internal standard solution: Accurately weigh 0.20 g of p-xylene, add it to a beaker, and add an appropriate amount of ethanol. Shake well and add to a 10mL volumetric flask, add ethanol to make up to the mark. After shaking and shaking, a 20 mg / mL p-xylene solution was obtained.

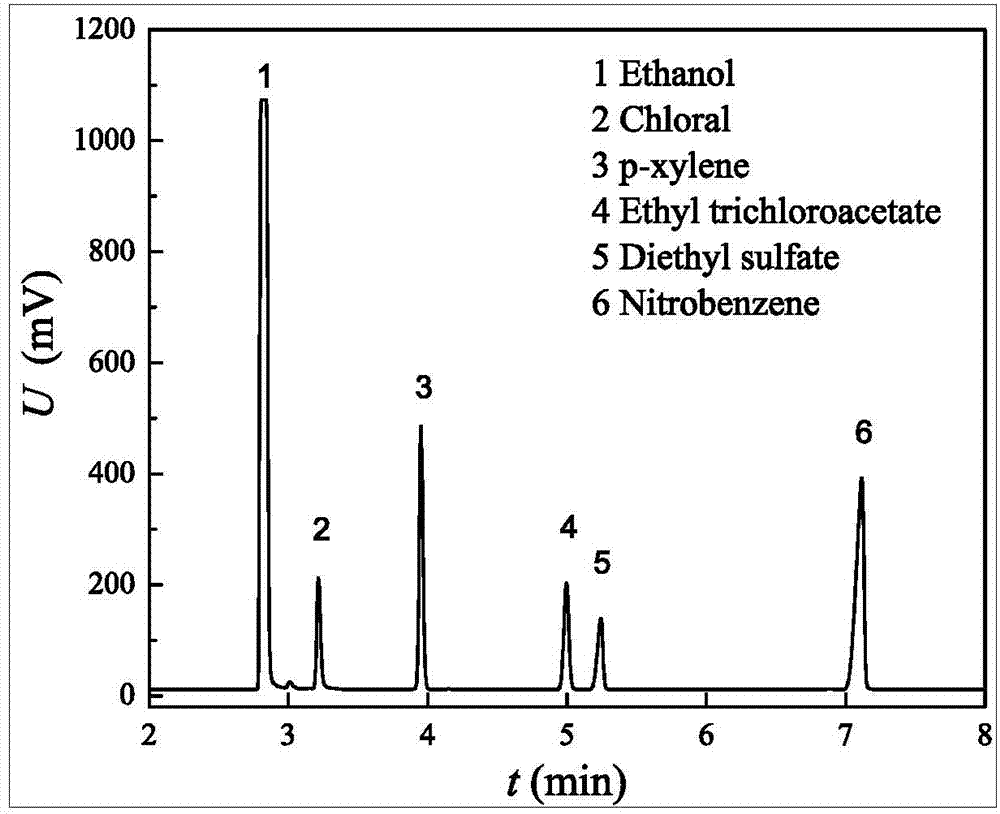

[0031] (3) Determination of the retention time of organic matter: take 0.5 mL each of the above-mentioned 20.0 g / L standard solution and internal standard solution, mix well, inject a sample into the chromatograph with a syringe, carry out qualitative analysis, and obtain the solvent under the above-mentioned chromatographic condit...

Embodiment 3

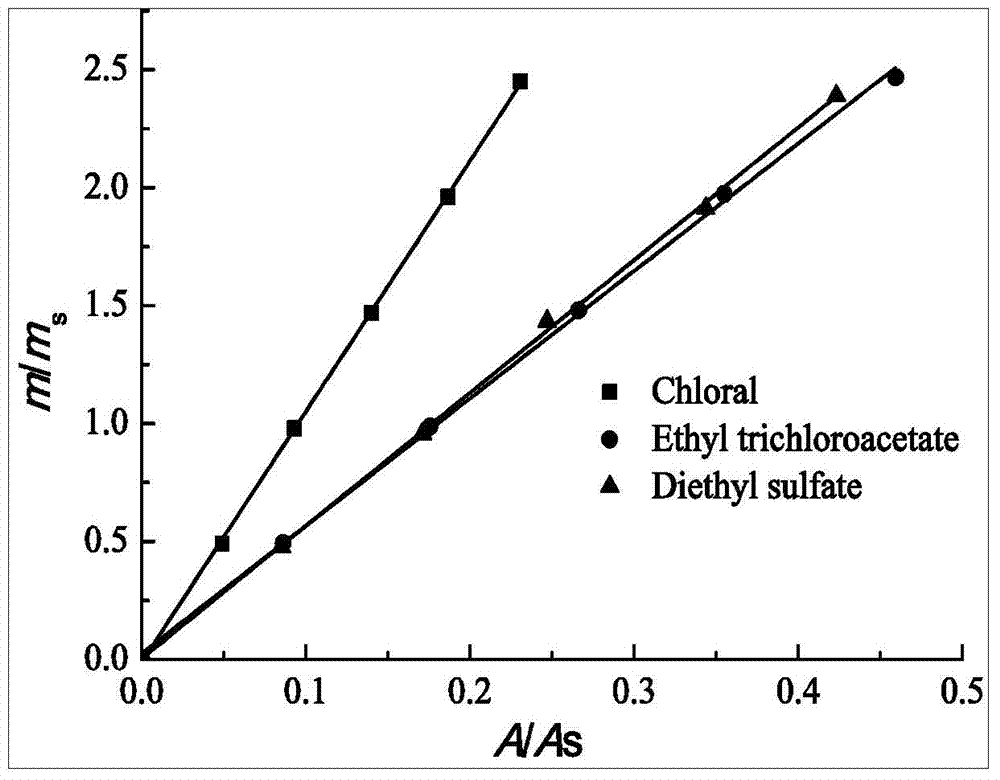

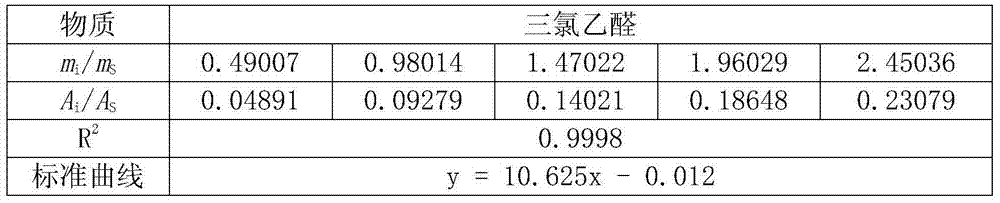

[0033] The drawing of the standard curve: the chromatographic column is passed through the carrier gas N 2 After aging for 24 hours, pass gas H 2 And auxiliary gas (compressed air), gas H2 The volume ratio with the supporting gas is controlled at 1:10, adjust the parameters of the gas chromatograph as shown in the examples, and ignite after constant temperature for half an hour. Measure 2mL of the standard solution and 1mL of the internal standard solution prepared in Example 2 respectively, add them to a 5mL volumetric flask, dilute to the mark with ethanol, mix evenly, take 0.4 μL of the mixed solution with a 0.5 μL microsampler, and use Analyzed by gas chromatography, draw a standard curve according to the data obtained by the N2000 chromatographic workstation, after a group of samples are injected 5 times for parallel analysis, take the average value, according to m i / m S (the ratio of the mass of the sample to the mass of the internal standard substance) and A i / A S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com